Feb . 12, 2025 23:16 Back to list

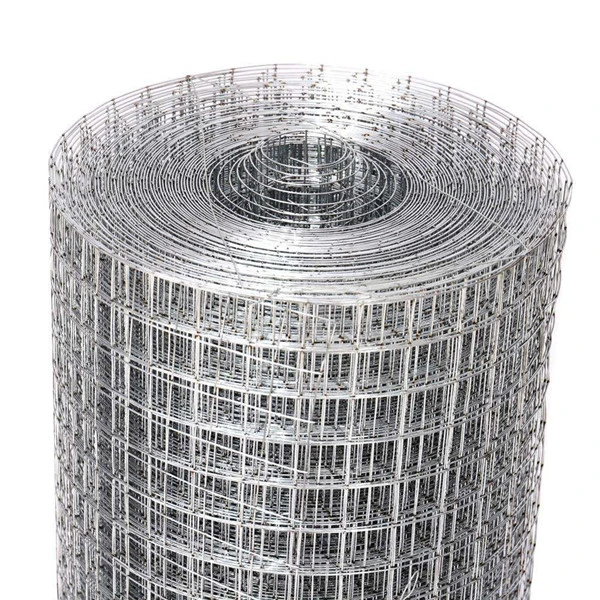

galvanized chicken wire mesh

The W4 x W4 wire mesh is a versatile and indispensable product in various industries, known for its robustness and adaptability. It’s commonly used in construction projects, reinforcing concrete structures, and even in artistic installations. Understanding the intricacies of this wire mesh is crucial for professionals seeking reliable and efficient materials.

In terms of authoritativeness and industry standards, W4 x W4 wire mesh complies with national and international guidelines for construction materials. It undergoes rigorous testing to meet tensile strength, durability, and corrosion resistance parameters, ensuring compliance with all safety regulations. This rigorous adherence to standards is not only a testament to its quality but also provides peace of mind to construction managers and architects who rely on its performance each day. Trustworthiness is further solidified by the mesh's track record in successful applications worldwide. Its use in both residential and commercial projects speaks volumes about its reliability. Many leading construction firms have integrated W4 x W4 wire mesh into their standard operations, influenced by its proven ability to enhance the longevity and strength of the buildings. Testimonials from industry veterans reflect a consensus on its dependability. In summary, W4 x W4 wire mesh stands out as a superior choice due to its blend of strength, flexibility, and compliance with regulatory standards. It empowers industry professionals with a reliable tool for reinforcing concrete structures, ultimately ensuring safer and more resilient builds. As both practical and innovative, it continues to set benchmarks in construction, reinforcing the importance of quality materials in the industry.

In terms of authoritativeness and industry standards, W4 x W4 wire mesh complies with national and international guidelines for construction materials. It undergoes rigorous testing to meet tensile strength, durability, and corrosion resistance parameters, ensuring compliance with all safety regulations. This rigorous adherence to standards is not only a testament to its quality but also provides peace of mind to construction managers and architects who rely on its performance each day. Trustworthiness is further solidified by the mesh's track record in successful applications worldwide. Its use in both residential and commercial projects speaks volumes about its reliability. Many leading construction firms have integrated W4 x W4 wire mesh into their standard operations, influenced by its proven ability to enhance the longevity and strength of the buildings. Testimonials from industry veterans reflect a consensus on its dependability. In summary, W4 x W4 wire mesh stands out as a superior choice due to its blend of strength, flexibility, and compliance with regulatory standards. It empowers industry professionals with a reliable tool for reinforcing concrete structures, ultimately ensuring safer and more resilient builds. As both practical and innovative, it continues to set benchmarks in construction, reinforcing the importance of quality materials in the industry.

Pervious:

Latest news

-

Why a Chain Link Fence is the Right Choice

NewsJul.09,2025

-

Upgrade Your Fencing with High-Quality Coated Chicken Wire

NewsJul.09,2025

-

The Power of Fence Post Spikes

NewsJul.09,2025

-

The Best Pet Enclosures for Every Need

NewsJul.09,2025

-

Secure Your Property with Premium Barbed Wire Solutions

NewsJul.09,2025

-

Enhance Your Construction Projects with Quality Gabion Boxes

NewsJul.09,2025

Products categories

NEED HELP?

Don' t Hesitate To Contact Us For More Information About Company Or Service

CONTACT US