Feb . 13, 2025 08:27 Back to list

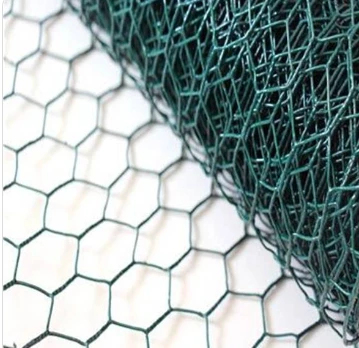

PVC Coating welded wire netting

Welded wire gauge 16, a staple in both commercial and residential construction, presents numerous applications that necessitate a deep dive into its properties and benefits. This gauge size, known for its ideal balance between strength and flexibility, offers unique advantages that cater to various needs in the construction and manufacturing industries.

Beyond these technical aspects, sustainable practices in the manufacturing of 16-gauge welded wire have also seen significant advancements. Many manufacturers now opt for recycled materials in the production process, reducing the environmental impact. Furthermore, advances in coating technologies ensure that these wires not only last longer but also do less harm to the environment. This eco-friendly approach appeals to the modern consumer base that is growing increasingly conscious of environmental issues. Considering the future direction of construction technologies, 16-gauge welded wire shows promise in incorporating smart technology. With the advent of IoT, integrating sensor technologies into construction materials could provide real-time data on structural integrity and environmental conditions. This innovation would allow for proactive maintenance and longer lifespan of infrastructures. For product selection, discerning consumers should evaluate various sources and manufacturers. It’s important that buyers look for suppliers with clear documentation of their compliance with industry standards, as well as a proven track record of quality. Additionally, seeking recommendations and reviews by industry professionals can provide invaluable insights into performance expectations. In conclusion, the 16-gauge welded wire continues to be a pivotal material in construction, offering a balance of strength, flexibility, and durability. Professionals and hobbyists alike can leverage its properties for a variety of applications, supported by standards that ensure top-notch quality. With its trusted performance and potential for technological advancement, 16-gauge welded wire remains a reliable choice for future projects, accentuating eco-friendly and sustainable construction methods.

Beyond these technical aspects, sustainable practices in the manufacturing of 16-gauge welded wire have also seen significant advancements. Many manufacturers now opt for recycled materials in the production process, reducing the environmental impact. Furthermore, advances in coating technologies ensure that these wires not only last longer but also do less harm to the environment. This eco-friendly approach appeals to the modern consumer base that is growing increasingly conscious of environmental issues. Considering the future direction of construction technologies, 16-gauge welded wire shows promise in incorporating smart technology. With the advent of IoT, integrating sensor technologies into construction materials could provide real-time data on structural integrity and environmental conditions. This innovation would allow for proactive maintenance and longer lifespan of infrastructures. For product selection, discerning consumers should evaluate various sources and manufacturers. It’s important that buyers look for suppliers with clear documentation of their compliance with industry standards, as well as a proven track record of quality. Additionally, seeking recommendations and reviews by industry professionals can provide invaluable insights into performance expectations. In conclusion, the 16-gauge welded wire continues to be a pivotal material in construction, offering a balance of strength, flexibility, and durability. Professionals and hobbyists alike can leverage its properties for a variety of applications, supported by standards that ensure top-notch quality. With its trusted performance and potential for technological advancement, 16-gauge welded wire remains a reliable choice for future projects, accentuating eco-friendly and sustainable construction methods.

Pervious:

Latest news

-

Why a Chain Link Fence is the Right Choice

NewsJul.09,2025

-

Upgrade Your Fencing with High-Quality Coated Chicken Wire

NewsJul.09,2025

-

The Power of Fence Post Spikes

NewsJul.09,2025

-

The Best Pet Enclosures for Every Need

NewsJul.09,2025

-

Secure Your Property with Premium Barbed Wire Solutions

NewsJul.09,2025

-

Enhance Your Construction Projects with Quality Gabion Boxes

NewsJul.09,2025

Products categories

NEED HELP?

Don' t Hesitate To Contact Us For More Information About Company Or Service

CONTACT US