Sep . 04, 2024 21:16 Back to list

welded fabric reinforcement

Welded Fabric Reinforcement An Overview

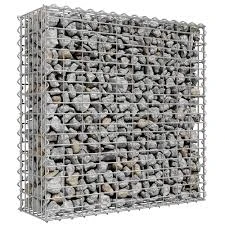

Welded fabric reinforcement, often referred to as welded wire mesh, is a vital component in modern construction and civil engineering. This innovative material consists of interconnected steel wires that are welded together at regular intervals, forming a grid-like structure. It is widely used to enhance the strength and durability of concrete structures, making it an indispensable part of reinforcement techniques.

One of the primary advantages of welded fabric reinforcement is its uniform tensile strength. The precise manufacturing process ensures that each section of the mesh has consistent mechanical properties, resulting in predictable behavior when subjected to loads. This consistency is crucial in ensuring the integrity of structures, particularly in high-stress environments such as bridges, high-rise buildings, and industrial facilities.

Additionally, the use of welded wire mesh simplifies the construction process. Unlike traditional reinforcement methods that require individual bars to be cut and tied, welded fabric can be pre-fabricated to desired shapes and sizes, allowing for quick and efficient installation. This not only saves time on-site but also reduces labor costs, making it an economically viable option for large projects.

welded fabric reinforcement

Another notable feature of welded fabric reinforcement is its versatility. It can be used in a variety of applications, including slabs, walls, pavements, and precast elements. The mesh can also be customized based on specific project requirements, with variations in wire diameter, spacing, and material properties. This adaptability makes it suitable for both residential and commercial projects.

Welded fabric reinforcement also contributes to the sustainability of construction practices. By utilizing steel, a recyclable material, in its production, the environmental impact of construction can be significantly reduced. Furthermore, the improved durability of structures reinforced with welded mesh leads to longer service lives, minimizing the need for repairs and replacements over time.

While the benefits of welded fabric reinforcement are numerous, it is essential to ensure proper design and installation practices. Engineers must carefully consider factors such as load distribution, environmental conditions, and concrete cover to optimize the performance of the reinforcement. When executed correctly, welded fabric reinforcement can significantly enhance the longevity and safety of concrete structures.

In conclusion, welded fabric reinforcement plays a crucial role in contemporary construction. Its strength, efficiency, versatility, and sustainability make it an ideal choice for a range of applications. As the industry continues to evolve, advancements in welded mesh technology are likely to further improve its performance and applicability, solidifying its position as a key element in modern structural engineering.

-

build-a-discreet-chicken-run-with-sturdy-green-coated-chicken-wire

NewsAug.23,2025

-

a-guide-to-selecting-the-most-durable-field-gates-for-your-property

NewsAug.23,2025

-

green-mesh-fencing-rolls-offer-versatile-solutions-for-diverse-needs

NewsAug.23,2025

-

chain-fence-for-durable-and-versatile-enclosure-solutions

NewsAug.23,2025

-

garden-edging-fence-for-functional-and-decorative-landscaping

NewsAug.23,2025

-

3d-wire-mesh-fence-for-versatile-security-and-decoration

NewsAug.23,2025

Products categories