Sep . 16, 2024 08:00 Back to list

welded wire mesh sizes for concrete

Understanding Welded Wire Mesh Sizes for Concrete

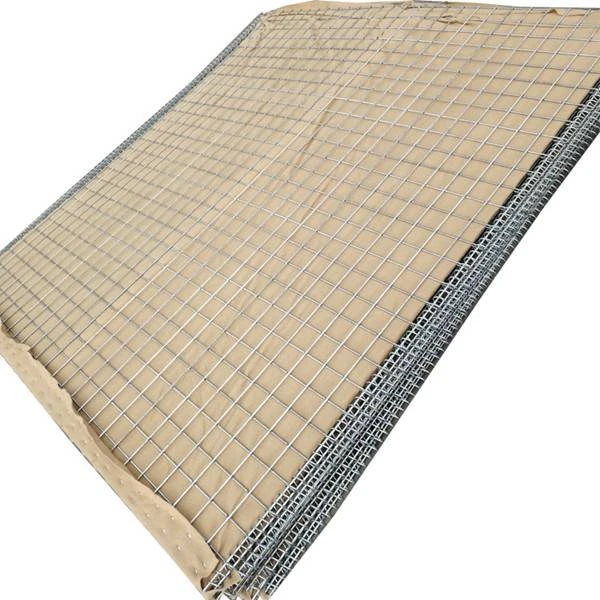

Welded wire mesh, commonly referred to as reinforcement mesh, is an integral component in concrete construction. It consists of a grid of steel wires that are welded together at various intervals, forming a robust structure that helps distribute loads and prevent cracking in concrete slabs, beams, and walls. Understanding the different sizes of welded wire mesh is crucial for engineers, contractors, and builders to ensure they select the right type for their specific projects.

Sizes and Specifications

Welded wire mesh is available in various sizes, with specifications typically based on two main factors the diameter of the wire and the spacing between the wires. The most common wire diameters range from 10 gauge (approximately 0.135 inches) to 6 gauge (approximately 0.162 inches). The spacing of the wires can vary significantly, generally measuring anywhere from 2 inches to 12 inches apart.

For example, a popular size for residential applications is W2.0/W2.0, which denotes that the wires are 2.0 mm in diameter, spaced 6 inches apart. This type of mesh is often used in thin slabs, driveways, and patio applications where moderate strength is sufficient. On the other hand, W4.0/W4.0 with a greater diameter may be chosen for heavier loads like industrial floors or foundations.

Benefits of Different Sizes

Selecting the appropriate size of welded wire mesh offers several benefits. Mesh with smaller wire diameter and tighter spacing is ideal for controlling crack width in thin slabs, providing enhanced durability. Conversely, larger diameter wires with wider spacing are more suited for heavy-duty applications where structural integrity is critical.

The choice of mesh size also depends on the specific load requirements, environmental conditions, and the type of concrete mix being used

. For example, using thicker mesh in high-traffic areas can significantly enhance the lifespan of the concrete, reducing the need for repairs and maintenance over time.welded wire mesh sizes for concrete

Applications of Welded Wire Mesh

Welded wire mesh is versatile and can be utilized in various applications. In residential construction, it is commonly used in floor slabs, driveways, and sidewalks to ensure a stable, crack-resistant surface. In commercial and industrial settings, it reinforces pavements, warehouses, and manufacturing facilities, where heavy machinery and equipment exert substantial stress on the concrete.

In addition to load-bearing applications, welded wire mesh can also be employed in fencing, play areas, and concrete precast products. This versatility stems from its ability to be customized to meet different strength requirements and project demands.

Installation Considerations

When installing welded wire mesh, it's essential to position it correctly within the concrete slab. It should ideally be placed toward the middle of the slab thickness to maximize its effectiveness in tensile strength reinforcement. Furthermore, ensuring proper overlap of mesh sheets and securing them adequately will prevent movement during the pouring process.

Conclusion

In conclusion, understanding welded wire mesh sizes is crucial for ensuring the strength and durability of concrete structures. By carefully selecting the appropriate mesh size and type based on the specific requirements of a project, builders can enhance the performance of concrete, reduce cracking, and extend the lifespan of constructions. Ultimately, the right choice in welded wire mesh leads to safer and more reliable structures.

-

Why a Chain Link Fence is the Right Choice

NewsJul.09,2025

-

Upgrade Your Fencing with High-Quality Coated Chicken Wire

NewsJul.09,2025

-

The Power of Fence Post Spikes

NewsJul.09,2025

-

The Best Pet Enclosures for Every Need

NewsJul.09,2025

-

Secure Your Property with Premium Barbed Wire Solutions

NewsJul.09,2025

-

Enhance Your Construction Projects with Quality Gabion Boxes

NewsJul.09,2025

Products categories