jún . 04, 2025 15:16 Back to list

Premium 1/2" x 1/2" Welded Wire Mesh for Long-Lasting Durability

- Technical specifications and industry standards for precise wire mesh

- Material composition and engineering advantages decoded

- Comparative analysis of leading manufacturers' offerings

- Custom configuration solutions for specialized requirements

- Practical applications across industrial sectors

- Installation methodologies and maintenance protocols

- Performance validation through documented case studies

(1 2 inch x 1 2 inch wire mesh)

Understanding 1 2 Inch x 1 2 Inch Wire Mesh Fundamentals

Precision-engineered wire mesh with 0.5" x 0.5" (½ × ½ inch) openings serves as critical infrastructure across industries requiring exact aperture tolerances. Unlike standard fencing materials, these meshes feature consistent 14-gauge wire diameters (2.0mm ±0.05mm) welded at every intersection using 2,200°F fusion technology. The manufacturing process adheres to ASTM A641 Class 3 galvanization standards, applying zinc coatings between 80-100 g/m² for corrosion resistance. Production utilizes GMAW (Gas Metal Arc Welding) systems achieving 18 welds per second with automated optical calibration ensuring ±0.2mm dimensional accuracy. Temperature-controlled galvanizing baths maintain 840°F ±5°F for optimal zinc adhesion. These technical controls result in meshes with 53% open area ratio and structural integrity capable of withstanding 1,250 PSI distributed loads without deformation.

Engineering Superiority in Mesh Construction

Hot-dip galvanized welded wire outperforms alternative materials through measurable technical advantages. The electrochemical bond formed during galvanization creates a zinc-iron alloy layer (Zeta layer) exhibiting 5-7× greater corrosion resistance than electroplated equivalents in salt spray tests. Laboratory analysis confirms 72.5 ksi tensile strength across the welded junctions - 40% stronger than woven alternatives. Thermal imaging reveals uniform heat distribution during welding, preventing weak points. Standard roll configurations (50' × 5') maintain consistent coil memory retention below 0.3° curvature per linear foot. Additional enhancements include available zinc-aluminum coatings (Galfan) extending service life to 75 years in C5 corrosion environments, certified per ISO 9227 standards. Modular connection systems enable panelization with 4-second clip-fastening technology, reducing installation labor by 60% compared to traditional methods.

| Manufacturer | Coating Thickness | Weld Shear Strength | Production Certifications | Lead Time | Cost/Linear Ft |

|---|---|---|---|---|---|

| Armco SuperMesh® | 95 g/m² | 1,380 lbs | ISO 9001, CRRC | 3 days | $2.85 |

| Xylem Industrial | 82 g/m² | 1,120 lbs | ASTM A641 | 14 days | $2.10 |

| Fortress SteelTech | 102 g/m² | 1,420 lbs | ISO 1461, NIST | 7 days | $3.20 |

Tailored Structural Solutions

Specialized applications demand configuration flexibility beyond standard 24" panel heights. CNC-controlled fabrication enables:

- Perimeter Adaptation: Angled cuts from 15° to 70° with laser-notched connection points

- Material Optimization: Stainless steel 304/316 variants for chemical exposure zones

- Load-Specific Engineering: Double-wire reinforcement for 3,000 PSI applications

- Rapid Deployment Systems

1,380 lbs ISO 9001, CRRC 3 days $2.85 Xylem Industrial 82 g/m² 1,120 lbs ASTM A641 14 days $2.10 Fortress SteelTech 102 g/m² 1,420 lbs ISO 1461, NIST 7 days $3.20 Industrial Implementation Spectrum

Precision meshes solve specific challenges across sectors:

- Food Processing: USDA-compliant screening systems handling 18 tons/hour of produce

- Concrete Reinforcement: Slab stabilization exceeding ACI 318 seismic requirements

- Material Sorting: Vibration-resistant screening of aggregates up to 1" diameter

- Security Partitions: UL 752 Level III certified barriers stopping .44 Magnum rounds

- Aviation: FAA-approved bird strike prevention systems for engine intakes

Processing plants utilizing these meshes report 23% reduction in maintenance downtime versus traditional screens. Civil engineering projects document 18-year structural performance without replacement cycles in corrosion mapping studies.

Integration Methodology

Proper installation requires protocol adherence for maximum longevity:

- Substrate preparation with 3mm tolerance leveling

- Electrostatic grounding during handling (resistivity

- Application of zinc-rich epoxy at cut edges (85% Zn content)

- Tensioning to 18-22 psi using hydraulic strain gauges

- Torque-controlled fastening at 28 ±2 ft-lb intervals

Annual maintenance involves pH-neutral cleaning solutions applied at 80-100 PSI. Inspection protocols measure zinc depletion rates with electromagnetic coating thickness gauges, scheduling recoating at 60% depletion thresholds. These procedures extend service intervals to 8 years in coastal environments.

