Jan . 25, 2025 04:32 Back to list

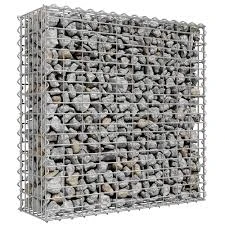

Galvanized Hesco Barrier Welded Gabion Box

Evaluating the costs associated with weld mesh brings into focus an essential aspect of modern construction and industrial projects. As the demand for durable and versatile building materials grows, understanding the financial aspects of weld mesh becomes crucial for making informed decisions. The overall cost of weld mesh is influenced by multiple factors, each with its own implications and potential savings.

Volume purchasing is a strategic approach to mitigate weld mesh costs. Bulk buying not only benefits from economies of scale but also often provides leverage for negotiation with suppliers. Larger orders might attract discounted rates, especially when suppliers aim to clear inventories or maintain continuous production cycles. Therefore, planning and forecasting project needs can unlock substantial financial benefits. Factoring in installation costs further refines the total expense picture. Skilled labor, necessary installation tools, and site preparation contribute additional layers to the budgeting process. Opting for professional installation ensures adherence to safety and quality standards, which though initially costlier, can avert long-term repair and non-compliance costs. Sustainability considerations are increasingly influencing the purchase decisions around weld mesh. With growing awareness and regulatory pressures surrounding eco-friendly building practices, selecting sustainably sourced or recycled materials may slightly increase upfront costs, but potentially qualify for environmental credits or enhance project appeal to environmentally conscious stakeholders. Ultimately, facing weld mesh cost challenges requires balancing between immediate financial capabilities and long-term project needs. Thoroughly assessing project requirements, material characteristics, and market conditions empowers decision-makers to choose the most cost-effective and suitable options. Making a well-informed choice not only aligns with fiscal responsibility but also achieves project goals without compromising quality and structural integrity.

Volume purchasing is a strategic approach to mitigate weld mesh costs. Bulk buying not only benefits from economies of scale but also often provides leverage for negotiation with suppliers. Larger orders might attract discounted rates, especially when suppliers aim to clear inventories or maintain continuous production cycles. Therefore, planning and forecasting project needs can unlock substantial financial benefits. Factoring in installation costs further refines the total expense picture. Skilled labor, necessary installation tools, and site preparation contribute additional layers to the budgeting process. Opting for professional installation ensures adherence to safety and quality standards, which though initially costlier, can avert long-term repair and non-compliance costs. Sustainability considerations are increasingly influencing the purchase decisions around weld mesh. With growing awareness and regulatory pressures surrounding eco-friendly building practices, selecting sustainably sourced or recycled materials may slightly increase upfront costs, but potentially qualify for environmental credits or enhance project appeal to environmentally conscious stakeholders. Ultimately, facing weld mesh cost challenges requires balancing between immediate financial capabilities and long-term project needs. Thoroughly assessing project requirements, material characteristics, and market conditions empowers decision-makers to choose the most cost-effective and suitable options. Making a well-informed choice not only aligns with fiscal responsibility but also achieves project goals without compromising quality and structural integrity.

Pervious:

Next:

Latest news

-

Why a Chain Link Fence is the Right Choice

NewsJul.09,2025

-

Upgrade Your Fencing with High-Quality Coated Chicken Wire

NewsJul.09,2025

-

The Power of Fence Post Spikes

NewsJul.09,2025

-

The Best Pet Enclosures for Every Need

NewsJul.09,2025

-

Secure Your Property with Premium Barbed Wire Solutions

NewsJul.09,2025

-

Enhance Your Construction Projects with Quality Gabion Boxes

NewsJul.09,2025

Products categories

NEED HELP?

Don' t Hesitate To Contact Us For More Information About Company Or Service

CONTACT US