Jan . 21, 2025 03:54 Back to list

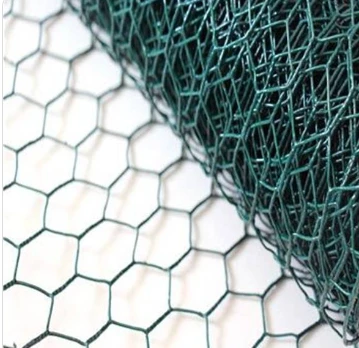

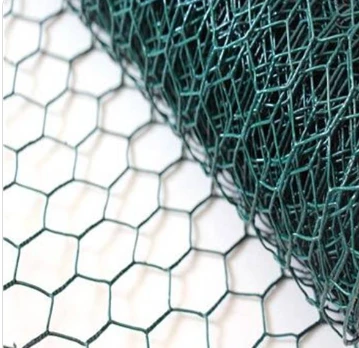

gabion welded wire mesh

Welded wire mesh netting is transforming various industries with its versatility, strength, and reliability. As a seasoned professional, I have witnessed firsthand the wide range of applications where this material excels. Understanding why it has become a staple in construction, agriculture, and industrial sectors will offer insights into its increasing popularity.

Technical specifications underscore the expertise behind welded wire mesh netting. High-quality materials, such as stainless steel or galvanized carbon steel, are selected to endure environmental stressors. Moreover, specialized coatings can be applied to extend its lifespan and expand its utility across multiple domains. A material scientist elaborated on advanced manufacturing techniques that refine these meshes for particular purposes, highlighting the ongoing innovation within the industry. Welded wire mesh netting is also heavily regulated, cementing its authority in sectors where compliance with safety and quality standards is non-negotiable. Certifications from reputable standard organizations ensure that the products meet specific load-bearing and durability benchmarks. Engineers and project managers can reference these standards to make informed decisions regarding their applications, further instilling confidence in their projects' success. Trustworthiness is inherent in its simplicity and functionality. It requires minimal maintenance and boasts a lifecycle that outlasts many alternative materials. Customers have expressed satisfaction due to its consistent performance and the peace of mind it offers when used in critical applications. Suppliers with a proven track record often provide warranties, further cementing consumer trust. In conclusion, welded wire mesh netting stands as a testament to modern innovation and reliability. It bridges gap between various fields, offering practical, efficient, and reliable solutions. Its role in reinforcing structures, protecting agricultural investments, and ensuring industrial safety cannot be understated. Experts in each respective domain rely on its dependability, cementing its status as an irreplaceable component in their professional toolkit. Employing welded wire mesh netting means investing in a future-proof solution designed to meet the demands of today's fast-paced world while promising sustainability for the years to come.

Technical specifications underscore the expertise behind welded wire mesh netting. High-quality materials, such as stainless steel or galvanized carbon steel, are selected to endure environmental stressors. Moreover, specialized coatings can be applied to extend its lifespan and expand its utility across multiple domains. A material scientist elaborated on advanced manufacturing techniques that refine these meshes for particular purposes, highlighting the ongoing innovation within the industry. Welded wire mesh netting is also heavily regulated, cementing its authority in sectors where compliance with safety and quality standards is non-negotiable. Certifications from reputable standard organizations ensure that the products meet specific load-bearing and durability benchmarks. Engineers and project managers can reference these standards to make informed decisions regarding their applications, further instilling confidence in their projects' success. Trustworthiness is inherent in its simplicity and functionality. It requires minimal maintenance and boasts a lifecycle that outlasts many alternative materials. Customers have expressed satisfaction due to its consistent performance and the peace of mind it offers when used in critical applications. Suppliers with a proven track record often provide warranties, further cementing consumer trust. In conclusion, welded wire mesh netting stands as a testament to modern innovation and reliability. It bridges gap between various fields, offering practical, efficient, and reliable solutions. Its role in reinforcing structures, protecting agricultural investments, and ensuring industrial safety cannot be understated. Experts in each respective domain rely on its dependability, cementing its status as an irreplaceable component in their professional toolkit. Employing welded wire mesh netting means investing in a future-proof solution designed to meet the demands of today's fast-paced world while promising sustainability for the years to come.

Pervious:

Next:

Latest news

-

Why a Chain Link Fence is the Right Choice

NewsJul.09,2025

-

Upgrade Your Fencing with High-Quality Coated Chicken Wire

NewsJul.09,2025

-

The Power of Fence Post Spikes

NewsJul.09,2025

-

The Best Pet Enclosures for Every Need

NewsJul.09,2025

-

Secure Your Property with Premium Barbed Wire Solutions

NewsJul.09,2025

-

Enhance Your Construction Projects with Quality Gabion Boxes

NewsJul.09,2025

Products categories

NEED HELP?

Don' t Hesitate To Contact Us For More Information About Company Or Service

CONTACT US