Feb . 12, 2025 22:40 Back to list

galvanized chicken wire mesh

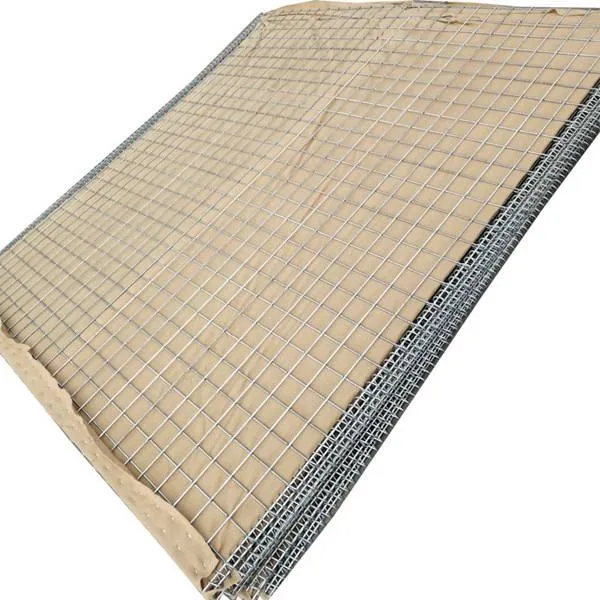

Unveiling the Power and Versatility of W4 Wire Mesh

Architectural Versatility Architects and designers are particularly fond of W4 wire mesh due to its versatility. Whether used in sleek, modern construction or more traditional builds, this material can be shaped and manipulated to complement any design vision. Sustainability In today's eco-conscious world, W4 wire mesh stands out as an environmentally friendly option. It is recyclable, reducing waste and promoting sustainable building practices. Experience and Expertise with W4 Wire Mesh Experienced engineers and construction professionals often share positive testimonials about working with W4 wire mesh. Its ease of installation often translates to time and cost savings on site. Moreover, its adaptability aids quick modifications should project specifications change, enhancing construction efficiency. Professionals in the field praise the mesh for its role in structural reinforcement, where it consistently outperforms traditional rebar reinforcement in terms of load distribution and installation speed. Construction experts underscore the mesh’s reliability in both large-scale commercial developments and smaller residential projects. Authority and Trust in Industry Standards W4 wire mesh has earned a reputation for meeting stringent industry standards, thus reflecting its quality and safety assurance. Manufacturers of W4 wire mesh are often certified and follow rigorous quality control processes to ensure each roll meets the required safety and performance benchmarks. This adherence to high standards builds trust among industry professionals and end-users alike. The Future of W4 Wire Mesh The demand for W4 wire mesh continues to grow as industries recognize its potential and versatility. Future innovations are likely to enhance its properties even further, such as improving its tensile strength or introducing even more corrosion-resistant alloys. As the construction and design industries lean towards more sustainable practices, W4 wire mesh is set to play an instrumental role in shaping structures that are not only durable and reliable but also environmentally responsible. In conclusion, W4 wire mesh stands out as a crucial component across a diversity of applications due to its unique blend of strength, versatility, sustainability, and trust in performance. As this adaptable material continues to evolve and meet new challenges, its role in modern engineering and architecture will only continue to expand.

Architectural Versatility Architects and designers are particularly fond of W4 wire mesh due to its versatility. Whether used in sleek, modern construction or more traditional builds, this material can be shaped and manipulated to complement any design vision. Sustainability In today's eco-conscious world, W4 wire mesh stands out as an environmentally friendly option. It is recyclable, reducing waste and promoting sustainable building practices. Experience and Expertise with W4 Wire Mesh Experienced engineers and construction professionals often share positive testimonials about working with W4 wire mesh. Its ease of installation often translates to time and cost savings on site. Moreover, its adaptability aids quick modifications should project specifications change, enhancing construction efficiency. Professionals in the field praise the mesh for its role in structural reinforcement, where it consistently outperforms traditional rebar reinforcement in terms of load distribution and installation speed. Construction experts underscore the mesh’s reliability in both large-scale commercial developments and smaller residential projects. Authority and Trust in Industry Standards W4 wire mesh has earned a reputation for meeting stringent industry standards, thus reflecting its quality and safety assurance. Manufacturers of W4 wire mesh are often certified and follow rigorous quality control processes to ensure each roll meets the required safety and performance benchmarks. This adherence to high standards builds trust among industry professionals and end-users alike. The Future of W4 Wire Mesh The demand for W4 wire mesh continues to grow as industries recognize its potential and versatility. Future innovations are likely to enhance its properties even further, such as improving its tensile strength or introducing even more corrosion-resistant alloys. As the construction and design industries lean towards more sustainable practices, W4 wire mesh is set to play an instrumental role in shaping structures that are not only durable and reliable but also environmentally responsible. In conclusion, W4 wire mesh stands out as a crucial component across a diversity of applications due to its unique blend of strength, versatility, sustainability, and trust in performance. As this adaptable material continues to evolve and meet new challenges, its role in modern engineering and architecture will only continue to expand.

Pervious:

Latest news

-

Why a Chain Link Fence is the Right Choice

NewsJul.09,2025

-

Upgrade Your Fencing with High-Quality Coated Chicken Wire

NewsJul.09,2025

-

The Power of Fence Post Spikes

NewsJul.09,2025

-

The Best Pet Enclosures for Every Need

NewsJul.09,2025

-

Secure Your Property with Premium Barbed Wire Solutions

NewsJul.09,2025

-

Enhance Your Construction Projects with Quality Gabion Boxes

NewsJul.09,2025

Products categories

NEED HELP?

Don' t Hesitate To Contact Us For More Information About Company Or Service

CONTACT US