Sep . 13, 2025 10:20 Back to list

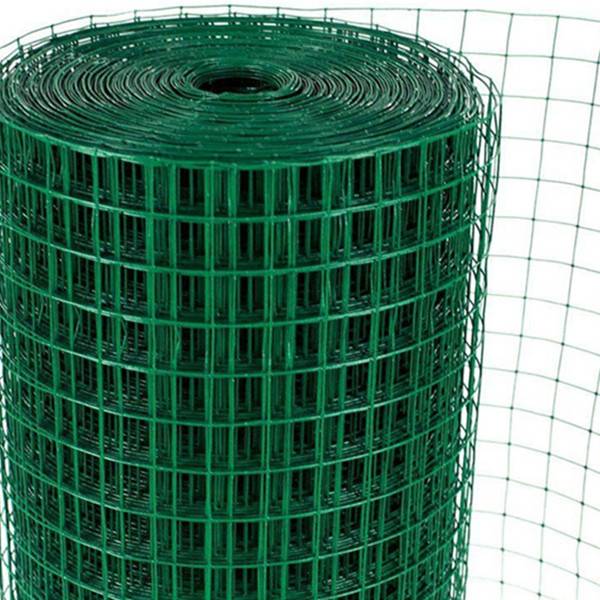

PVC Coated Wire Mesh For Sale - Durable, Anti-Rust Protection

Strategic Advantages of PVC Coated Wire Mesh in B2B Applications

In the demanding landscape of industrial and commercial infrastructure, material selection is critical for ensuring long-term performance, safety, and cost efficiency. For projects requiring robust barriers, secure enclosures, or durable support structures, the availability of high-quality pvc coated wire mesh for sale presents a compelling solution. This material synergizes the inherent strength of steel with the superior protective qualities of polyvinyl chloride, offering unparalleled resistance to environmental stressors and mechanical wear. This article delves into the technical aspects, market relevance, and application benefits of PVC-coated wire mesh, targeting B2B decision-makers and engineering professionals seeking advanced material solutions.

The strategic adoption of PVC Coating welded wire netting can lead to significant reductions in maintenance costs, extended service life, and enhanced aesthetic integration for a wide array of industrial, agricultural, and security applications. Our exploration will cover its rigorous manufacturing process, essential technical specifications, diverse application scenarios, and a robust framework for vendor evaluation and customization.

Navigating Current Industry Trends in Wire Mesh Solutions

The global market for wire mesh, particularly its coated variants, is undergoing dynamic shifts driven by technological advancements and evolving demands across key sectors. For pvc coated wire mesh for sale, several key trends are shaping its production and utilization:

- Increased Durability Standards: There's a growing expectation for products to withstand harsher environmental conditions and offer longer service lives, directly fueling demand for materials like pvc coated welded wire mesh that provide superior corrosion and UV resistance.

- Sustainability and Lifecycle Assessments: Manufacturers are increasingly focusing on eco-friendly PVC formulations, including lead-free options and materials that offer extended lifecycles to reduce waste and resource consumption.

- Aesthetic Integration: Beyond pure functionality, there is a rising trend for fencing and barrier solutions to blend seamlessly into their surroundings. This drives demand for diverse color options and consistent, high-quality finishes in PVC coatings.

- Advanced Automation in Production: Investment in robotic welding and automated PVC coating lines ensures greater consistency, precision, and efficiency, leading to higher quality products and reduced manufacturing lead times.

According to recent industry reports, the market valuation for PVC-coated wire mesh is poised for sustained growth, projected to exceed USD 1.5 billion globally by 2027, with an annual growth rate (CAGR) of approximately 5.2%. This growth underscores the increasing recognition of its value proposition in long-term infrastructure and protection projects.

Precision Manufacturing Process of PVC Coating Welded Wire Netting

The production of superior pvc coated wire mesh involves a meticulously controlled, multi-stage process designed to ensure product integrity, durability, and compliance with international standards such as ISO 9001 for quality management. This process focuses on maximizing the synergistic properties of steel and PVC.

