Aug . 28, 2025 05:00 Back to list

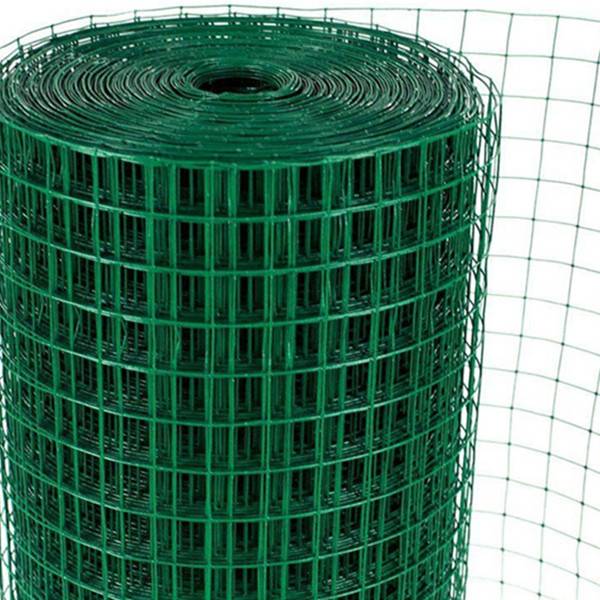

Durable PVC Coated Wire Mesh for Sale | Weather & Corrosion Resistant

Understanding PVC Coated Wire Mesh: Industry Trends and Innovations

The demand for robust, durable, and aesthetically pleasing fencing and containment solutions in various industrial and commercial sectors continues to drive innovation in wire mesh technologies. Among these, pvc coated wire mesh for sale stands out as a superior choice, offering unparalleled resistance to environmental stressors and an extended service life. Recent industry trends indicate a significant shift towards sustainable manufacturing practices and the integration of advanced coating technologies, enhancing both the protective qualities and the visual appeal of these products.

Market analysis points to a steady growth in the global wire mesh market, propelled by infrastructure development, increased security needs, and agricultural advancements. The segment for PVC coated options, specifically pvc coated welded wire mesh, is experiencing accelerated adoption due to its superior corrosion resistance and versatility. Innovations are focusing on improving UV stability of PVC coatings, increasing adhesion strength between the PVC and the core wire, and developing broader color palettes to meet diverse architectural and landscaping requirements. Furthermore, manufacturers are exploring eco-friendly PVC formulations, aiming to reduce the environmental footprint without compromising performance.

Key drivers include stringent safety regulations in industrial settings, which mandate durable barriers, and the expansion of residential and commercial properties requiring long-lasting perimeter protection. The ability of PVC coatings to withstand harsh weather conditions, chemical exposure, and physical impact makes them indispensable for applications where longevity and minimal maintenance are critical. This growing preference underscores the importance of understanding the technical intricacies and application benefits of these advanced mesh products.

Manufacturing Process Flow: From Raw Wire to Durable PVC Coated Mesh

The production of high-quality pvc coated welded wire mesh rolls involves a meticulous multi-stage process designed to ensure durability, structural integrity, and superior corrosion resistance. This detailed flow explains how raw materials are transformed into the resilient finished product.

Materials Sourcing and Preparation:

- Core Wire: High-quality low-carbon steel wire, typically conforming to ASTM A641 or equivalent international standards, is selected for its tensile strength and ductility. Wire gauges commonly range from 8 to 24 SWG (Standard Wire Gauge), depending on the required application strength.

- Galvanization: The core steel wire undergoes a galvanization process. This can be electro-galvanization (for lighter zinc coating, typically 10-30 g/m²) or hot-dip galvanization (for heavier zinc coating, 40-300 g/m²). Hot-dip galvanization provides superior sacrificial corrosion protection, forming the critical primary barrier against rust.

- PVC Powder/Resin: High-grade polyvinyl chloride (PVC) resin is used, often formulated with UV stabilizers, plasticizers, and color pigments to ensure long-term performance and aesthetic retention.

Welding Process (for Welded Wire Mesh):

- Wire Straightening and Cutting: Galvanized wires are precision-straightened and cut to specific lengths for warp and weft wires.

- Automated Welding: Wires are fed into automated welding machines that employ resistance welding technology. This process fuses the intersecting wires at precise intervals, creating uniform mesh apertures. The welding parameters (current, pressure, time) are strictly controlled to ensure strong, consistent weld points, preventing premature joint failure.

