Nov . 07, 2024 16:38 Back to list

Welded Reinforcement Mesh Solutions for Enhanced Concrete Strength and Durability

Understanding Welded Reinforcement Mesh for Concrete

Welded reinforcement mesh, often referred to as welded wire fabric (WWF), has become an integral component in modern concrete construction. This material is essential for enhancing the strength, durability, and overall performance of concrete structures. In this article, we will delve into what welded reinforcement mesh is, its benefits, applications, and installation techniques, providing a comprehensive overview of its role in concrete reinforcement.

What is Welded Reinforcement Mesh?

Welded reinforcement mesh is a series of crossed steel wires that are welded together at their intersections. This mesh is produced in various sizes and diameters, allowing it to meet diverse structural requirements. Typically made of high-quality carbon steel, welded reinforcement mesh is precisely constructed to ensure consistency in spacing and placement, which is crucial for maintaining the structural integrity of concrete.

The mesh is available in different patterns and configurations, commonly identified by the spacing of the wires and the wire diameter. For example, a mesh labeled 6x6 W2.1xW2.1 indicates a grid of 6 inches by 6 inches with wire diameters of 0.21 inches. This standardization of dimensions not only simplifies the selection process but also helps in achieving uniform concrete reinforcement across various construction projects.

Benefits of Welded Reinforcement Mesh

1. Enhanced Strength One of the primary benefits of welded reinforcement mesh is its ability to significantly increase the tensile strength of concrete. Concrete is predominantly strong in compression but weak in tension. By incorporating welded mesh, engineers can mitigate the risk of cracks and improve the overall tensile capacity of structures.

2. Improved Durability Structures reinforced with welded mesh exhibit greater resistance to environmental stresses such as temperature fluctuations, moisture, and corrosive elements. This durability translates to longer service life and reduced maintenance costs over time.

3. Workability and Efficiency Compared to traditional rebar, welded mesh is easier to handle and install. It can cover large areas with fewer pieces, reducing the labor required for installation. This efficiency can lead to faster construction timelines and lower overall project costs.

4. Cost-Effectiveness While there might be a perception that welded reinforcement mesh comes at a premium, it often proves to be more economical in the long run. Its durability and reduced maintenance needs can offset the initial investment, while its ease of installation helps in saving labor costs.

welded reinforcement mesh for concrete

5. Versatility Welded reinforcement mesh is adaptable for various applications. From slab foundations and pavements to walls and precast concrete elements, this material is suitable for a wide range of construction projects, including residential, commercial, and industrial structures.

Applications of Welded Reinforcement Mesh

Welded reinforcement mesh is utilized in various concrete applications

- Floors and Pavements It is commonly used in concrete slabs for residential and commercial buildings, driveways, and parking lots to prevent cracking and provide uniform load distribution. - Walls When included in masonry or precast walls, welded mesh helps enhance structural integrity and resistance to lateral forces. - Bridges and Overpasses In bridge construction, the mesh reinforces concrete components that endure significant loads and stresses. - Retaining Walls The use of welded mesh in retaining walls ensures stability and prevents soil erosion.

Installation Techniques

Installing welded reinforcement mesh requires careful planning and execution. The following steps are typically recommended

1. Site Preparation The area must be cleared of debris and graded to ensure proper drainage. 2. Placement The mesh is laid flat on the prepared surface, ensuring it is positioned according to project specifications. The mesh can be supported by chairs or spacers to maintain the correct cover over the rebar. 3. Concrete Pouring Once the mesh is securely positioned, concrete is poured over it. Proper placement of the concrete helps to envelop the mesh entirely, ensuring effective bonding. 4. Finishing After pouring, finishing techniques such as leveling and troweling may be employed to achieve the desired surface finish.

Conclusion

Welded reinforcement mesh plays a crucial role in modern concrete construction by enhancing strength, durability, and cost-effectiveness. As the demand for resilient structures continues to grow, understanding the benefits and applications of this material is essential for engineers, architects, and builders alike. Its versatility and efficiency make welded reinforcement mesh a preferred choice in various construction projects, paving the way for safer and more reliable infrastructure.

-

Why a Chain Link Fence is the Right Choice

NewsJul.09,2025

-

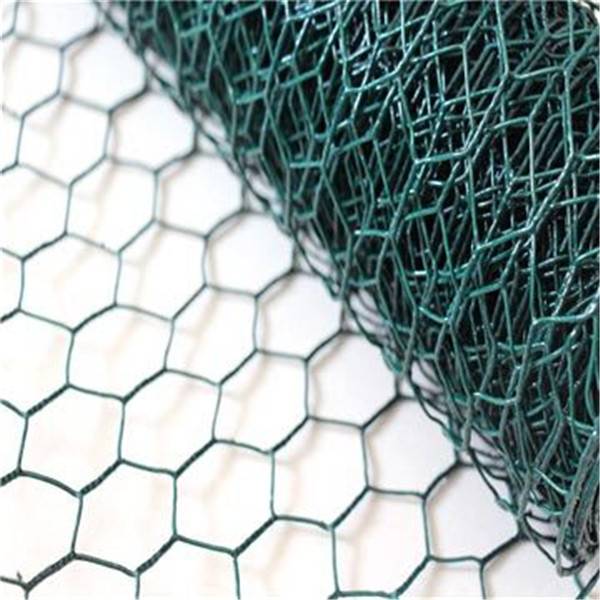

Upgrade Your Fencing with High-Quality Coated Chicken Wire

NewsJul.09,2025

-

The Power of Fence Post Spikes

NewsJul.09,2025

-

The Best Pet Enclosures for Every Need

NewsJul.09,2025

-

Secure Your Property with Premium Barbed Wire Solutions

NewsJul.09,2025

-

Enhance Your Construction Projects with Quality Gabion Boxes

NewsJul.09,2025

Products categories