Sep . 12, 2025 10:20 Back to list

Strong Welded Mesh Gabions: Easy Install & Durable Solutions

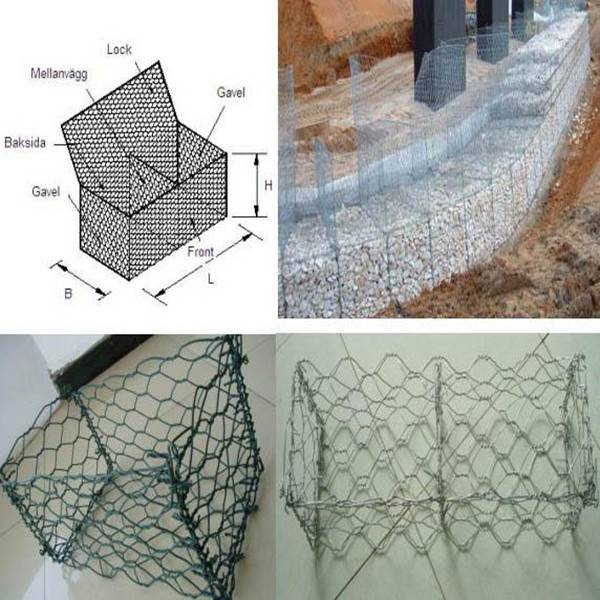

Introduction to welded mesh gabion Systems

In civil engineering and landscape architecture, the demand for robust, environmentally sound, and aesthetically pleasing retaining structures is ever-growing. Among the most innovative solutions, the welded mesh gabion stands out as a superior choice. These modular units, constructed from rigid, electrically welded wire mesh panels, are engineered to be filled with natural stone, gravel, or recycled concrete. This creates permeable, flexible, and monolithic structures capable of effectively managing erosion, stabilizing slopes, and forming architectural elements.

Unlike traditional methods, welded mesh gabion systems offer a unique combination of structural integrity, environmental compatibility, and long-term cost-effectiveness. Their design facilitates efficient water drainage, minimizing hydrostatic pressure and preventing damage from freeze-thaw cycles. This makes them indispensable in critical infrastructure projects, from highway embankment protection to complex hydraulic engineering applications.

Industry Trends and Market Dynamics

The global market for gabion solutions, particularly those involving welded mesh gabion baskets, is experiencing substantial growth driven by increased infrastructure spending, a heightened focus on sustainable construction practices, and the imperative for resilient flood control and erosion management solutions. Industry analysts project a compound annual growth rate (CAGR) of over 5% for gabion structures through 2028, with a significant portion attributed to welded mesh variants due to their superior structural rigidity and ease of installation.

Key trends include:

- Sustainability Integration: Growing preference for materials that are recyclable and reduce the carbon footprint of projects. Gabions, filled with locally sourced stone, align perfectly with this trend.

- Advanced Coatings: Evolution of anti-corrosion coatings, including Galfan (Zn-5%Al-MM) alloy and PVC coatings, extending the service life of structures significantly, especially in aggressive environments.

- Modular and Prefabricated Solutions: Increased demand for prefabricated gabion welded wire mesh units that can be rapidly deployed, reducing on-site labor costs and construction timelines.

- Smart Gabion Systems: Emerging interest in integrating sensors within gabion structures for real-time monitoring of settlement, deformation, and water pressure, enhancing predictive maintenance capabilities.

Technical Specifications and Material Excellence

The performance of a welded mesh gabion is fundamentally dictated by its technical specifications. Our products adhere to stringent international standards, ensuring reliability and structural integrity across diverse applications. The primary material used is high-tensile steel wire, precisely manufactured to meet or exceed relevant specifications.

Wire Specifications:

- Material: Low carbon steel wire (ASTM A641, EN 10223-4 compliant).

- Wire Diameter: Typically ranges from 2.5 mm to 5.0 mm (0.098 in to 0.197 in), selected based on structural requirements and anticipated loads.

- Tensile Strength: Minimum 380 N/mm² (55,000 psi), ensuring robust performance under stress.

- Zinc Coating (Galvanization): Class A, B, or C per ASTM A90/A90M, with a minimum coating weight of 245 g/m² for enhanced corrosion resistance.

- Galfan Coating (Zn-5%Al-MM): Superior corrosion resistance, typically 2-3 times that of standard galvanization, offering extended service life in harsh environments.

- PVC Coating: An additional layer (typically 0.5 mm thick) over galvanized or Galfan wire, providing maximum corrosion protection and abrasion resistance, crucial for marine or highly acidic conditions.

