Feb . 12, 2025 23:53 Back to list

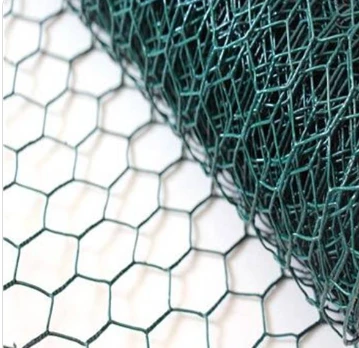

galvanized chicken wire mesh

When considering materials for durable and versatile construction applications, few options match the effectiveness and reliability of w4x4 wire mesh. This product epitomizes strength, flexibility, and utility, making it indispensable across multiple industries. Not only does it serve as a foundational element in modern construction, but it also provides an exemplary balance between cost-effectiveness and performance.

There is also an aesthetic appeal to w4x4 wire mesh. Architects and designers incorporate it into building facades or interior designs to create visually compelling textures and patterns. Its industrial look blends seamlessly with modern and minimalist aesthetics, making it a popular choice in urban dwellings. Additionally, when used in projects such as green walls, the mesh serves as an ideal climbing structure for plants, merging functional design with environmental sustainability. While the advantages of using w4x4 wire mesh are evident, understanding its proper specification and installation is crucial. Engaging with professionals who possess expertise in wire mesh applications ensures that projects adhere to structural and safety standards. Moreover, informed purchasing decisions regarding material grade and coating can greatly enhance the performance of the mesh in specific environments. Zinc-coated or PVC-coated options, for example, offer added protection against corrosive elements, making them suitable for maritime or chemically intense sites. In terms of authoritative insight, industry standards such as those set by ASTM or ISO are frequently consulted to guarantee that w4x4 wire mesh products meet stringent criteria for tensile strength and durability. Reliable manufacturers provide certification that is crucial for compliance in governmental or large-scale commercial projects. Thus, selecting certified products not only bolsters trust but also ensures adherence to contractual and safety obligations. Hence, the adoption of w4x4 wire mesh in various projects underscores its importance as a versatile building material. It demonstrates the balance of utility and aesthetics, accommodating both robust industrial applications and intricate design projects. Stakeholders who prioritize quality and dependability continue to favor w4x4 wire mesh, knowing it stands as a testament to durable, trustworthy engineering. Consequently, it remains a staple resource across sectors, poised to meet the evolving demands of contemporary and future projects.

There is also an aesthetic appeal to w4x4 wire mesh. Architects and designers incorporate it into building facades or interior designs to create visually compelling textures and patterns. Its industrial look blends seamlessly with modern and minimalist aesthetics, making it a popular choice in urban dwellings. Additionally, when used in projects such as green walls, the mesh serves as an ideal climbing structure for plants, merging functional design with environmental sustainability. While the advantages of using w4x4 wire mesh are evident, understanding its proper specification and installation is crucial. Engaging with professionals who possess expertise in wire mesh applications ensures that projects adhere to structural and safety standards. Moreover, informed purchasing decisions regarding material grade and coating can greatly enhance the performance of the mesh in specific environments. Zinc-coated or PVC-coated options, for example, offer added protection against corrosive elements, making them suitable for maritime or chemically intense sites. In terms of authoritative insight, industry standards such as those set by ASTM or ISO are frequently consulted to guarantee that w4x4 wire mesh products meet stringent criteria for tensile strength and durability. Reliable manufacturers provide certification that is crucial for compliance in governmental or large-scale commercial projects. Thus, selecting certified products not only bolsters trust but also ensures adherence to contractual and safety obligations. Hence, the adoption of w4x4 wire mesh in various projects underscores its importance as a versatile building material. It demonstrates the balance of utility and aesthetics, accommodating both robust industrial applications and intricate design projects. Stakeholders who prioritize quality and dependability continue to favor w4x4 wire mesh, knowing it stands as a testament to durable, trustworthy engineering. Consequently, it remains a staple resource across sectors, poised to meet the evolving demands of contemporary and future projects.

Pervious:

Latest news

-

Why a Chain Link Fence is the Right Choice

NewsJul.09,2025

-

Upgrade Your Fencing with High-Quality Coated Chicken Wire

NewsJul.09,2025

-

The Power of Fence Post Spikes

NewsJul.09,2025

-

The Best Pet Enclosures for Every Need

NewsJul.09,2025

-

Secure Your Property with Premium Barbed Wire Solutions

NewsJul.09,2025

-

Enhance Your Construction Projects with Quality Gabion Boxes

NewsJul.09,2025

Products categories

NEED HELP?

Don' t Hesitate To Contact Us For More Information About Company Or Service

CONTACT US