Jan . 20, 2025 07:39 Back to list

type of brc mesh

BRC mesh, a staple in the construction and engineering sectors, represents a versatile solution with applications ranging from reinforcing concrete structures to enhancing security systems. As a prominent product in these domains, understanding the different types of BRC mesh available is crucial for industry professionals seeking optimal results.

Choosing the right type of BRC mesh involves weighing factors such as environmental conditions, structural requirements, and project budgets. Corrosion resistance, for example, is a critical consideration for projects exposed to moisture or chemicals. In such cases, galvanized or PVC-coated meshes are preferable to ensure extended lifespan and reduced maintenance costs. Furthermore, the choice of wire diameter and mesh spacing directly impacts the structural integrity and cost. Thicker wires and smaller mesh spaces provide higher tensile strength, suitable for heavy-duty applications like infrastructure projects. Conversely, lighter gauges and larger spaces suffice for decorative and non-load-bearing purposes. In embracing the world of BRC mesh, professionals are encouraged to engage with industry experts and suppliers to obtain comprehensive insights tailored to specific project needs. Knowledge of the latest advancements and innovations in BRC mesh technology can unveil new possibilities and efficiencies in construction methodologies. In conclusion, understanding and selecting the appropriate type of BRC mesh can significantly enhance the efficiency and effectiveness of construction projects. The right choice not only ensures structural integrity and longevity but also optimizes resources and budgets. With ongoing advancements in material science, the future of BRC mesh promises even greater opportunities and innovations, solidifying its place as a cornerstone in the construction and engineering industry.

Choosing the right type of BRC mesh involves weighing factors such as environmental conditions, structural requirements, and project budgets. Corrosion resistance, for example, is a critical consideration for projects exposed to moisture or chemicals. In such cases, galvanized or PVC-coated meshes are preferable to ensure extended lifespan and reduced maintenance costs. Furthermore, the choice of wire diameter and mesh spacing directly impacts the structural integrity and cost. Thicker wires and smaller mesh spaces provide higher tensile strength, suitable for heavy-duty applications like infrastructure projects. Conversely, lighter gauges and larger spaces suffice for decorative and non-load-bearing purposes. In embracing the world of BRC mesh, professionals are encouraged to engage with industry experts and suppliers to obtain comprehensive insights tailored to specific project needs. Knowledge of the latest advancements and innovations in BRC mesh technology can unveil new possibilities and efficiencies in construction methodologies. In conclusion, understanding and selecting the appropriate type of BRC mesh can significantly enhance the efficiency and effectiveness of construction projects. The right choice not only ensures structural integrity and longevity but also optimizes resources and budgets. With ongoing advancements in material science, the future of BRC mesh promises even greater opportunities and innovations, solidifying its place as a cornerstone in the construction and engineering industry.

Pervious:

Latest news

-

Why a Chain Link Fence is the Right Choice

NewsJul.09,2025

-

Upgrade Your Fencing with High-Quality Coated Chicken Wire

NewsJul.09,2025

-

The Power of Fence Post Spikes

NewsJul.09,2025

-

The Best Pet Enclosures for Every Need

NewsJul.09,2025

-

Secure Your Property with Premium Barbed Wire Solutions

NewsJul.09,2025

-

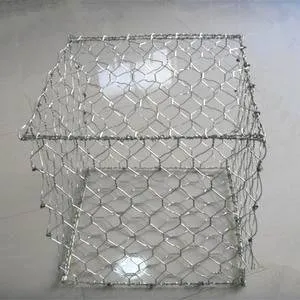

Enhance Your Construction Projects with Quality Gabion Boxes

NewsJul.09,2025

Products categories

NEED HELP?

Don' t Hesitate To Contact Us For More Information About Company Or Service

CONTACT US