Mesh Size and Configuration:

The mesh opening is a critical parameter, influencing the structural integrity and retention capabilities. Common mesh sizes for welded mesh gabion baskets include:

- 50 mm x 50 mm (2 in x 2 in)

- 75 mm x 75 mm (3 in x 3 in)

- 75 mm x 100 mm (3 in x 4 in)

- 100 mm x 100 mm (4 in x 4 in)

The selection of mesh size depends on the infill material and the hydraulic or structural forces the gabion will encounter.

Typical Product Specifications:

The Manufacturing Process of Welded Mesh Gabion

Our commitment to quality begins with a meticulously controlled manufacturing process, ensuring every gabion welded wire mesh product meets the highest industry standards. The process integrates advanced technology with rigorous quality checks.

Detailed Process Flow:

1. Material Selection & Preparation

High-grade low carbon steel rods are sourced, ensuring compliance with ASTM A641 or EN 10223-4. Rods undergo descaling and cold drawing to achieve precise wire diameters required for gabion manufacturing. This foundational step ensures the mechanical properties of the final wire.

2. Wire Galvanization/Galfan Coating

The drawn wire is passed through a hot-dip galvanizing line or a Galfan (Zn-5%Al-MM) coating process. This application of a protective metallic layer, typically 245 g/m² for galvanization or 260 g/m² for Galfan, is crucial for corrosion resistance. Adherence and uniformity of the coating are continuously monitored.

3. PVC Coating (Optional)

For applications requiring superior chemical and abrasion resistance, galvanized or Galfan wires are further coated with a durable PVC layer (typically 0.5 mm thickness). This process involves extrusion or fluidized bed coating, ensuring complete encapsulation and protection of the wire.

4. Automated Wire Welding

Using advanced CNC-controlled multi-spot welding machines, the coated wires are precision welded to form mesh panels with specified mesh openings. Each intersection is electrically welded, ensuring a strong, rigid, and uniform panel. This differs significantly from woven gabions, offering higher dimensional stability.

5. Panel Cutting & Assembly

The welded mesh panels are cut to precise dimensions for the gabion faces, sides, bases, lids, and internal diaphragms. These individual panels are then collated and typically delivered flat-packed to minimize shipping volume. For specific orders, pre-assembly into modular units can be done.

6. Quality Control & Testing

Throughout the entire process, rigorous quality control is maintained. This includes wire diameter checks, coating thickness verification (ASTM A90/A90M), tensile strength tests (ISO 6892-1), mesh opening accuracy, and weld strength tests. Final products are inspected for dimensional conformity and surface finish.

Testing Standards and Service Life:

Our welded mesh gabion products are manufactured and tested in accordance with international standards such as ISO 9001 (Quality Management Systems), ASTM A975 (Standard Specification for Double-Twisted Hexagonal Mesh Gabions and Revet Mattresses), and EN 10223-4 (Steel wire and wire products for fencing and netting – Part 4: Steel wire welded mesh fencing). Depending on the coating type and environmental conditions, the service life of our gabions can range from 25 years (heavy galvanized) to over 75 years (Galfan + PVC coated) in typical soil conditions.

Technical Advantages of Welded Mesh Gabion Baskets

The selection of welded mesh gabion baskets over other retaining wall systems is driven by a host of compelling technical advantages:

- Superior Rigidity and Dimensional Stability: The welding at each intersection creates a rigid unit, maintaining its shape during filling and settlement. This ensures a clean, uniform aesthetic, particularly vital for architectural applications.

- Enhanced Structural Integrity: The robust nature of the welded mesh panels contributes to a monolithic structure that can withstand significant earth pressures and dynamic loads, making it ideal for critical infrastructure.

- Excellent Permeability and Drainage: The open mesh structure, filled with aggregate, allows for free passage of water, effectively dissipating hydrostatic pressure behind the wall. This mitigates the risk of structural failure due to water accumulation and erosion, a key advantage in hydraulic engineering.

- Flexibility and Adaptability: While rigid, the overall gabion structure retains a degree of flexibility, allowing it to conform to ground settlement without losing structural integrity. This is particularly advantageous in areas prone to seismic activity or unstable ground conditions.

- Corrosion Resistance and Durability: With heavy galvanization, Galfan coating, or PVC coating, our gabion welded wire mesh products offer exceptional resistance to corrosion, ensuring a long service life even in harsh and aggressive environments such as coastal areas or industrial sites.

- Environmental Sustainability: Utilization of locally sourced infill materials minimizes transportation costs and carbon footprint. The permeable nature promotes vegetative growth, integrating the structure into the natural landscape and enhancing biodiversity.

- Cost-Effectiveness: Reduced construction time due to simpler assembly, lower labor requirements, and the use of readily available fill materials significantly cut down overall project costs. The long service life further enhances their economic appeal.

- Ease of Installation: Flat-packed units are easy to transport and assemble on-site with minimal specialized tools or labor, accelerating project completion.