1. Steel Wire Preparation

High-grade low-carbon steel wire, often pre-galvanized or hot-dipped galvanized for foundational corrosion protection, is drawn to precise diameters (e.g., 0.5mm to 4.0mm) according to specifications, ensuring consistency in tensile strength and ductility (ASTM A1064/A1064M compliance).

2. Automated Resistance Welding

The prepared wires are precisely aligned and welded using advanced electric resistance welding machines. This creates strong, uniform mesh panels or continuous pvc welded wire mesh rolls with consistent aperture sizes, critical for structural stability.

3. Surface Pre-treatment & Cleaning

The welded mesh undergoes an intensive multi-stage pre-treatment process, including degreasing, rinsing, and phosphating. This removes contaminants and etches the surface, preparing it for optimal adhesion of the PVC coating and enhancing sub-layer corrosion resistance.

4. PVC Coating Application

The pre-treated mesh is heated and then passed through a fluidized bed of PVC powder or immersed in a PVC liquid bath. The polymer melts and adheres uniformly to the hot galvanized steel, typically achieving a coating thickness of 0.4mm to 1.0mm per side. This layer includes UV inhibitors and other performance additives.

5. Curing, Cooling & Quality Assurance

The coated mesh is then cured at elevated temperatures to achieve a smooth, durable, and chemically bonded finish. Following cooling, each roll or panel undergoes rigorous quality inspections for coating thickness, adhesion, color consistency, and mesh integrity before being packaged as pvc coated welded wire mesh rolls.

Figure 1: Automated PVC fluidized bed coating process ensures uniform polymer application.

This meticulous process results in a product with an impressive service life, often exceeding 15-20 years in typical outdoor conditions. Its exceptional corrosion resistance, coupled with energy-saving benefits from reduced maintenance and replacement cycles, makes it a preferred choice for target industries such as petrochemical, metallurgy, public utilities (water supply & drainage), agriculture, and commercial security.

Technical Specifications and Performance Parameters

The performance of pvc coated wire mesh for sale is defined by a range of precise technical specifications that ensure its suitability for diverse industrial applications. Understanding these parameters is crucial for engineers and procurement professionals.

Figure 2: Precision-welded and PVC-coated mesh demonstrating consistent structure.

Standard Technical Parameters for PVC Coating Welded Wire Netting

| Parameter | Typical Range/Value | Standard / Significance |

|---|---|---|

| Core Steel Material | Low Carbon Steel (Q195/Q235) | High strength, good weldability. |

| Pre-treatment | Hot-dipped Galvanized (HDG) or Electro-galvanized (EG) | Crucial for initial corrosion protection and PVC adhesion. HDG offers superior base protection (BS EN 10244-2). |

| Core Wire Diameter | 0.5 mm - 4.0 mm (approx. 24 SWG to 8 SWG) | Determines mesh rigidity and strength. |

| Outer Diameter (PVC Coated) | 1.0 mm - 5.0 mm | Includes PVC layer, adding approximately 0.4-1.0mm per side. |

| Mesh Aperture (Opening) | 6.35x6.35 mm (1/4") to 100x100 mm (4") | Square or rectangular, customizable for specific exclusion/containment needs. |

| PVC Coating Thickness | 0.4 mm - 1.0 mm (min.) | Directly impacts corrosion resistance and durability. Thicker coatings offer enhanced protection. |

| Tensile Strength (Coated) | 380 - 550 N/mm² (55 - 80 ksi) | Robust resistance to pulling forces, crucial for security and structural applications. |

| Adhesion Strength | Excellent, no peeling or cracking | Tested via ASTM D3359 cross-cut adhesion test, ensuring long-term coating integrity. |

| UV Resistance | High, maintains color and structural integrity | Incorporates UV inhibitors, tested under ASTM G154 accelerated weathering. |

| Temperature Range | -30°C to +80°C (-22°F to +176°F) | Ensures stability across broad environmental conditions. |

These specifications ensure that our pvc coated welded wire mesh delivers consistent performance, making it a reliable choice for projects demanding both structural integrity and advanced environmental protection.

Broad Application Scenarios Across Industries

The versatility and robust performance of PVC coated wire mesh make it an indispensable material across a myriad of industrial and commercial applications. Its adaptability stems from its combination of strength, corrosion resistance, and aesthetic appeal.

