Sep . 30, 2024 18:43 Back to list

PVC Coated Wire Versatility and Applications in Various Industries

Exploring the Versatility of PVC Coated Wire

In the ever-evolving landscape of materials used in construction, agriculture, and various industrial applications, PVC coated wire stands out due to its remarkable properties and versatility. This specialized type of wire, which is coated in a layer of polyvinyl chloride (PVC), offers a myriad of benefits that make it an ideal choice for a wide array of uses.

What is PVC Coated Wire?

PVC coated wire is essentially made from a metal core—typically steel or iron—encased in a layer of PVC. This coating enhances the wire's properties, including durability, resistance to corrosion, and aesthetic appeal. The PVC layer varies in thickness and color, allowing for customization based on specific project requirements or aesthetic preferences.

Key Benefits of PVC Coated Wire

1. Corrosion Resistance One of the standout features of PVC coated wire is its exceptional resistance to corrosion. Unlike untreated metal, which can deteriorate when exposed to moisture and environmental conditions, PVC coated wire maintains its integrity over time. This makes it ideal for outdoor applications where exposure to weather elements is a concern.

2. Increased Longevity The protective coating significantly extends the lifespan of the wire. Industries that utilize this wire can expect reduced maintenance costs and fewer replacements, yielding better long-term investment outcomes.

3. Safety Features The PVC coating serves as an insulating layer, reducing the risk of electrical conduction. This features makes PVC coated wire suitable for applications that require electrical insulation, providing a safer environment for both workers and equipment.

4. Aesthetic Appeal Available in various colors, PVC coated wire can be chosen to complement the design of a project. Whether used for fencing, decorative purposes, or construction, the visual aspect is often just as important as functionality.

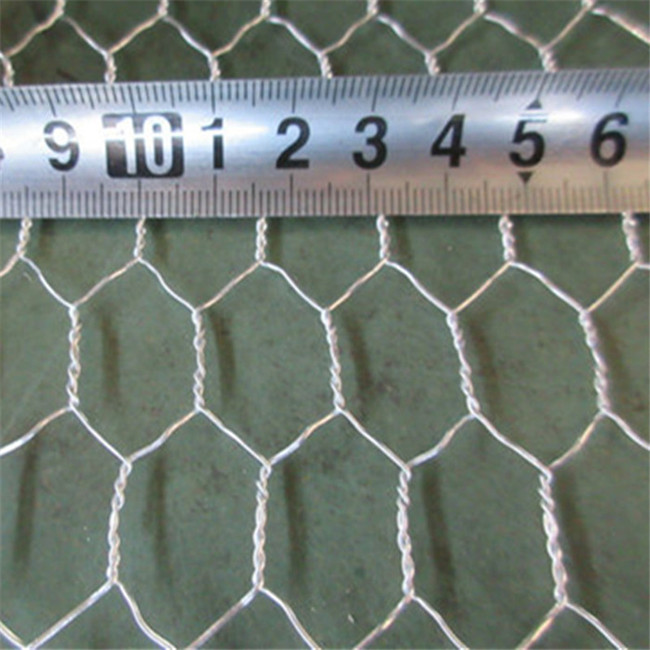

pvc coated wire

5. Flexibility and Ease of Use PVC coated wire is relatively lightweight and easy to handle. This flexibility simplifies installation processes, whether the wire is used for fencing, wiring in agriculture, or reinforcement in construction.

Applications of PVC Coated Wire

The applications of PVC coated wire are extensive and diverse

- Fencing It is widely used in the construction of fences, especially for agricultural purposes. The corrosion resistance and aesthetic options make it a popular choice for perimeter fencing, garden decorations, and animal enclosures.

- Electronics and Electrical Work In environments where insulation is necessary, PVC coated wire is a go-to option. Its ability to prevent electrical conduction enhances safety in electronic devices and installations.

- Construction The wire is often used in various construction applications for reinforcing concrete structures, offering both strength and durability due to its corrosion-resistant properties.

- Sports and Leisure PVC coated wire can also be found in sports facilities. For instance, it is used in the construction of soccer goals, tennis courts, and other recreational areas where netting might be required.

Conclusion

In summary, PVC coated wire is a versatile material that stands out in many applications due to its numerous benefits, including corrosion resistance, increased longevity, safety features, aesthetic variety, and ease of use. Whether you are involved in construction, agriculture, or recreational applications, this type of wire presents an efficient solution tailored to diverse needs. As technology and industries continue to progress, PVC coated wire remains a reliable choice that combines affordability with high performance. Investing in PVC coated wire is not just a practical decision but also a forward-thinking one, ensuring that projects are built on a foundation of durability and reliability.

-

Why a Chain Link Fence is the Right Choice

NewsJul.09,2025

-

Upgrade Your Fencing with High-Quality Coated Chicken Wire

NewsJul.09,2025

-

The Power of Fence Post Spikes

NewsJul.09,2025

-

The Best Pet Enclosures for Every Need

NewsJul.09,2025

-

Secure Your Property with Premium Barbed Wire Solutions

NewsJul.09,2025

-

Enhance Your Construction Projects with Quality Gabion Boxes

NewsJul.09,2025

Products categories