Application Scenarios and Target Industries

The versatility of welded mesh gabion solutions makes them suitable for a wide array of applications across various industries:

- Civil Engineering & Infrastructure:

- Retaining Walls: For highway embankments, railway lines, and bridge abutments, providing stable and durable earth retention.

- Erosion Control: River training, canal lining, dam protection, and scour protection in water supply & drainage projects.

- Slope Stabilization: Preventing landslides and ensuring stability on steep slopes in mining, petrochemical, and construction sectors.

- Hydraulic Engineering:

- Weirs and Groynes: Managing water flow and sediment transport in rivers and coastal areas.

- Channel Linings: Stabilizing water channels and preventing erosion in irrigation and flood control systems.

- Landscape Architecture & Urban Planning:

- Architectural Features: Creating visually appealing facades, decorative walls, and noise barriers in urban developments.

- Garden Design: Terracing, raised garden beds, and seating areas in parks and private landscapes.

- Energy Sector:

- Pipeline Protection: Providing stable foundations and protection for gas and oil pipelines.

- Wind Farm Access Roads: Stabilizing access routes in challenging terrains.

In each scenario, the inherent advantages of corrosion resistance, structural integrity, and environmental compatibility translate into long-term savings and enhanced project resilience.

Customized Solutions for Unique Project Requirements

Understanding that every project presents its unique challenges, we specialize in providing customized welded mesh gabion solutions. Our engineering team collaborates closely with clients from conceptualization to deployment, ensuring that the gabion design precisely matches the specific demands of the site and application.

Our Customization Capabilities Include:

- Dimensions and Shapes: Manufacturing gabions in non-standard lengths, widths, and heights, including L-shaped or curved units for complex architectural or engineering designs.

- Wire Diameter and Mesh Size: Adjusting wire gauges and mesh apertures to optimize for specific fill materials, structural loads, or aesthetic preferences.

- Coating Systems: Offering tailored coating solutions (e.g., specific PVC colors, enhanced Galfan compositions) to meet extreme environmental conditions or blend with aesthetic requirements.

- Internal Diaphragms: Customizing the placement and quantity of internal diaphragms to provide additional structural stability for unusually large or complex gabion structures.

- Accessories: Supplying bespoke lacing wire, hog rings, spiral binders, and bracing wires tailored to the custom gabion designs for secure assembly.

- Pre-assembled Units: For large-scale projects or remote locations, we can provide partially pre-assembled units to further expedite on-site installation.

Our design process incorporates advanced CAD software and finite element analysis (FEA) to model performance under anticipated loads and conditions, ensuring optimal structural integrity and longevity for every custom gabion welded wire mesh solution.

Vendor Comparison: Choosing Your Welded Mesh Gabion Partner

Selecting the right supplier for welded mesh gabion baskets is crucial for project success. A comparison based on key criteria highlights our distinctive value proposition.

Our commitment to engineering excellence, comprehensive product range, and dedicated technical support positions us as the preferred partner for complex and demanding projects. We prioritize delivering not just a product, but a complete, reliable, and sustainable solution.

Application Case Studies

Our welded mesh gabion solutions have been successfully deployed in a multitude of challenging environments globally. Here are a few examples showcasing their efficacy and versatility:

Case Study 1: Highway Embankment Stabilization, Mountain Region

Client: State Department of Transportation, North America

Challenge: A critical section of a major highway in a seismically active mountain region was experiencing persistent erosion and slope instability, posing significant safety risks. The solution required high structural integrity, flexibility to accommodate minor ground movement, and environmental integration.

Solution: Over 5,000 cubic meters of heavy-galvanized welded mesh gabion baskets (3m x 1m x 1m) were installed as a tiered retaining wall system. The specific mesh size (75x75mm) and 4.0mm wire diameter were chosen for optimal stone retention and load distribution. Geotextile was utilized behind the gabion walls to prevent fine soil washout. The project was completed in 12 weeks, significantly faster than conventional concrete retaining wall options.

Outcome: The gabion system successfully stabilized the embankment, withstanding subsequent minor seismic events without damage. The permeable nature allowed native vegetation to establish, enhancing ecological integration and visual appeal. The DOT reported a 30% cost saving compared to initial estimates for a cast-in-place concrete structure, validating the economic and engineering advantages.

Case Study 2: Coastal Revetment for Industrial Facility, Southeast Asia

Client: Major Petrochemical Complex

Challenge: An industrial facility situated on a coastline required robust erosion protection against tidal action and storm surges. The highly corrosive marine environment demanded a solution with exceptional longevity and resistance to saltwater and abrasion.