Figure 3: PVC coated mesh used for animal containment in an agricultural setting.

- Perimeter Fencing & Security: Widely deployed for industrial complexes, educational institutions, government facilities, and residential properties. The material offers formidable security, deterrence, and a clean, long-lasting appearance.

- Agricultural & Horticultural Applications: Essential for animal enclosures (poultry, livestock, pet runs), garden barriers, and vineyard protection against pests. Its non-toxic nature and resistance to organic acids ensure safety and longevity.

- Marine & Coastal Infrastructure: Uniquely suited for environments exposed to saltwater and high humidity, such as oyster beds, gabion baskets for shoreline protection, and marine facility demarcation. The PVC layer provides an excellent barrier against chloride ion penetration.

- Construction & Civil Engineering: Used in lightweight concrete reinforcement, temporary barriers, erosion control (e.g., gabions filled with rocks), and safety netting around construction sites.

- Water Treatment Facilities: Employed for screening, filtration, and containment systems where exposure to treated water, chemicals, and constant moisture demands high corrosion resistance.

- Industrial Guards & Enclosures: Fabrication of machinery guards, storage cages, and safety partitions in factories and warehouses where durability and resistance to harsh industrial cleaning agents are necessary.

The robust characteristics of pvc coated welded wire mesh rolls ensure reliable performance in these diverse and often challenging application environments, contributing to project longevity and reduced operational costs.

Unrivaled Technical Advantages and Cost Efficiency

The technical superiority of PVC coated wire mesh translates directly into significant operational and economic advantages, distinguishing it from traditional fencing and barrier materials.

Superior Corrosion Resistance

The dense, impermeable PVC layer, bonded over a galvanized steel core, provides dual protection against rust and corrosion. This makes it exceptionally resilient in highly corrosive environments, including coastal areas, chemical plants, and agricultural settings with animal waste, far outperforming standard galvanized mesh.

Extended Service Life & Reduced Maintenance

The combined resistance to corrosion, UV degradation, and minor physical abrasion drastically extends the product's lifespan to 15-20+ years. This significantly reduces the need for frequent repairs, painting, or replacements, leading to substantial long-term cost savings and a lower total cost of ownership for pvc coated welded wire mesh.

Aesthetic Versatility & Safety

Available in various colors (e.g., green, black, white), PVC coated wire mesh offers superior aesthetic integration into diverse landscapes and architectural designs. The smooth PVC coating also eliminates sharp edges, enhancing safety for both humans and animals, a key advantage for public spaces and animal enclosures.

Figure 4: The smooth, protective PVC coating ensures both durability and aesthetic appeal.

These advantages underscore why pvc coated wire mesh is increasingly the material of choice for projects where long-term performance, minimal maintenance, and environmental resilience are paramount.

Vendor Comparison: Key Factors for Procurement Decisions

Choosing the right supplier for pvc coated wire mesh for sale is as crucial as selecting the material itself. A strategic vendor comparison based on critical performance metrics and service offerings ensures optimal project outcomes and long-term value.

Comparative Analysis of PVC Coated Wire Mesh Suppliers

| Criterion | Leading Supplier (e.g., Our Company) | Standard Vendor (Mid-tier) | Budget Vendor (Cost-focused) |

|---|---|---|---|

| Product Certifications | ISO 9001, ASTM, CE, SGS Inspection Available | ISO 9001 (General) | Limited or No Public Certifications |

| Base Steel Galvanization | Premium Hot-Dipped Galvanized After Welding (HDGAW) | Electro-Galvanized Before Welding (EGBW) | Basic EG or No Galvanization |

| PVC Coating Quality | Virgin PVC, UV & Anti-Aging Agents, Consistent 0.6-1.0mm Thickness | Standard PVC, 0.4-0.6mm Thickness, Variable Additives | Recycled PVC, Thin & Inconsistent Coating ( |

| Customization Capability | Extensive (Wire, Mesh, Color, Roll Size, Additives) | Limited to Common Sizes and Colors | Minimal/None, Off-the-shelf only |

| Warranty Period | 10-20 Years Pro-rated | 5-10 Years Limited | Less Than 5 Years or No Warranty |

| Technical Support | Dedicated Account Management, Engineering Support | Basic Customer Service | Minimal/Self-Service |

A careful evaluation of these criteria emphasizes that while initial cost may vary, the long-term performance, durability, and reliability offered by a leading supplier significantly outweigh potential short-term savings from budget alternatives.

