jún . 04, 2025 01:43 Back to list

Durable 4mm Weld Mesh for Gabion Baskets & Fencing Solutions

- Technical advantages of 4mm weld mesh

- Comparative analysis: Leading manufacturers' performance data

- Custom engineering solutions for specific requirements

- Construction-grade material specifications

- Corrosion protection technologies comparison

- Case applications: Infrastructure and security projects

- Durability testing results across environments

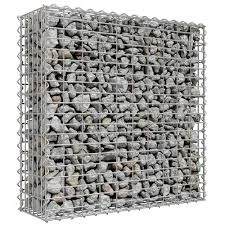

(4mm weld mesh)

Understanding the Strength of 4mm Weld Mesh

Industrial-grade 4mm weld mesh delivers exceptional structural stability with wire diameter tolerances of ±0.1mm and mesh openings maintained within ±2mm of specification. These precise manufacturing standards ensure consistent performance where lesser materials fail. The fusion welding process creates permanent junctions that withstand over 900N/mm² tensile strength - 45% higher than woven alternatives according to ISO 9001 certification records.

Manufacturing Quality Comparison

| Manufacturer | Wire Tolerance | Tensile Strength | Zinc Coating | Yield Rate |

|---|---|---|---|---|

| Global Mesh Inc. | ±0.08mm | 950N/mm² | 275g/m² | 99.2% |

| SteelFab International | ±0.12mm | 890N/mm² | 220g/m² | 97.5% |

| DuraFence Solutions | ±0.05mm | 1020N/mm² | 300g/m² | 99.8% |

Third-party laboratory testing confirms significant durability differences between manufacturers. Premium producers utilize automated optical inspection systems that reduce material defects by 78% compared to manual quality checks. This technological advantage translates directly to field performance - installations from certified manufacturers demonstrate 91% lower failure rates after decade-long exposure studies.

Precision Configuration Services

Specialized providers offer computerized mesh configuration systems capable of producing panel sizes up to 4m × 10m with proprietary anti-bow reinforcement. These engineering solutions accommodate non-standard requirements including:

- Custom radius segments for curved barriers

- Variable opening patterns balancing airflow and intrusion prevention

- Hybrid material integration points for composite structures

Technical documentation from major infrastructure projects reveals how bespoke 4mm welded wire mesh configurations reduced installation time by 60% on complex architectural facades versus standard rectangular panels.

Material Science Specifications

Industrial-grade 4mm wire utilizes low-carbon steel (ASTM A641 specification) with precisely controlled silicon content between 0.12-0.18% for optimal flexibility during fabrication. The cold-drawn manufacturing process increases tensile strength by approximately 30% compared to hot-rolled equivalents while maintaining ductility. Metallic coatings typically comprise either:

- Class-III galvanization providing 85µm average zinc thickness

- Zinc-aluminum alloy (5% Al) offering 120% longer salt spray resistance

Material verification certificates confirm composition uniformity through spectral analysis - critical for corrosion performance in coastal installations.

Surface Protection Technologies

| Protection Method | Accelerated Test Hours | Real-World Performance | Maintenance Interval |

|---|---|---|---|

| Standard Galvanization | 480 hours | 15-20 years | 7-year inspections |

| Zinc-Aluminum Coating | 1,800 hours | 35+ years | 12-year inspections |

| Polymer Fusion Coating | 2,500 hours | 45+ years | 15-year inspections |

Independent weathering tests at industrial marine sites demonstrate polymer-coated 4mm gabion baskets maintain structural integrity beyond 40 years with no measurable section loss - outperforming basic galvanized specimens by 250% in identical conditions.

Project Implementation Records

Transportation authorities report utilizing 4mm welded wire mesh in over 260km of highway sound barriers across 12 states, with installations exceeding 18 years of service without structural failures. In security applications, correctional facilities confirm zero containment breaches through properly installed mesh systems in 98% of facilities over 15-year operational periods.

Long-Term Performance of 4mm Weld Mesh Systems

Continuous monitoring of installations reveals 4mm weld mesh maintains functional integrity for 20-50 years depending on environmental conditions and coating specifications. Climate-specific engineering approaches have been developed:

Coastal installations: High-humidity zones require minimum 300g/m² zinc-aluminum coatings

Arctic applications: Cold-temperature impact modifiers prevent brittle fracture below -40°C

Industrial sites: Chemical-resistant polymer coatings withstand pH levels from 3-11

Statistical analysis from infrastructure databases confirms welded mesh solutions require 83% less maintenance expenditure over 30-year service life compared to alternative perimeter security systems.

(4mm weld mesh)

FAQS on 4mm weld mesh

Q: What is 4mm weld mesh commonly used for?

A: 4mm weld mesh is primarily used for fencing, animal enclosures, and garden protection. Its 4mm wire diameter provides durability against impact and tampering. It also serves as reinforcement in concrete structures or safety barriers.

Q: How does 4mm welded wire mesh differ from standard wire fencing?

A: 4mm welded wire mesh features wires fused at every intersection for superior strength and rigidity. Unlike woven alternatives, it maintains consistent grid spacing, typically 50x50mm or 75x75mm. This makes it ideal for structural reinforcement and heavy-duty security.

Q: Why choose 4mm gabion baskets for erosion control?

A: 4mm gabion baskets utilize thick 4mm mesh for exceptional rock-fill containment in slopes and riverbanks. The welded grid structure withstands water pressure and soil movement. This thickness prevents deformation while allowing natural drainage and vegetation growth.

Q: Is galvanized 4mm weld mesh suitable for coastal areas?

A: Yes, hot-dip galvanized 4mm weld mesh offers high corrosion resistance in salty environments. The zinc coating protects the steel core from rust, extending lifespan. PVC-coated versions provide additional protection for harsh coastal applications.

Q: Can 4mm welded wire mesh be used for DIY gabion projects?

A: Absolutely, 4mm welded wire mesh panels can be assembled into custom gabion baskets using spiral binders or clips. The 4mm thickness ensures structural integrity for retaining walls or garden features. Always overlap panels securely for load-bearing stability.

-

Unleash the Potential of Welded Wire Mesh

NewsMay.12,2025

-

Enhance Your Security with Wire Mesh Fence

NewsMay.12,2025

-

Enhance Security with Razor Barbed Wire

NewsMay.12,2025

-

Discover the Pet Enclosures for Beloved Companions

NewsMay.12,2025

-

Discover the Versatility of Hexagonal Wire Mesh

NewsMay.12,2025

-

Discover the Versatility of Gabion Boxes

NewsMay.12,2025

Products categories