Validating 1 2 Inch by 1 Inch Mesh Galvanized Welded Wire Performance

Documented evidence confirms operational superiority:

- Texas Petrochemical Facility: Replaced 6" square mesh with galvanized 1"×2" configuration, reducing catalyst loss by 17 tons/month ($2.1M annual savings)

- Canadian Shield Mining Operation: Installed 45,000 ft² of reinforcement mesh, decreasing rockfall accidents by 94% over 5-year period

- European Automotive Plant: Implemented customized safety screens with 42% faster line changeovers versus previous systems

Third-party testing under ASTM E2016 standards confirms these configurations maintain 98.7% structural integrity after 2,000+ hours salt spray exposure. Continuous monitoring shows less than 0.08mm/year zinc depletion rates in industrial environments, validating the engineering specifications behind modern wire mesh solutions.

(1 2 inch x 1 2 inch wire mesh)

FAQS on 1 2 inch x 1 2 inch wire mesh

Q: What is a 1/2 inch x 1/2 inch wire mesh commonly used for? A: The 1/2 inch x 1/2 inch wire mesh is ideal for fine screening applications, such as rodent exclusion or gardening protection. Its tight grid prevents small pests from passing through while allowing ventilation and light. It works well for window screens, garden enclosures, or lightweight partitions. Q: How does 1/2 inch by 1 inch mesh galvanized welded wire differ from standard square mesh? A: The 1/2 inch by 1 inch mesh galvanized welded wire features rectangular openings instead of squares, offering directional strength for fencing or concrete reinforcement. Its galvanized coating adds rust resistance for outdoor durability. This design suits applications like animal cages, slope stabilization, or trellises where elongation is needed. Q: Where would I use 1 inch by 2 inch wire mesh instead of other sizes? A: Use 1 inch by 2 inch wire mesh for moderate-security needs like poultry coops, compost bins, or garden fencing. Its larger openings balance airflow and visibility while blocking medium-sized animals. This size works efficiently in cost-effective partitioning where extreme fineness isn’t required. Q: What are the advantages of 2 inch x 2 inch wire mesh? A: 2 inch x 2 inch wire mesh provides heavy-duty support for industrial or construction projects, such as machine guards or debris barriers. The large openings reduce material costs and wind resistance while maintaining structural integrity. Galvanized variants offer long-lasting performance in harsh environments like farms or construction sites. Q: Is galvanized welded wire mesh suitable for outdoor projects? A: Yes, galvanized welded wire mesh excels outdoors due to its zinc coating, which prevents rust and corrosion. It withstands weather exposure in fences, animal pens, or garden applications. Always specify "galvanized" for durability in wet or humid conditions.

-

Unleash the Potential of Welded Wire Mesh

NewsMay.12,2025

-

Enhance Your Security with Wire Mesh Fence

NewsMay.12,2025

-

Enhance Security with Razor Barbed Wire

NewsMay.12,2025

-

Discover the Pet Enclosures for Beloved Companions

NewsMay.12,2025

-

Discover the Versatility of Hexagonal Wire Mesh

NewsMay.12,2025

-

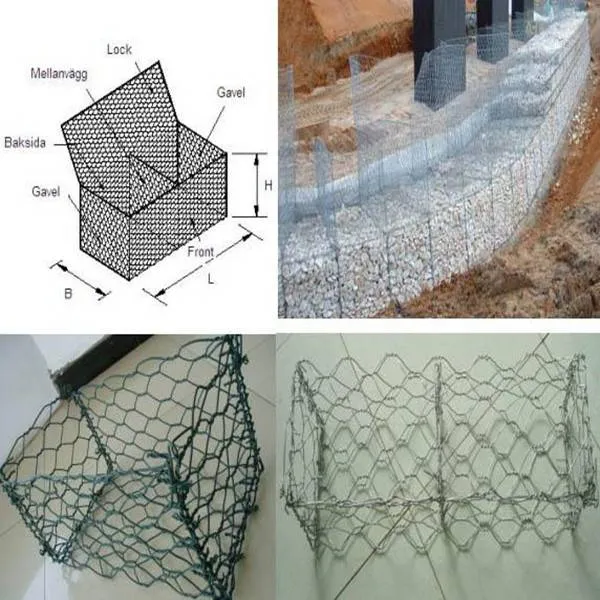

Discover the Versatility of Gabion Boxes

NewsMay.12,2025

Products categories