Feb . 13, 2025 03:52 Back to list

PVC Coating welded wire netting

Welded mesh 25x25, an indispensable material in construction and various industrial applications, stands out for its reliability and multifaceted uses. This particular mesh size is gaining popularity among seasoned professionals and construction enthusiasts due to its optimal balance between strength and flexibility. Let's delve into why welded mesh 25x25 is becoming a staple in modern development projects and how it meets the rigorous demands of today's building standards.

Authority is established through the mesh’s compliance with international building codes and standards. Certification from recognized bodies provides peace of mind to contractors and stakeholders who must adhere to stringent safety regulations. The assurance that welded mesh 25x25 can withstand various stress tests without failure solidifies its standing as a trusted material in construction. Trustworthiness, combined with these factors, underscores the material’s reputation in the market. Feedback from construction managers who have utilized this mesh points to its consistent quality and performance, often citing reduced material waste and improved structural integrity as key benefits. Additionally, suppliers of welded mesh 25x25 often offer detailed documentation, including test results and technical support, which further augments their credibility and reassures buyers of their investment's value. In summary, the welded mesh 25x25 is not merely a construction component; it is a critical element that complements modern building techniques. It offers a blend of strength, ease of installation, and durability that few other materials can match. For professionals seeking a reliable material that embodies expertise, authority, and trustworthiness, welded mesh 25x25 is a compelling choice that aligns with both contemporary engineering demands and future construction challenges.

Authority is established through the mesh’s compliance with international building codes and standards. Certification from recognized bodies provides peace of mind to contractors and stakeholders who must adhere to stringent safety regulations. The assurance that welded mesh 25x25 can withstand various stress tests without failure solidifies its standing as a trusted material in construction. Trustworthiness, combined with these factors, underscores the material’s reputation in the market. Feedback from construction managers who have utilized this mesh points to its consistent quality and performance, often citing reduced material waste and improved structural integrity as key benefits. Additionally, suppliers of welded mesh 25x25 often offer detailed documentation, including test results and technical support, which further augments their credibility and reassures buyers of their investment's value. In summary, the welded mesh 25x25 is not merely a construction component; it is a critical element that complements modern building techniques. It offers a blend of strength, ease of installation, and durability that few other materials can match. For professionals seeking a reliable material that embodies expertise, authority, and trustworthiness, welded mesh 25x25 is a compelling choice that aligns with both contemporary engineering demands and future construction challenges.

Pervious:

Latest news

-

Why a Chain Link Fence is the Right Choice

NewsJul.09,2025

-

Upgrade Your Fencing with High-Quality Coated Chicken Wire

NewsJul.09,2025

-

The Power of Fence Post Spikes

NewsJul.09,2025

-

The Best Pet Enclosures for Every Need

NewsJul.09,2025

-

Secure Your Property with Premium Barbed Wire Solutions

NewsJul.09,2025

-

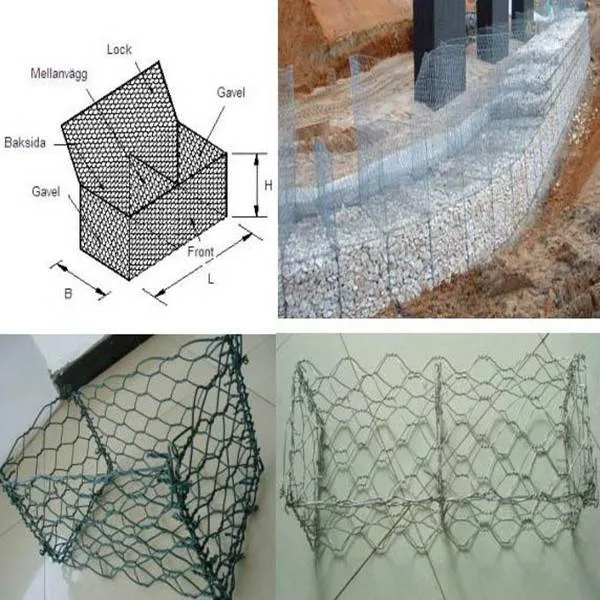

Enhance Your Construction Projects with Quality Gabion Boxes

NewsJul.09,2025

Products categories

NEED HELP?

Don' t Hesitate To Contact Us For More Information About Company Or Service

CONTACT US