Jan . 20, 2025 08:09 Back to list

types of brc wire mesh

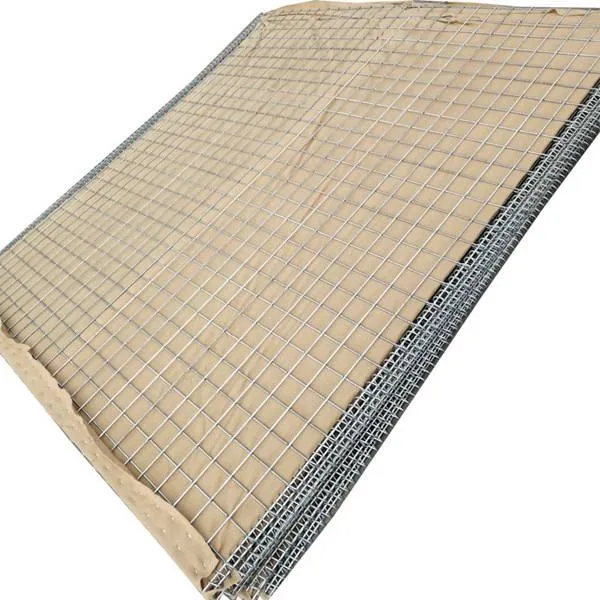

When it comes to the essential building blocks of construction and infrastructure development, BRC wire mesh stands out due to its versatility, strength, and reliability. It is essential for architects, civil engineers, and construction professionals to understand the different types of BRC wire mesh available to ensure that they are using the most appropriate material for their projects. This article dives into the specifics, providing expertise, experience, and authoritative knowledge about the various types of BRC wire mesh and their applications, building trust with industry professionals seeking comprehensive information.

High tensile wire mesh, another variant, is engineered to withstand greater forces, making it ideal for heavy-duty applications such as highway construction or industrial floor slabs. The wires in this mesh type are tensioned before welding, which bolsters the overall strength of the sheet. It meets the requirements of demanding engineering loads and offers enhanced support without compromising on flexibility. BRC wire mesh can also be custom-made to meet specific project needs. Customization includes altering wire diameter, mesh aperture size, and sheet size to suit unique requirements. This level of adaptability is crucial for special projects that do not fit into the conventional parameters, allowing engineers and architects to design without compromise. Expertise in choosing the right type of BRC wire mesh involves understanding the project environment, the expected load and stress factors, and any aesthetic considerations. This requires a comprehensive assessment of the project site and an understanding of the physical characteristics of each wire mesh type. In terms of authoritativeness, manufacturers of BRC wire mesh often provide data sheets and test results that confirm compliance with industry standards such as BS, ASTM, or ISO guidelines. Engaging with trusted suppliers who offer certified products ensures the mesh used meets the necessary safety and quality standards, which is crucial for maintaining the integrity of the project. In conclusion, the various types of BRC wire mesh are pivotal in the construction industry, each serving specific roles tailored to different environmental and structural needs. Whether it is the ubiquitous welded mesh for general applications, the corrosion-resistant galvanized or stainless steel options, or the robust high tensile variety, understanding these distinctions ensures that construction professionals can choose the right material for robust and lasting infrastructure. Trust is built by aligning with standard-compliant materials and expert advice, ensuring that any construction project stands the test of time and environmental challenges.

High tensile wire mesh, another variant, is engineered to withstand greater forces, making it ideal for heavy-duty applications such as highway construction or industrial floor slabs. The wires in this mesh type are tensioned before welding, which bolsters the overall strength of the sheet. It meets the requirements of demanding engineering loads and offers enhanced support without compromising on flexibility. BRC wire mesh can also be custom-made to meet specific project needs. Customization includes altering wire diameter, mesh aperture size, and sheet size to suit unique requirements. This level of adaptability is crucial for special projects that do not fit into the conventional parameters, allowing engineers and architects to design without compromise. Expertise in choosing the right type of BRC wire mesh involves understanding the project environment, the expected load and stress factors, and any aesthetic considerations. This requires a comprehensive assessment of the project site and an understanding of the physical characteristics of each wire mesh type. In terms of authoritativeness, manufacturers of BRC wire mesh often provide data sheets and test results that confirm compliance with industry standards such as BS, ASTM, or ISO guidelines. Engaging with trusted suppliers who offer certified products ensures the mesh used meets the necessary safety and quality standards, which is crucial for maintaining the integrity of the project. In conclusion, the various types of BRC wire mesh are pivotal in the construction industry, each serving specific roles tailored to different environmental and structural needs. Whether it is the ubiquitous welded mesh for general applications, the corrosion-resistant galvanized or stainless steel options, or the robust high tensile variety, understanding these distinctions ensures that construction professionals can choose the right material for robust and lasting infrastructure. Trust is built by aligning with standard-compliant materials and expert advice, ensuring that any construction project stands the test of time and environmental challenges.

Pervious:

Next:

Latest news

-

Why a Chain Link Fence is the Right Choice

NewsJul.09,2025

-

Upgrade Your Fencing with High-Quality Coated Chicken Wire

NewsJul.09,2025

-

The Power of Fence Post Spikes

NewsJul.09,2025

-

The Best Pet Enclosures for Every Need

NewsJul.09,2025

-

Secure Your Property with Premium Barbed Wire Solutions

NewsJul.09,2025

-

Enhance Your Construction Projects with Quality Gabion Boxes

NewsJul.09,2025

Products categories

NEED HELP?

Don' t Hesitate To Contact Us For More Information About Company Or Service

CONTACT US