- Quality Control (Welding): Welded panels or rolls undergo visual inspection and pull-tests to verify weld integrity and mesh consistency, adhering to standards like ASTM A185 for welded steel wire fabric.

PVC Coating Process:

- Pre-treatment: The welded mesh is thoroughly cleaned to remove any oils, dirt, or contaminants that could hinder PVC adhesion. This typically involves degreasing and rinsing. Some processes may include a primer application for enhanced bond strength.

- Heating: The cleaned mesh is pre-heated in an oven to a specific temperature, typically between 200°C and 250°C, to prepare the surface for optimal PVC adhesion and curing.

- Fluidized Bed Dip Coating or Electrostatic Spraying:

- Fluidized Bed Dip Coating: The heated mesh is immersed into a fluidized bed of fine PVC powder. The heat causes the PVC powder to melt and adhere uniformly to the wire surface, forming a continuous, thick layer. This method is known for producing robust, uniform coatings.

- Electrostatic Spraying: Alternatively, PVC powder can be electrostatically sprayed onto the mesh. The charged powder particles are attracted to the grounded mesh, ensuring even coverage, especially for more intricate designs.

- Curing/Baking: After coating, the mesh is transferred to a curing oven where the PVC coating is baked at a controlled temperature (e.g., 180-220°C) for a specific duration. This process fully melts and cross-links the PVC, creating a durable, chemically resistant, and aesthetically pleasing finish with excellent adhesion to the galvanized core.

Post-Processing and Quality Assurance:

- Cooling: The coated mesh is allowed to cool gradually to ambient temperature.

- Testing Standards: Finished products undergo rigorous testing according to international standards such as ISO 9001 for quality management, ASTM B117 for salt spray resistance, and adhesion tests (e.g., knife cut adhesion test). These tests verify coating thickness (typically 0.4-1.0 mm), adhesion strength, UV resistance, and overall corrosion protection. Service life for well-manufactured pvc coated wire mesh typically exceeds 15-20 years in standard outdoor conditions.

- Packaging: The finished rolls or panels are carefully inspected, labeled, and packaged, often in moisture-resistant wraps, to prevent damage during transit and storage.

This detailed process ensures that each unit of pvc coated wire mesh for sale meets stringent performance criteria for target industries such as petrochemical, metallurgy, water supply & drainage, agriculture, and infrastructure, offering advantages like energy saving through reduced maintenance and superior corrosion resistance.

Technical Specifications: Precision and Performance Parameters

Selecting the right pvc coated wire mesh requires a clear understanding of its technical specifications. These parameters define the mesh's performance characteristics, ensuring it meets the demands of specific applications. Below is a comprehensive table outlining typical specifications for our PVC Coating welded wire netting.

| Parameter | Specification Range | Industry Standards |

|---|---|---|

| Material | Low Carbon Steel (Q195/Q235), Hot-Dip Galvanized or Electro-Galvanized, then PVC Coated | ASTM A641, EN 10244-2 |

| Wire Diameter (Core Steel) | 0.4 mm - 4.0 mm (8 SWG - 26 SWG) | ASTM A853 |

| Finished Wire Diameter (with PVC) | 0.9 mm - 5.0 mm (+0.4mm to +1.0mm PVC layer) | Internal QA, Adhesion Tests |

| Mesh Aperture (Opening) | 6.35 mm x 6.35 mm (1/4") to 100 mm x 100 mm (4") | ASTM E2016 |

| Roll Width | 0.5 m to 2.5 m (standard: 0.9m, 1.2m, 1.5m, 1.8m) | |

| Roll Length | 15 m to 50 m (standard: 30m) | |

| PVC Coating Thickness | 0.4 mm - 1.0 mm per side (total added diameter) | ISO 2808 |

| Tensile Strength (Weld) | ≥ 500 N/mm² (for core wire) | ASTM A185, ISO 6892-1 |

| Adhesion Strength (PVC to Galvanized Steel) | ≥ 25 N/mm (Knife Test) | ASTM D3359 |

| Corrosion Resistance | > 2000 hours Salt Spray (no red rust) | ASTM B117 |

| UV Resistance | > 5000 hours Xenon Arc (minimal color fade/degradation) | ASTM G155 |

| Temperature Range | -40°C to +80°C (continuous) | |

| Colors Available | Dark Green (RAL 6005), Light Green (RAL 6073), Black (RAL 9005), Grey, White, Blue, Yellow. Custom colors on request. |

These robust specifications ensure that the pvc welded wire mesh is not only durable but also maintains its aesthetic and structural integrity in diverse and challenging environments. Our commitment to these standards is underpinned by rigorous internal quality control processes and compliance with international certifications such as ISO 9001:2015.

