Nov . 19, 2024 02:56 Back to list

Durable Stainless Steel Wire Mesh Solutions for Various Applications and Industries

The Versatility of Stainless Steel Wire Screens

Stainless steel wire screens are an essential component in a wide variety of industries, thanks to their durability, corrosion resistance, and excellent filtration capabilities. These screens have become a staple in applications ranging from industrial filtration to architectural design, showcasing their versatility and efficiency.

Composition and Properties

Stainless steel is an alloy of iron, chromium, and nickel, which gives it unique properties that make it particularly well-suited for wire screens. The presence of chromium creates a protective layer known as the passive film, which prevents rust and oxidation, even in harsh environments. This corrosion resistance is crucial for applications where exposure to moisture, chemicals, or high temperatures is a factor.

In addition to being resistant to rust, stainless steel wire is known for its strength and resilience. This means that stainless steel wire screens can be manufactured in various gauges and mesh sizes, making them adaptable to different purposes. Whether used for filtration, sieving, or even as protective barriers, the strength of stainless steel ensures that the screens maintain their integrity over time.

Applications in Filtration

One of the primary uses of stainless steel wire screens is in filtration systems. Industries such as food and beverage, pharmaceuticals, chemicals, and wastewater treatment depend on high-quality filtration to ensure product purity and compliance with safety standards. Stainless steel wire screens can effectively filter out particles, sediments, and contaminants, ensuring that only the desired materials pass through.

In the food and beverage industry, for example, stainless steel screens are crucial for liquid filtration applications, such as juice, beer, and oil production. They help remove pulp, hops, or other solids, preserving the clarity and quality of the final product. In pharmaceutical manufacturing, these screens ensure that the liquids used in developing medicines are free from contaminants that could affect efficacy and safety.

stainless steel wire screen

Architectural and Decorative Uses

Beyond industrial applications, stainless steel wire screens have also found a place in architecture and interior design

. Their aesthetic appeal, combined with their strength, makes them an attractive choice for creating decorative screens, railings, and facades. Designers appreciate the ability to allow light and air to pass through while maintaining privacy and aesthetic appeal.For instance, in modern architecture, stainless steel wire screens can be used as facades or shading devices, creating visual interest while offering functional benefits such as reducing heat gain in buildings. They can be customized to various patterns and finishes, making them suitable for diverse design styles, from minimalist to industrial chic.

Advantages Over Other Materials

When compared to other materials commonly used for screens, such as plastic or nylon, stainless steel offers significant advantages. While plastic screens may degrade over time due to UV exposure or harsh chemicals, stainless steel maintains its properties even in extreme conditions. This longevity leads to lower replacement costs and reduced environmental impact since less waste is generated over time.

Moreover, stainless steel wire screens are easy to clean and disinfect, making them ideal for industries where hygiene is paramount. Their resistance to staining and corrosion ensures that they retain their appearance and function, even after extensive use.

Conclusion

In summary, stainless steel wire screens are an indispensable element across various sectors, providing unmatched strength, durability, and versatility. From industrial filtration applications to architectural innovations, the advantages of using stainless steel as a material are clear. As industries continue to evolve and seek more sustainable and efficient solutions, the demand for stainless steel wire screens is expected to grow, solidifying their role in modern manufacturing and design. Whether for practical or aesthetic purposes, stainless steel wire screens are poised to remain at the forefront of innovation and excellence.

-

Why a Chain Link Fence is the Right Choice

NewsJul.09,2025

-

Upgrade Your Fencing with High-Quality Coated Chicken Wire

NewsJul.09,2025

-

The Power of Fence Post Spikes

NewsJul.09,2025

-

The Best Pet Enclosures for Every Need

NewsJul.09,2025

-

Secure Your Property with Premium Barbed Wire Solutions

NewsJul.09,2025

-

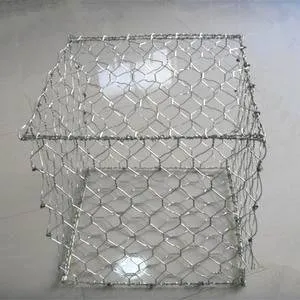

Enhance Your Construction Projects with Quality Gabion Boxes

NewsJul.09,2025

Products categories