Feb . 13, 2025 05:52 Back to list

PVC Coating welded wire netting

The versatility and durability of welded wire have established it as an indispensable material in a variety of applications, from construction to gardening. Among the different specifications, the 16 gauge welded wire stands out for its balance of strength, flexibility, and affordability. Understanding its properties and potential uses can guide both professional and amateur projects to successful outcomes.

Further, the aesthetic and functional qualities of 16 gauge welded wire open doors for innovative architectural designs. It has found its place in modern architectural projects as a complement to glass and wood, adding a layer of security without compromising aesthetic value. Designers favor it for its ability to blend into different settings while maintaining a sleek appearance. The thinness of 16 gauge wire can create unobtrusive partitions in indoor spaces or subtle boundary markings in open areas like gardens or recreational zones. The importance of understanding and choosing the right material cannot be overstated, particularly with the 16 gauge welded wire, as it addresses both practical needs and stylistic choices. For project managers, builders, and DIY enthusiasts, its user-friendly nature encourages experimentation, adaptability, and effective problem-solving across various applications. Its benefits are not just limited to its physical attributes; the cost-effectiveness of 16 gauge wire also positions it as an economically viable solution for quality demand. Despite its advantages, proper handling and installation of 16 gauge welded wire cannot be ignored to ensure long-lasting functionality. Experts recommend securing the wire with appropriate fastenings and ensuring tension across its spans to prevent sagging or distortion. Precision in installation reflects directly on performance, making attention to detail and adherence to best practices essential in achieving desired results. In conclusion, 16 gauge welded wire serves as a testament to how material science and practical application merge within industrial, agricultural, and creative endeavors. Balancing flexibility, durability, and cost-effectiveness, it empowers users to innovate while maintaining reliability. For those venturing into new projects requiring durable wire solutions, the 16 gauge option warrants serious consideration, offering tried and tested quality alongside a realm of potential that can transform any ordinary project into an extraordinary accomplishment. Such materials underline the continuous evolution in construction and design, fueled by the desire to build safer, more efficient, and aesthetically pleasing spaces.

Further, the aesthetic and functional qualities of 16 gauge welded wire open doors for innovative architectural designs. It has found its place in modern architectural projects as a complement to glass and wood, adding a layer of security without compromising aesthetic value. Designers favor it for its ability to blend into different settings while maintaining a sleek appearance. The thinness of 16 gauge wire can create unobtrusive partitions in indoor spaces or subtle boundary markings in open areas like gardens or recreational zones. The importance of understanding and choosing the right material cannot be overstated, particularly with the 16 gauge welded wire, as it addresses both practical needs and stylistic choices. For project managers, builders, and DIY enthusiasts, its user-friendly nature encourages experimentation, adaptability, and effective problem-solving across various applications. Its benefits are not just limited to its physical attributes; the cost-effectiveness of 16 gauge wire also positions it as an economically viable solution for quality demand. Despite its advantages, proper handling and installation of 16 gauge welded wire cannot be ignored to ensure long-lasting functionality. Experts recommend securing the wire with appropriate fastenings and ensuring tension across its spans to prevent sagging or distortion. Precision in installation reflects directly on performance, making attention to detail and adherence to best practices essential in achieving desired results. In conclusion, 16 gauge welded wire serves as a testament to how material science and practical application merge within industrial, agricultural, and creative endeavors. Balancing flexibility, durability, and cost-effectiveness, it empowers users to innovate while maintaining reliability. For those venturing into new projects requiring durable wire solutions, the 16 gauge option warrants serious consideration, offering tried and tested quality alongside a realm of potential that can transform any ordinary project into an extraordinary accomplishment. Such materials underline the continuous evolution in construction and design, fueled by the desire to build safer, more efficient, and aesthetically pleasing spaces.

Pervious:

Latest news

-

Why a Chain Link Fence is the Right Choice

NewsJul.09,2025

-

Upgrade Your Fencing with High-Quality Coated Chicken Wire

NewsJul.09,2025

-

The Power of Fence Post Spikes

NewsJul.09,2025

-

The Best Pet Enclosures for Every Need

NewsJul.09,2025

-

Secure Your Property with Premium Barbed Wire Solutions

NewsJul.09,2025

-

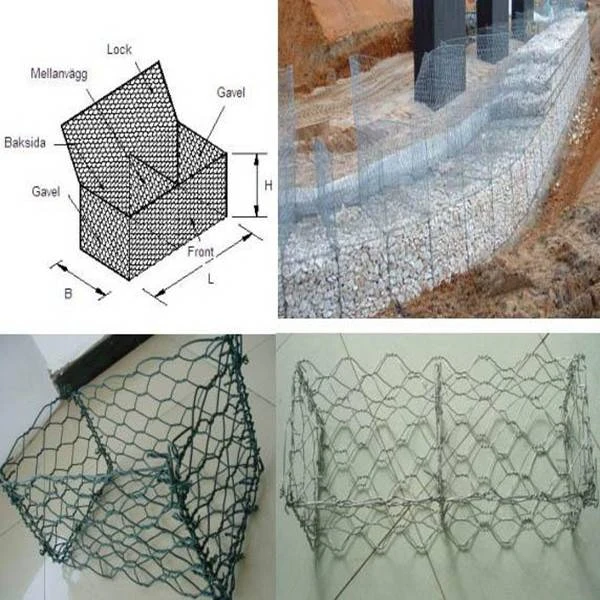

Enhance Your Construction Projects with Quality Gabion Boxes

NewsJul.09,2025

Products categories

NEED HELP?

Don' t Hesitate To Contact Us For More Information About Company Or Service

CONTACT US