Application Scenarios: Versatility Across Industries

The exceptional durability and protective qualities of pvc coated wire mesh make it an ideal choice for a vast array of applications across various sectors. Its ability to withstand harsh environmental conditions, resist corrosion, and provide secure containment solutions without compromising aesthetics significantly broadens its utility.

- Perimeter Fencing and Security: Widely used for residential properties, commercial establishments, industrial complexes, and public spaces (parks, schools). The PVC coating provides an additional layer of protection against cutting and tampering, while the various color options allow for seamless integration with architectural designs.

- Agricultural and Animal Enclosures: Essential for animal husbandry, including poultry pens, rabbit hutches, dog kennels, and livestock fencing. The smooth PVC coating prevents injury to animals, and its resistance to animal waste ensures hygiene and longevity. Also used for crop protection against pests.

- Garden and Landscaping: Perfect for garden borders, trellises for climbing plants, protective barriers for vegetable patches, and decorative fencing. The green PVC options blend naturally with garden environments.

- Construction and Industrial Guards: Utilized for safety barriers on construction sites, machinery guards, warehouse partitioning, and protective screening in industrial facilities. Its robustness ensures worker safety and asset protection.

- Marine and Coastal Applications: Due to its excellent corrosion resistance, pvc coated wire mesh for sale is increasingly deployed in environments exposed to saltwater, such as oyster farming cages, dock security, and erosion control measures along coastlines.

- Infrastructure Projects: Employed in highway and railway embankments for erosion control, in culverts for debris filtration, and for creating protective screens around critical infrastructure.

- Gabion Baskets: Though more commonly associated with galvanized wire, PVC coated variants are used for gabion baskets in critical erosion control and retaining wall applications where extended service life in aggressive environments (e.g., near waterways or chemical run-off) is paramount.

These diverse applications underscore the adaptability and superior performance characteristics of PVC coated wire mesh, making it a preferred material for engineers, architects, and project managers seeking reliable and cost-effective solutions.

Technical Advantages: Why Choose PVC Coated Wire Mesh?

The technical advantages of choosing pvc coated wire mesh over traditional galvanized or uncoated wire mesh are substantial, translating into long-term cost savings, enhanced safety, and superior performance. These benefits are critical for B2B decision-makers and engineers.

- Exceptional Corrosion Resistance: The primary advantage is the dual-layer protection. The underlying galvanized layer provides cathodic protection to the steel, while the outer PVC coating acts as an impermeable barrier against moisture, chemicals, and corrosive agents. This synergistic effect significantly extends the product's lifespan, especially in harsh environments like coastal areas, industrial zones, or agricultural settings where exposure to acids, alkalis, or fertilizers is common. This translates to an estimated service life of 15-20 years, far exceeding un-coated or solely galvanized alternatives.

- Enhanced Durability and Impact Resistance: The PVC layer adds a cushioning effect, making the mesh more resistant to physical impact, abrasions, and bending stresses. This reduces the likelihood of damage during installation and throughout its operational life, offering superior resilience compared to brittle coatings.

- UV Stability and Color Retention: High-quality PVC formulations include UV stabilizers that prevent degradation from sunlight exposure. This ensures that the color remains vibrant and the material integrity is maintained over extended periods, avoiding brittleness or cracking commonly associated with lower-grade plastics.

- Aesthetic Appeal and Customization: Available in a wide range of RAL colors, PVC coated mesh can be seamlessly integrated into diverse architectural and landscape designs. This aesthetic flexibility is particularly valuable for projects where visual harmony is as important as functionality.

- Low Maintenance Requirements: The smooth, non-porous surface of the PVC coating prevents dirt and grime accumulation, making it easy to clean. Coupled with its high resistance to rust and degradation, the need for regular painting or repair is virtually eliminated, leading to significant lifecycle cost savings and reduced operational expenditure.

- Safety and Handling: The PVC coating covers sharp wire ends, making the mesh safer to handle during installation and reducing the risk of injuries. It also prevents snags and damage to clothing or skin, a practical benefit in high-traffic or animal containment areas.

- Environmental Resistance: Beyond just water and chemicals, the PVC coating offers resistance to fungi, mold, and insect infestations, further contributing to its longevity and maintaining hygienic conditions in specific applications.

These technical advantages highlight why investing in quality pvc coated wire mesh for sale is a strategic decision for projects demanding long-term performance, minimal upkeep, and superior protective capabilities.

