Sep . 25, 2024 17:06 Back to list

plastic coated tie wire

The Versatility of Plastic Coated Tie Wire

In the realm of construction, crafting, and various DIY projects, materials that offer flexibility, durability, and ease of use are always in demand. One such material that has gained popularity in recent years is plastic coated tie wire. This innovative product combines the strength of traditional tie wire with the protective and aesthetic benefits of a plastic coating. In this article, we will explore the various applications, benefits, and advantages of plastic coated tie wire.

What is Plastic Coated Tie Wire?

Plastic coated tie wire consists of a base metal wire which is coated with a layer of plastic, usually made from polyethylene or PVC. This coating serves multiple purposes it protects the metal wire from corrosion, enhances its durability, and adds a touch of color that can be visually appealing. The coating also provides a non-abrasive surface, making it safer for use in various settings, especially where it may come into contact with people or delicate materials.

Applications of Plastic Coated Tie Wire

1. Construction Industry One of the primary applications of plastic coated tie wire is in the construction industry. It is commonly used for tying rebars in concrete construction, ensuring structural integrity while preventing rust. The plastic coating adds a layer of protection that extends the life of the wire and helps maintain the quality of the concrete.

2. Gardening and Landscaping Plastic coated tie wire is also favored by gardeners and landscapers. It can be used to support plants, secure trellises, and create garden structures without damaging delicate plants. The variety of colors available allows for aesthetic integration into floral arrangements and landscape designs.

3. Craft and DIY Projects For hobbyists and crafters, plastic coated tie wire is a valuable tool. Its flexibility and strength make it ideal for creating intricate designs, building models, or even crafting jewelry. The coatings allow users to choose a color that suits their project, enhancing its overall visual appeal.

plastic coated tie wire

4. Electronics In the electronics industry, plastic coated tie wire is often employed for bundling and organizing cables. The non-conductive nature of the plastic coating adds an extra layer of safety, reducing the risk of electrical shorts and providing a tidy appearance.

Benefits of Using Plastic Coated Tie Wire

1. Corrosion Resistance The primary benefit of plastic coating is its ability to protect the underlying metal wire from the elements. This corrosion resistance is especially beneficial in outdoor applications where exposure to moisture and varying weather conditions can lead to rust and degradation.

2. Durability Plastic coated tie wire is designed to withstand tension and bending without breaking. This durability makes it suitable for various applications, from construction to gardening.

3. Safety The plastic coating adds a layer of safety, preventing sharp edges from cutting or scratching surfaces, and making it a safer option for use around children and pets.

4. Color Variety Available in a range of colors, plastic coated tie wire allows for customization and creativity in various projects. Whether you want to blend in with a garden or stand out in an art piece, there is likely a color to suit your needs.

Conclusion

Plastic coated tie wire is an incredibly versatile material that has numerous applications across different industries. Its combination of strength, durability, corrosion resistance, and aesthetic appeal makes it a go-to choice for professionals and DIY enthusiasts alike. Whether you are in construction, landscaping, crafting, or electronics, plastic coated tie wire can fulfill a variety of needs while providing a reliable and attractive solution. As industries continue to evolve, the demand for multi-functional materials like plastic coated tie wire is only expected to grow, paving the way for innovative applications in the future. If you haven’t yet integrated plastic coated tie wire into your projects, now might be the perfect time to explore its possibilities.

-

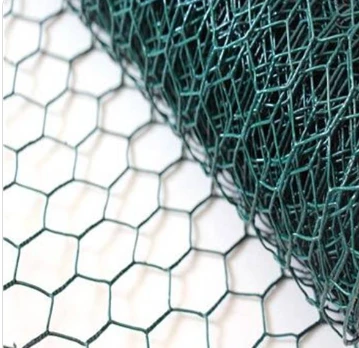

Leading PVC Hexagonal Wire Mesh Supplier | Durable & Cost-Effective

NewsAug.31,2025

-

Durable Galvanized Welded Wire Mesh Rolls for Fencing & Cages

NewsAug.30,2025

-

Durable Hexagonal Gabion Box | Erosion & Retaining Solutions

NewsAug.29,2025

-

Durable PVC Coated Wire Mesh for Sale | Weather & Corrosion Resistant

NewsAug.28,2025

-

Build a Discreet Chicken Run with Sturdy Green Coated Chicken Wire

NewsAug.23,2025

-

A Guide to Selecting the Most Durable Field Gates for Your Property

NewsAug.23,2025

Products categories