Solution: A multi-layered revetment system was designed using PVC-coated gabion welded wire mesh units (2m x 1m x 0.5m). The PVC coating, applied over a Galfan base, provided maximum protection against the aggressive marine conditions. The gabions were filled with local granite aggregate, chosen for its density and abrasion resistance. Specialized geotechnical engineers oversaw the installation, ensuring proper foundation and interlocking of units.

Outcome: The revetment has successfully protected the facility for over 15 years, showing minimal signs of wear or corrosion, despite several significant storm events. The client experienced reduced maintenance costs and enhanced operational security, directly attributable to the superior protection offered by the PVC-coated gabions. Environmental impact was minimized through the use of locally sourced stone and the permeable structure.

Trustworthiness & Client Assurance

Frequently Asked Questions (FAQ)

Q1: What is the typical service life of your welded mesh gabion products?

A1: The service life varies based on the coating. Heavy galvanized gabions typically last 25-30 years. Galfan-coated units extend this to 50-75 years, while Galfan combined with PVC coating can exceed 75-100 years, even in aggressive environments.

Q2: Are your gabions suitable for marine or saltwater applications?

A2: Yes, for such applications, we highly recommend our PVC-coated gabion welded wire mesh products. The PVC provides an additional layer of protection against chloride attack and abrasion, ensuring superior longevity.

Q3: What kind of infill material can be used?

A3: Gabions can be filled with a variety of materials including natural stone, crushed concrete, river rock, or other inert, durable aggregates. The infill material should be non-biodegradable, hard, and have an appropriate size range for the mesh opening to prevent washout.

Q4: How are the gabion units assembled on-site?

A4: Our welded mesh gabion baskets are supplied flat-packed and are easily assembled by erecting the panels and securing the edges with lacing wire, spiral binders, or hog rings. Internal bracing wires are installed during filling to maintain the box shape. Detailed installation guides are provided.

Lead Time & Fulfillment

For standard welded mesh gabion orders, our typical lead time is 2-4 weeks from order confirmation to dispatch. Custom orders may require additional time, depending on complexity and material availability, which will be clearly communicated during the quotation phase. We maintain robust supply chain logistics to ensure timely and efficient delivery to project sites globally.

Warranty Commitments

We stand by the quality and durability of our products. All our welded mesh gabion solutions come with a minimum 10-year warranty against manufacturing defects and material failures under normal usage conditions. Specific coating warranties (e.g., against premature corrosion) can extend up to 25-75 years, depending on the chosen coating system and documented environmental conditions. Full warranty details are available upon request.

Customer Support & After-Sales Service

Our commitment extends beyond product delivery. We offer comprehensive pre-sales consultation, technical design assistance, and robust after-sales support. Our experienced engineering team is available to provide guidance on installation, infill selection, and maintenance. We ensure responsive communication and swift resolution of any queries or concerns, cementing long-term partnerships with our clients.

Conclusion

The welded mesh gabion represents a cornerstone of modern civil and environmental engineering. Its blend of structural integrity, environmental compatibility, and economic efficiency positions it as an unparalleled choice for a myriad of applications, from critical infrastructure protection to aesthetically driven landscape designs. By adhering to rigorous manufacturing standards, offering extensive customization, and providing comprehensive technical support, we ensure that our welded mesh gabion baskets deliver long-term value and superior performance for every project.

Embrace the proven reliability and innovative adaptability of our gabion solutions to achieve sustainable and resilient project outcomes. Our expertise and commitment to quality are your assurance of success.

References

- Gabion Construction Manual. (2018). International Gabion Manufacturers Association.

- ASTM A975/A975M-11(2017) Standard Specification for Double-Twisted Hexagonal Mesh Gabions and Revet Mattresses. ASTM International.

- EN 10223-4:2012 Steel wire and wire products for fencing and netting - Part 4: Steel wire welded mesh fencing. European Committee for Standardization.

- Jones, D. E. (2007). Geotechnical Engineering Handbook for Highway and Bridge Foundations. McGraw-Hill Professional.

- Federal Highway Administration. (2009). Hydraulic Engineering Circular No. 23: Bridge Scour and Stream Instability Countermeasures. U.S. Department of Transportation.

-

Custom Welded Wire Mesh: Durable, Versatile, and Sustainable Solutions for Global Applications

NewsNov.24,2025

-

Custom Weld Mesh – Tailored Solutions for Durable Industrial Fencing & Construction

NewsNov.24,2025

-

Comprehensive Guide to Chicken Welded Wire Mesh: Uses, Benefits & Suppliers

NewsNov.23,2025

-

BRC Weld Mesh – Durable Reinforcement Solutions for Modern Construction

NewsNov.23,2025

-

Durable BRC 3315 Mesh for Reliable Concrete Reinforcement | Hardware In Store

NewsNov.23,2025

-

Discover the Benefits of Green Weld Mesh – Durable, Sustainable Fencing Solutions

NewsNov.22,2025

Products categories