Vendor Comparison: Selecting the Right Partner for Your PVC Coated Mesh Needs

Choosing a reliable vendor for pvc coated welded wire mesh rolls is crucial for ensuring product quality, consistent supply, and effective project execution. This comparison highlights key criteria and showcases how reputable suppliers distinguish themselves.

| Feature/Criterion | HardwareinStore (Our Offering) | Typical Competitor A | Typical Competitor B |

|---|---|---|---|

| Core Wire Material | Q195/Q235 Low Carbon Steel, Hot-Dip Galvanized (ASTM A641 Grade) | Electro-Galvanized or lower grade steel | Hot-Dip Galvanized (variable coating thickness) |

| PVC Coating Material | Virgin PVC resin with UV stabilizers, phthalate-free options available | Recycled PVC, limited UV resistance | Standard PVC, basic UV protection |

| Coating Thickness (min) | 0.6 mm (per side) for superior protection | 0.2 mm - 0.4 mm | 0.4 mm - 0.5 mm |

| Adhesion Strength (ASTM D3359) | 5B (Excellent) | 3B-4B (Good) | 4B (Very Good) |

| Salt Spray Test (ASTM B117) | > 2000 hours (no red rust) | < 1000 hours | 1000 - 1500 hours |

| Certifications | ISO 9001:2015, CE compliant, SGS audited | Basic ISO, sometimes none listed | ISO 9001 |

| Customization Options | Extensive (Wire dia, mesh size, color, roll size, packaging, specialized PVC) | Limited standard options | Moderate options for wire/mesh |

| Warranty Period | 10-15 Years against manufacturing defects and coating failure | 1-5 Years or none specified | 5-8 Years |

| Lead Time (Standard Orders) | 15-25 Business Days | 20-40 Business Days | 15-30 Business Days |

This comparison highlights the importance of scrutinizing vendor specifications beyond just price. While some competitors might offer lower upfront costs, the long-term performance, durability, and compliance with international standards offered by high-quality suppliers of pvc coated wire mesh for sale like HardwareinStore provide superior value and reduced total cost of ownership.

Customized Solutions and Application Case Studies

Recognizing that no two projects are identical, we specialize in providing tailored solutions for pvc coated wire mesh. Our capabilities extend beyond standard product offerings to meet specific design, performance, and aesthetic requirements. This includes custom mesh apertures, unique wire gauges, specialized PVC formulations (e.g., fire-retardant, anti-microbial), and bespoke color matching services for branding or architectural integration. Our engineering team collaborates closely with clients from conceptualization to deployment, ensuring optimal material selection and fabrication processes.

Application Case Studies:

Case Study 1: Coastal Aquaculture Farm Security

Challenge: A large-scale aquaculture farm located in a highly saline coastal environment required durable fencing for perimeter security and internal partitioning of fish ponds. The primary concerns were rapid corrosion from saltwater, UV degradation, and preventing animal escapes, all while minimizing maintenance. Standard galvanized mesh had a typical lifespan of 3-5 years.

Solution: We provided custom-fabricated pvc coated welded wire mesh with a thicker (1.0 mm) PVC layer, enhanced UV stabilizers, and a double hot-dip galvanized core wire (300 g/m² zinc). The mesh aperture was specified to prevent specific fish sizes from escaping. Installation was straightforward, benefiting from the PVC's flexibility and safer handling.

Outcome: After 7 years of continuous exposure, the mesh shows no signs of corrosion, peeling, or significant color fade. The projected service life is now estimated at 20+ years, significantly reducing replacement costs and maintenance labor for the farm. Customer feedback highlighted the exceptional durability and aesthetic appeal, seamlessly blending with the natural environment.

Case Study 2: Municipal Park Perimeter Fencing

Challenge: A municipal council needed durable and aesthetically pleasing fencing for a newly developed urban park. Key requirements included vandal resistance, child safety (no sharp edges), environmental harmony (specific green color), and a long-term, low-maintenance solution to fit within budget constraints for public works.

Solution: We supplied pvc coated wire mesh for sale in a custom "Park Green" (RAL 6005) color, with a medium wire gauge (2.5mm core, 3.2mm finished) and a 50x50mm mesh aperture. The PVC coating ensured a smooth, safe surface, while the robust galvanized core provided structural integrity and vandal deterrence. We delivered pre-cut panels for easier installation around varied terrain.