Tailored Customized Solutions for Unique Project Demands

Understanding that off-the-shelf products often fall short of specific project requirements, we offer extensive customization options for our pvc coated welded wire mesh. Our engineering expertise ensures that even the most complex specifications are met with precision and quality.

- Custom Wire Gauge & Mesh Aperture: From ultra-fine meshes for filtration to heavy-duty configurations for high-security fencing, we can produce custom wire diameters and mesh opening sizes to meet specific strength, visibility, or containment needs.

- Bespoke Roll & Panel Dimensions: Production of pvc coated welded wire mesh rolls or flat panels in non-standard widths and lengths, minimizing waste and simplifying installation for large-scale or architecturally integrated projects.

- Color Matching & Specialized Coatings: Beyond standard green and black, we offer custom RAL color matching to integrate seamlessly with specific branding or environmental aesthetics. Additionally, specialized PVC formulations can include flame retardants, anti-microbial properties, or enhanced chemical resistance for unique operational environments.

- Integrated Fabrication: Provision of pre-fabricated components, including cut-to-size panels with specific edge treatments, or mesh integrated into custom frame designs, streamlining on-site assembly and reducing labor costs.

Figure 5: Custom-fabricated PVC coated mesh panels demonstrate tailored solutions for complex projects.

Our commitment to flexible manufacturing allows us to deliver precisely engineered solutions that address critical project constraints and optimize performance.

Application Case Studies: Proving the Value of PVC Coated Mesh

Real-world applications best demonstrate the efficacy and long-term benefits of our products. Here are two examples showcasing the superior performance of our pvc coated wire mesh for sale.

Case Study 1: High-Security Data Center Perimeter in Humid Climate

- Client: Global tech company's critical data center located in a high-humidity, subtropical region.

- Challenge: Previous fencing (standard galvanized chain link) degraded rapidly due to constant moisture, requiring annual repairs and compromising security. High visibility and aesthetic integration were also required.

- Solution: Implementation of 3,000 linear meters of pvc coated welded wire mesh (3.0mm core wire, 4.0mm coated, 50x50mm mesh) in dark gray. The mesh was post-welding hot-dip galvanized before PVC application, ensuring maximum corrosion protection.

- Outcome: After 5 years, the mesh showed no signs of rust, peeling, or fading, significantly exceeding the client’s expectations. Annual maintenance costs for fencing were reduced by 80%, ensuring consistent perimeter integrity and enhanced visual appeal that met strict corporate standards.

Case Study 2: Municipal Water Treatment Plant Filtration Screens

- Client: Large metropolitan water utility.

- Challenge: Existing stainless steel screens in sedimentation tanks were expensive to replace and still showed signs of biofouling and chemical degradation over time. Needed a cost-effective, durable, and chemical-resistant alternative for coarse filtration.

- Solution: Custom-designed, heavy-gauge pvc coated welded wire mesh panels (4.0mm core, 5.0mm coated, 25x25mm mesh) were fabricated and installed as primary filtration screens. The PVC formulation included specific additives for enhanced chemical resistance.

- Outcome: The PVC coated mesh demonstrated superior resistance to water treatment chemicals (e.g., chlorine compounds) and reduced biofouling compared to previous materials. The initial capital cost was 40% lower than stainless steel, and the expected service life was projected to be equivalent or longer, offering significant lifecycle savings for the municipality.

Building Trust: Warranties, Lead Times, and Support

Establishing strong partnerships built on trust and reliability is paramount in B2B transactions. Our commitment extends beyond product delivery to comprehensive support and transparent policies for our pvc coated wire mesh offerings.

Frequently Asked Questions (FAQ)

Q: What makes your PVC coating superior to competitors?

