Nov . 11, 2024 03:46 Back to list

Durable Plastic-Coated Wire Mesh Sheets for Versatile Applications

Understanding Plastic Coated Wire Mesh Sheets Applications and Benefits

Wire mesh sheets are a crucial component in various industrial, commercial, and residential applications. Among the numerous types of wire mesh available, plastic coated wire mesh sheets stand out for their unique properties and benefits. This article delves into what plastic coated wire mesh sheets are, their advantages, uses, and maintenance.

What are Plastic Coated Wire Mesh Sheets?

Plastic coated wire mesh sheets are made by taking a wire mesh, typically constructed from steel or other metals, and enveloping it in a layer of plastic. The coating material can vary and often includes materials such as PVC (polyvinyl chloride) or polyethylene, providing the wire mesh with a protective barrier against environmental factors such as humidity, corrosion, and abrasion. The result is a wire mesh that combines the strength and durability of metal with the added benefits of plastic.

Advantages of Plastic Coated Wire Mesh

1. Corrosion Resistance One of the primary benefits of plastic coated wire mesh sheets is their resistance to rust and corrosion. This is particularly important in outdoor settings or environments where the mesh is exposed to moisture. The plastic coating seals the metal and prevents the infiltration of water and oxygen, both of which contribute to rust formation.

2. Enhanced Durability The added layer of plastic not only protects the wire mesh from corrosion but also increases its overall durability. This makes it an excellent choice for applications that require long-lasting materials that can withstand harsh conditions.

3. Variety of Colors Plastic coated wire mesh sheets can be produced in various colors, providing aesthetic options that can complement architectural designs or specific project requirements. This feature makes them particularly popular in landscaping and garden applications.

4. Safety and Comfort The plastic coating provides a smoother surface, minimizing sharp edges that could cause injuries. This characteristic is invaluable in applications involving animals, children, or public spaces, where safety is paramount.

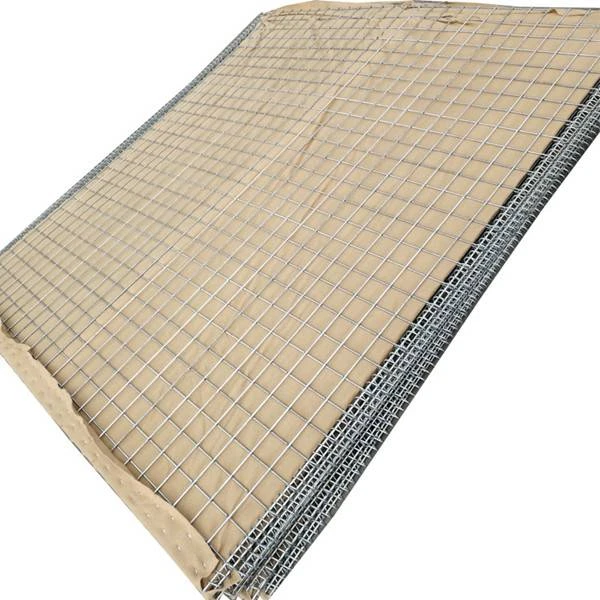

plastic coated wire mesh sheets

5. UV Resistance The plastic coating is often resistant to UV rays, preventing degradation and fading over time. This extends the lifespan of the wire mesh, making it ideal for outdoor use.

Applications of Plastic Coated Wire Mesh Sheets

Plastic coated wire mesh sheets are used across a wide range of industries and applications. Some notable uses include

- Fencing Commonly used in residential and commercial fencing solutions, plastic coated wire mesh provides security while maintaining an aesthetically pleasing appearance. - Agriculture Farmers commonly use this type of mesh for animal enclosures, garden fencing, and crop protection, taking advantage of its durability and corrosion resistance. - Construction In the construction industry, these wire mesh sheets are utilized as reinforcement in concrete structures and as a barrier for safety during building projects. - Industrial Applications Factories and warehouses utilize plastic coated wire mesh for storage racks, safety barriers, and as protective screens around machinery or hazardous materials. - Home Improvement DIY enthusiasts use plastic coated wire mesh sheets in various home improvement projects, including custom shelving, privacy screens, and decorative garden elements.

Maintenance of Plastic Coated Wire Mesh Sheets

Maintaining plastic coated wire mesh sheets is relatively easy. Regular cleaning with mild soap and water can help remove dirt and debris, preventing any buildup that could potentially degrade the plastic coating. Checking for any signs of damage or wear is also advisable, especially in high-traffic or exposed areas. Minor scratches can usually be touched up with appropriate paint or sealant to maintain the protective barrier.

Conclusion

Plastic coated wire mesh sheets offer an unparalleled combination of strength, durability, and visual appeal, making them a preferred choice across multiple sectors. Their resistance to rust, UV rays, and abrasion, alongside their versatility in application, highlight their significant role in modern construction, agriculture, and various other fields. By understanding the advantages and uses of plastic coated wire mesh sheets, businesses and individuals can make informed decisions that enhance safety, efficiency, and aesthetic appeal in their projects.

-

Why a Chain Link Fence is the Right Choice

NewsJul.09,2025

-

Upgrade Your Fencing with High-Quality Coated Chicken Wire

NewsJul.09,2025

-

The Power of Fence Post Spikes

NewsJul.09,2025

-

The Best Pet Enclosures for Every Need

NewsJul.09,2025

-

Secure Your Property with Premium Barbed Wire Solutions

NewsJul.09,2025

-

Enhance Your Construction Projects with Quality Gabion Boxes

NewsJul.09,2025

Products categories