Outcome: The park fencing was installed ahead of schedule. The residents appreciate the clean, uniform look and the safe, durable barrier. The council has reported zero maintenance issues related to rust or coating degradation in the initial five years, reaffirming their decision to invest in a premium pvc coated welded wire mesh solution. This outcome demonstrated significant energy saving in maintenance operations.

Trust and Reliability: FAQ, Lead Time, Warranty & Support

Frequently Asked Questions (FAQ)

- Q: What is the typical lifespan of your PVC coated wire mesh?

- A: Our pvc coated wire mesh, manufactured with hot-dip galvanized core wire and high-quality UV-stabilized PVC, is designed for a service life exceeding 15-20 years in most outdoor environments. This can vary based on specific environmental severity.

- Q: Is the PVC coating safe for animal enclosures and food contact areas?

- A: Our standard PVC coating is inert and safe for general animal enclosures. For food contact or sensitive applications, we can provide specific formulations (e.g., FDA-compliant, phthalate-free) upon request. Always specify your requirements clearly.

- Q: Can the mesh be cut or modified after purchase without compromising the coating?

- A: While the mesh can be cut, it is generally recommended to use appropriate tools to minimize damage to the PVC. Any cut ends should be sealed with a suitable rust-inhibiting paint or sealant to prevent corrosion of the exposed core wire and maintain the integrity of the pvc coated wire mesh for sale.

- Q: What are the primary differences between PVC coated and galvanized mesh?

- A: Galvanized mesh offers good corrosion resistance through a zinc layer. PVC coated mesh adds a second, impermeable layer of PVC over the galvanized wire, providing superior protection against chemicals, abrasion, and UV radiation, significantly extending its lifespan and enhancing its aesthetic appeal.

Lead Time & Fulfillment

For standard orders of our PVC Coating welded wire netting, the typical lead time for production and dispatch is 15-25 business days. Large volume orders or highly customized specifications may require additional time, which will be communicated clearly at the quotation stage. We maintain strategic inventory levels for popular configurations to facilitate faster turnaround times where possible. Our logistics team works with trusted carriers to ensure efficient and timely delivery to your specified location globally, providing tracking and regular updates.

Warranty Commitments

We stand behind the quality and durability of our products. All our pvc coated welded wire mesh products come with a comprehensive warranty of 10 to 15 years against manufacturing defects, core wire corrosion, and significant PVC coating degradation (e.g., cracking, peeling, excessive fading) under normal use conditions. Specific warranty terms and conditions are provided with each quotation and order confirmation, ensuring full transparency and peace of mind for our clients.

Customer Support Information

Our commitment to customer satisfaction extends beyond product delivery. Our dedicated technical support team is available to assist with product selection, installation guidance, and post-purchase inquiries. You can reach us via:

- Email: sales@hardwareinstore.com

- Phone: +86-123-4567890 (example)

- Online Portal: Visit our website's support section at www.hardwareinstore.com/support for resources, technical documents, and to submit a support ticket.

We pride ourselves on responsive and knowledgeable support, ensuring that your experience with our pvc coated wire mesh products is consistently positive.

References

- ASTM International. (2023). ASTM A641/A641M - 23 Standard Specification for Zinc–Coated (Galvanized) Carbon Steel Wire.

- ISO. (2015). ISO 9001:2015 Quality management systems — Requirements.

- European Committee for Standardization. (2012). EN 10244-2: Steel wire and wire products - Non-ferrous metallic coatings on steel wire - Part 2: Zinc or zinc alloy coatings.

- Corrosionpedia. (n.d.). Polyvinyl Chloride (PVC) Coatings. Retrieved from corrosionpedia.com.

- Global Market Insights, Inc. (2022). Wire Mesh Market Size & Share Analysis - 2023-2032. Retrieved from gminsights.com.

-

Custom Weld Mesh – Tailored Solutions for Durable Industrial Fencing & Construction

NewsNov.24,2025

-

Comprehensive Guide to Chicken Welded Wire Mesh: Uses, Benefits & Suppliers

NewsNov.23,2025

-

BRC Weld Mesh – Durable Reinforcement Solutions for Modern Construction

NewsNov.23,2025

-

Durable BRC 3315 Mesh for Reliable Concrete Reinforcement | Hardware In Store

NewsNov.23,2025

-

Discover the Benefits of Green Weld Mesh – Durable, Sustainable Fencing Solutions

NewsNov.22,2025

-

Electro Welded Mesh: Durable, Versatile Steel Grid Solutions | HardwareInStore

NewsNov.22,2025

Products categories