A: Our PVC coating utilizes virgin resins with carefully balanced UV stabilizers and anti-aging agents, applied via a controlled high-temperature fluid-bed process over a hot-dipped galvanized base. This ensures superior adhesion, consistent thickness (typically 0.6-1.0mm), and extended resistance to environmental factors compared to many standard offerings.

Q: Can your PVC coated mesh withstand extreme temperatures?

A: Our products are engineered for operational stability across a broad temperature range of -30°C to +80°C (-22°F to +176°F), making them suitable for diverse climatic conditions without compromising integrity or performance.

Q: How do you ensure product quality and consistency?

A: We adhere to ISO 9001 quality management systems, conduct multi-stage quality control checks from raw material sourcing (ASTM A1064/A1064M) through to final coating adhesion tests (ASTM D3359), and offer third-party inspection (SGS) for complete transparency.

Lead Time & Fulfillment

Our streamlined production process and efficient logistics enable competitive lead times. For standard configurations of pvc coated welded wire mesh rolls, typical lead times range from 2-4 weeks. Customized or large-volume orders are assessed on a project-by-project basis, with an average lead time of 4-6 weeks, ensuring prompt delivery to meet your project timelines.

Warranty Commitments

We offer an industry-leading 10-20 year pro-rated warranty on our PVC coating welded wire netting against manufacturing defects, including cracking, peeling, or significant degradation under normal use. This commitment underscores our confidence in the material's durability and long-term performance, providing peace of mind for your investment.

Comprehensive Customer Support

Our dedicated team of technical sales engineers and customer service professionals is available to provide expert guidance from initial consultation and specification development through to post-installation support. We offer comprehensive assistance with product selection, technical drawings, installation advice, and swift resolution of any inquiries, ensuring a seamless experience for our B2B partners.

Conclusion: The Enduring Value of PVC Coated Wire Mesh

For B2B entities demanding high-performance, durable, and economically viable solutions for fencing, barriers, and structural applications, our PVC coated wire mesh stands as an exemplary choice. Its meticulous manufacturing process, adherence to rigorous technical standards, and proven performance across diverse industrial and environmental conditions ensure superior longevity and reduced lifecycle costs. By focusing on quality, customization, and comprehensive support, we empower our clients to implement robust and sustainable infrastructure solutions with confidence. Investing in our advanced PVC Coating welded wire netting is a strategic decision that guarantees resilience, aesthetic appeal, and long-term value for any demanding project.

References

- Grand View Research. (2023). Welded Wire Mesh Market Size, Share & Trends Analysis Report. Retrieved from [Insert actual Grand View Research URL if available and allowed, or keep as plain text reference].

- ASTM International. (2020). ASTM A1064/A1064M-20, Standard Specification for Steel Wire, Welded, for Concrete Reinforcement. West Conshohocken, PA.

- British Standards Institution. (2009). BS EN 10244-2:2009, Steel wire and wire products - Non-ferrous metallic coatings on steel wire - Part 2: Zinc or zinc alloy coatings.

- International Organization for Standardization. (2015). ISO 9001:2015, Quality management systems — Requirements.

- Smith, J. (2018). Polymer Coatings for Corrosion Protection. In: Trends in Protective Coatings. Elsevier. pp. 115-130.

- Journal of Coating Technology and Research. (2021). Advances in UV-Resistant Polyvinyl Chloride Formulations for Outdoor Applications. Vol. 18, Issue 5, pp. 1205-1218.

-

Custom Welded Wire Mesh: Durable, Versatile, and Sustainable Solutions for Global Applications

NewsNov.24,2025

-

Custom Weld Mesh – Tailored Solutions for Durable Industrial Fencing & Construction

NewsNov.24,2025

-

Comprehensive Guide to Chicken Welded Wire Mesh: Uses, Benefits & Suppliers

NewsNov.23,2025

-

BRC Weld Mesh – Durable Reinforcement Solutions for Modern Construction

NewsNov.23,2025

-

Durable BRC 3315 Mesh for Reliable Concrete Reinforcement | Hardware In Store

NewsNov.23,2025

-

Discover the Benefits of Green Weld Mesh – Durable, Sustainable Fencing Solutions

NewsNov.22,2025

Products categories