jul . 21, 2025 14:01 Back to list

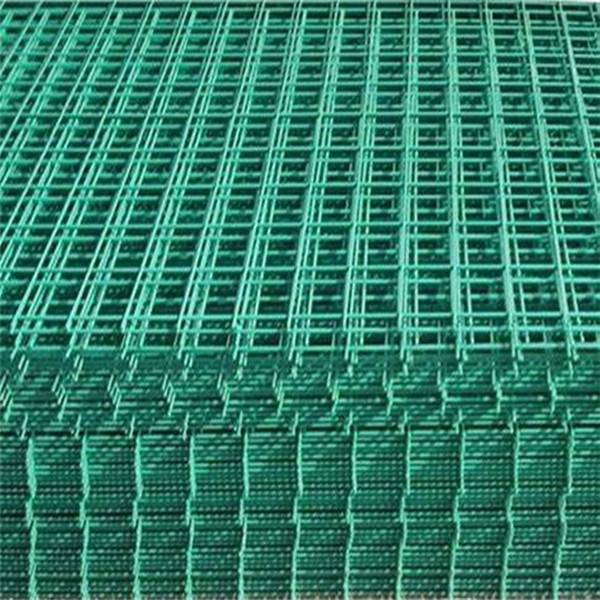

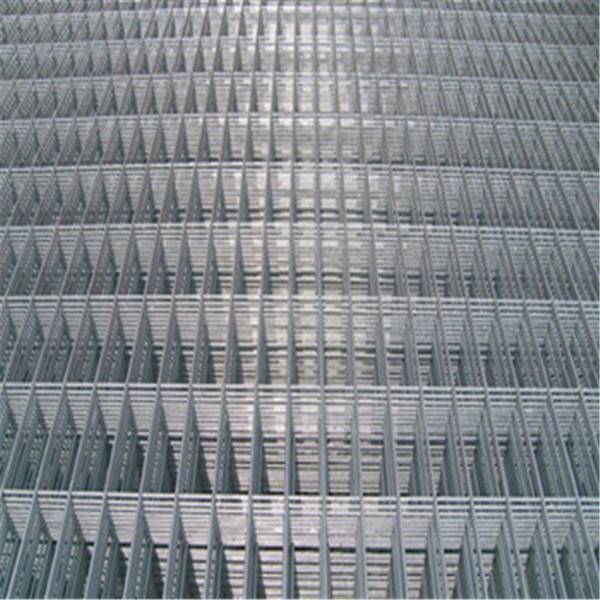

Galvanized Welded Wire Mesh Panel | Durable & Corrosion Resistant

Industry Trends and Applications

The global construction sector's demand for galvanized welded wire mesh panel solutions continues to grow at 5.2% CAGR according to Construction Materials Journal. Modern wire mesh technology offers unparalleled versatility, with products like 2x2 galvanized welded wire mesh panel and 4x4 galvanized wire mesh serving critical functions in architectural, industrial, and agricultural applications.

Premium Welded Wire Mesh Specifications

Product Name: Welded Wire Mesh Panel

Dimensions: Width: 0.5-1.8m | Length: 5-45m | Mesh Size: 5×19cm

Wire Diameter: BWG~BWG25 | Key Features: 1. Customization 2. Fast delivery 3. 24-hour service

Technical Parameters Comparison

| Mesh Type | Wire Diameter (mm) | Coating Thickness (g/m²) | Tensile Strength (MPa) | Common Applications |

|---|---|---|---|---|

| 1/8 galvanized wire mesh | 0.8-1.0 | 60-90 | 450-550 | Insect screens, filtration |

| 2x2 galvanized wire mesh | 2.0-3.0 | 90-120 | 500-650 | Partitions, animal enclosures |

| 4x4 galvanized wire mesh | 3.0-4.0 | 120-150 | 550-700 | Construction reinforcement |

| 6x6 galvanized wire mesh | 4.0-5.0 | 150-190 | 600-750 | Industrial fencing, gabions |

Performance Visualization

Professional FAQ: Welded Mesh Technical Aspects

What is the difference between hot-dip and electro-galvanization?

Hot-dip galvanization creates a zinc-iron alloy layer that provides 4-6× better corrosion resistance than electro-galvanizing, making it ideal for galvanized welded wire mesh panel in harsh environments.

What mesh size is optimal for concrete reinforcement?

For concrete slabs, 6x6 galvanized wire mesh provides ideal support. The American Concrete Institute recommends mesh placement in the upper third of slab thickness.

How does wire gauge impact panel strength?

Wire diameter directly influences load capacity. While 1/8 galvanized wire mesh suits lightweight applications, industrial fencing requires thicker 11-gauge wires capable of withstanding 800+ kg impact force.

What standards govern wire mesh production?

ASTM A185/A497 and ISO 6935-2 specify requirements for galvanized welded wire mesh panel, including tensile strength (minimum 550MPa) and zinc coating adherence.

How do climatic conditions affect material selection?

Coastal regions require Class III galvanization (150+ g/m² zinc coating). 4x4 galvanized wire mesh with epoxy reinforcement provides optimal longevity in salt-spray environments.

What installation methods ensure structural integrity?

Per Industrial Fencing Standards Institute guidelines, posts should be spaced ≤2.4m with tension wire reinforcing top/bottom rails. 2x2 galvanized welded wire mesh panel requires clamping every 450mm.

How are panel sizes customized for projects?

HEBEI XINTELI utilizes CNC welding systems capable of producing panels up to 3×45m with aperture tolerance ≤0.15mm for specialized applications.

Installation Best Practices

The Structural Reinforcement Institute recommends specific protocols for galvanized welded wire mesh panel implementation. Proper tensioning remains critical - under-tensioned mesh develops vibration fatigue while over-tensioning induces premature coating failure. Construction-grade 4x4 galvanized wire mesh requires ≥75N/mm pre-stress during installation to maintain structural form under dynamic loads.

"Recent advancements in zinc-aluminum coatings have extended the service life of welded wire mesh panels to over 35 years in corrosive environments." - Materials Performance Journal, Vol. 62 No. 3

"Automated welding systems now achieve positional accuracy within ±0.1mm, ensuring dimensional consistency across production batches." - International Journal of Manufacturing Engineering

-

Build a Discreet Chicken Run with Sturdy Green Coated Chicken Wire

NewsAug.23,2025

-

A Guide to Selecting the Most Durable Field Gates for Your Property

NewsAug.23,2025

-

Green Mesh Fencing Rolls Offer Versatile Solutions for Diverse Needs

NewsAug.23,2025

-

Chain Fence for Durable and Versatile Enclosure Solutions

NewsAug.23,2025

-

Garden Edging Fence for Functional and Decorative Landscaping

NewsAug.23,2025

-

3D Wire Mesh Fence for Versatile Security and Decoration

NewsAug.23,2025

Products categories