Sep . 15, 2024 11:32 Back to list

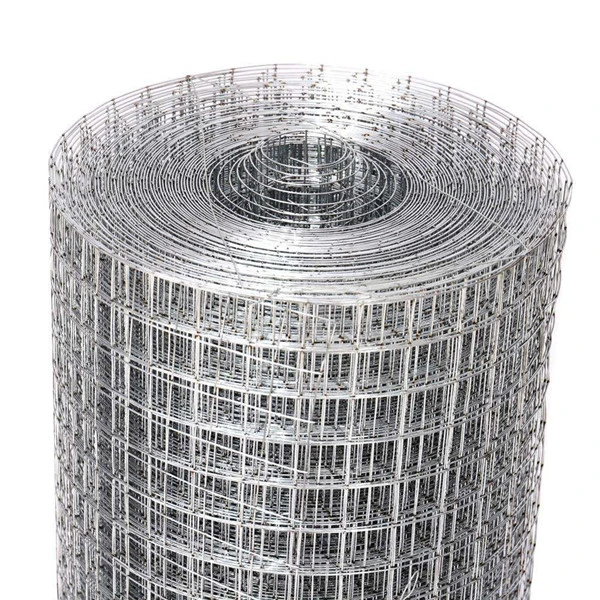

Affordable PVC Coated Wire Prices | Quality and Durability

Understanding the Price Dynamics of PVC Coated Wire

PVC coated wire is a versatile material used across various industries, from construction and agriculture to manufacturing and home improvement. This wire combines the strength and durability of metal with the added benefits of a PVC (Polyvinyl Chloride) coating, which provides resistance to corrosion, chemicals, and UV rays. As a result, PVC coated wire has become a popular choice for fencing, crafting, electrical applications, and more. However, understanding the price dynamics of PVC coated wire is crucial for consumers and businesses alike.

Factors Influencing PVC Coated Wire Prices

Several key factors influence the pricing of PVC coated wire

1. Raw Material Costs The price of the base material, usually steel or iron, plays a significant role in determining the final cost of PVC coated wire. When global markets experience fluctuations in the prices of these metals due to supply chain disruptions or increased demand, the cost of PVC coated wire inevitably rises or falls accordingly.

2. PVC Resin Prices The cost of PVC, a primary component of the coating, also impacts pricing. PVC resin prices can fluctuate based on crude oil prices, as it is derived from petroleum. An increase in oil prices often leads to higher PVC costs, thereby affecting the overall price of PVC coated wire.

3. Manufacturing Costs The expenses associated with the production process, such as labor, energy, and overhead costs, can affect the final price of the wire. If manufacturing becomes more expensive due to rising energy costs or labor shortages, these costs may be passed on to consumers.

4. Market Demand Supply and demand dynamics play a crucial role in pricing. During peak construction seasons or when agricultural activities increase, demand for PVC coated wire can surge, leading to higher prices. Conversely, in off-peak seasons, prices may stabilize or decrease.

pvc coated wire price

5. Thickness and Coating The specifications of the wire, such as its thickness, gauge, and the number of coatings applied, can also influence the price. Thicker wires or those with multiple coats of PVC will generally cost more due to the increased material and production efforts required.

6. Geographic Variation Prices may vary based on geographic location. Local market conditions, shipping costs, and tariffs can lead to different pricing structures in different regions. For instance, areas closer to manufacturing plants may enjoy lower prices compared to those further away.

Current Market Trends

As of late 2023, the PVC coated wire market has experienced various trends. In response to rising construction activity post-pandemic, demand for PVC coated wire has increased significantly. This uptick in demand is correlated with ongoing infrastructure projects and a renewed focus on housing development, thus putting upward pressure on prices.

Additionally, environmental regulations surrounding the production of metals and plastics are prompting manufacturers to invest in cleaner technologies, which can also affect production costs and, by extension, pricing.

Conclusion

For consumers and businesses considering purchasing PVC coated wire, it is essential to stay informed about the various factors that influence pricing. Understanding the interplay between raw material costs, market demand, and manufacturing expenses can help buyers navigate this essential market. By keeping abreast of market trends and fluctuations, buyers can make more informed purchasing decisions that align with their budgetary needs and project requirements. Whether for fencing, agriculture, or crafting, PVC coated wire remains a crucial and adaptable product in an ever-evolving marketplace.

-

build-a-discreet-chicken-run-with-sturdy-green-coated-chicken-wire

NewsAug.23,2025

-

a-guide-to-selecting-the-most-durable-field-gates-for-your-property

NewsAug.23,2025

-

green-mesh-fencing-rolls-offer-versatile-solutions-for-diverse-needs

NewsAug.23,2025

-

chain-fence-for-durable-and-versatile-enclosure-solutions

NewsAug.23,2025

-

garden-edging-fence-for-functional-and-decorative-landscaping

NewsAug.23,2025

-

3d-wire-mesh-fence-for-versatile-security-and-decoration

NewsAug.23,2025

Products categories