Feb . 13, 2025 16:54 Back to list

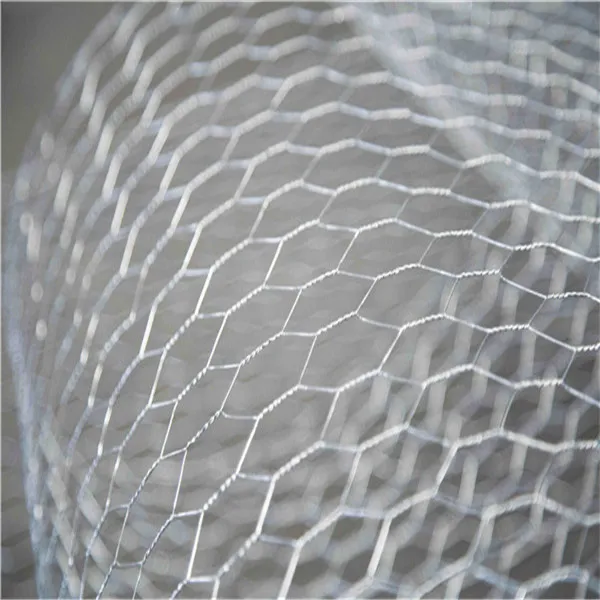

PVC Coating welded wire netting

Welded wire fabric reinforcement, often overlooked in traditional construction methods, presents an evolving landscape that is proving transformative for diverse building projects. The effectiveness and efficiency across residential, commercial, and infrastructure development are becoming increasingly acknowledged. Its role is critical for reinforcing concrete structures, offering numerous benefits that enhance overall structural integrity and project economy.

Case studies reflect the tangible benefits when welded wire fabric is incorporated into construction projects. For instance, urban infrastructural developments have demonstrated improved performance and extended lifespan, addressing common issues such as cracking and surface wear. The resistance against environmental factors such as moisture and temperature variations enhances the protective qualities of the concrete, resulting in structures that require less maintenance and have a lower lifecycle cost. In terms of expertise, engineers and construction professionals recognize the crucial role of proper installation practices. The unique grid patterns of welded wire fabric require attention to detail during placement to ensure optimal performance. Experienced teams capable of leveraging these installation techniques can maximize the benefits and uphold the structural integrity that welded wire fabric is designed to provide. The authoritative value of welded wire fabric is further bolstered by ongoing research and development. Innovations in manufacturing processes continue to enhance material strength and application versatility. The industry’s commitment to improving this technology reflects a broader understanding of future construction needs, further establishing welded wire fabric as a mainstay in modern reinforcement solutions. Trust in welded wire fabric is rooted in its track record and backing by industry standards. The confluence of past performances in extensive projects and the backing by certified structural standards makes this material a dependable choice. For project managers and engineers, the confidence bestowed by choosing a proven reinforcement method is invaluable, allowing them to anticipate fewer structural issues and better predict project longevity. In conclusion, welded wire fabric reinforcement stands as a compelling option for those invested in forward-thinking construction strategies. Its comprehensive advantages, ranging from economic to environmental, present this as a versatile and effective reinforcement solution. With a growing body of knowledge and refinement in application methods, welded wire fabric is not merely an asset but a pivotal element for shaping resilient, sustainable infrastructure for the future.

Case studies reflect the tangible benefits when welded wire fabric is incorporated into construction projects. For instance, urban infrastructural developments have demonstrated improved performance and extended lifespan, addressing common issues such as cracking and surface wear. The resistance against environmental factors such as moisture and temperature variations enhances the protective qualities of the concrete, resulting in structures that require less maintenance and have a lower lifecycle cost. In terms of expertise, engineers and construction professionals recognize the crucial role of proper installation practices. The unique grid patterns of welded wire fabric require attention to detail during placement to ensure optimal performance. Experienced teams capable of leveraging these installation techniques can maximize the benefits and uphold the structural integrity that welded wire fabric is designed to provide. The authoritative value of welded wire fabric is further bolstered by ongoing research and development. Innovations in manufacturing processes continue to enhance material strength and application versatility. The industry’s commitment to improving this technology reflects a broader understanding of future construction needs, further establishing welded wire fabric as a mainstay in modern reinforcement solutions. Trust in welded wire fabric is rooted in its track record and backing by industry standards. The confluence of past performances in extensive projects and the backing by certified structural standards makes this material a dependable choice. For project managers and engineers, the confidence bestowed by choosing a proven reinforcement method is invaluable, allowing them to anticipate fewer structural issues and better predict project longevity. In conclusion, welded wire fabric reinforcement stands as a compelling option for those invested in forward-thinking construction strategies. Its comprehensive advantages, ranging from economic to environmental, present this as a versatile and effective reinforcement solution. With a growing body of knowledge and refinement in application methods, welded wire fabric is not merely an asset but a pivotal element for shaping resilient, sustainable infrastructure for the future.

Pervious:

Latest news

-

Why a Chain Link Fence is the Right Choice

NewsJul.09,2025

-

Upgrade Your Fencing with High-Quality Coated Chicken Wire

NewsJul.09,2025

-

The Power of Fence Post Spikes

NewsJul.09,2025

-

The Best Pet Enclosures for Every Need

NewsJul.09,2025

-

Secure Your Property with Premium Barbed Wire Solutions

NewsJul.09,2025

-

Enhance Your Construction Projects with Quality Gabion Boxes

NewsJul.09,2025

Products categories

NEED HELP?

Don' t Hesitate To Contact Us For More Information About Company Or Service

CONTACT US