Jan . 22, 2025 05:21 Back to list

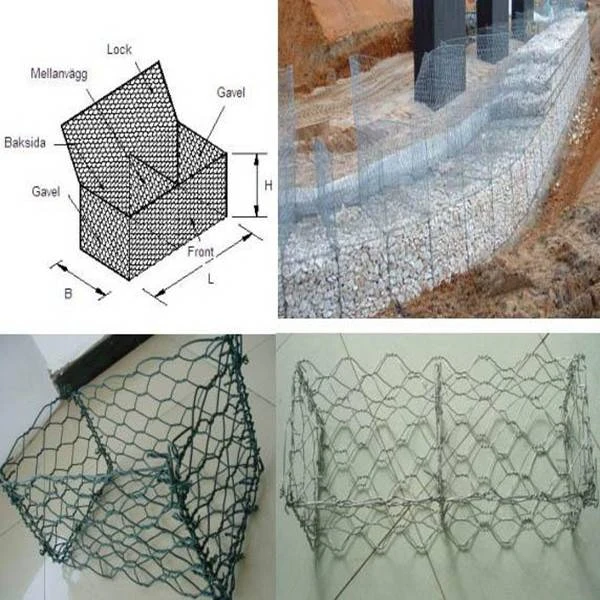

Welded Mesh Gabion

Mesh welding has revolutionized the construction industry by significantly enhancing efficiency, safety, and productivity. This advanced technology seamlessly welds intersecting wire mesh to form solid and reliable structures used in a variety of applications including building construction, road reinforcement, and industrial projects. In this article, we delve into the intricate aspects of mesh welding, drawing upon genuine experiences and professional expertise that affirm its authority and reliability in the market.

Trust in mesh welding as a reliable technology is bolstered by rigorous testing and compliance with industry standards. Manufacturers of mesh welding machines adhere to stringent quality protocols, ensuring each machine is tested against recognized standards such as ISO 9001 and ASTM specifications. These certifications provide customers with assurance that their infrastructure meets global benchmarks for safety and performance. A senior quality control inspector who works with mesh welding equipment emphasized, Our commitment to quality is non-negotiable. By following strict compliance checks, we guarantee that our clients receive machines that perform exceptionally under varied conditions. Moreover, mesh welding technology adapts to specific needs across different projects, adding an element of customization that is crucial for modern construction challenges. Whether designing mesh for security grills or road reinforcements, the adaptability of mesh welding machines ensures that unique specifications are met with high precision. A civil engineer noted the versatility of mesh welding in his recent project entailing complex architectural designs. The ability to customize mesh dimensions and strengths allows for creative freedom that wasn't possible before, he explained, pointing to how this adaptability opens doors to innovative architectural solutions. In the environmental domain, mesh welding technology contributes to sustainability efforts by reducing waste. Automated welding precisely measures and welds materials, minimizing excess and promoting efficient use of resources. Environmental consultants appreciate this eco-friendly aspect as it aligns with broader sustainability goals in construction. Speaking on the environmental impact, a consultant highlighted, Using mesh welding reduces material wastage significantly. It's a forward-thinking approach that aligns with our sustainable construction practices. In essence, mesh welding stands out as a pivotal advancement in construction technology. By increasing efficiency, ensuring precision, enhancing safety, adhering to strict quality standards, and promoting environmental sustainability, it proves itself indispensable. The insights drawn from real-world applications authenticate its value, reinforcing trust in its capabilities. As the demand for robust and sustainable construction continues to rise, mesh welding offers an authoritative and trustworthy solution for future infrastructure projects.

Trust in mesh welding as a reliable technology is bolstered by rigorous testing and compliance with industry standards. Manufacturers of mesh welding machines adhere to stringent quality protocols, ensuring each machine is tested against recognized standards such as ISO 9001 and ASTM specifications. These certifications provide customers with assurance that their infrastructure meets global benchmarks for safety and performance. A senior quality control inspector who works with mesh welding equipment emphasized, Our commitment to quality is non-negotiable. By following strict compliance checks, we guarantee that our clients receive machines that perform exceptionally under varied conditions. Moreover, mesh welding technology adapts to specific needs across different projects, adding an element of customization that is crucial for modern construction challenges. Whether designing mesh for security grills or road reinforcements, the adaptability of mesh welding machines ensures that unique specifications are met with high precision. A civil engineer noted the versatility of mesh welding in his recent project entailing complex architectural designs. The ability to customize mesh dimensions and strengths allows for creative freedom that wasn't possible before, he explained, pointing to how this adaptability opens doors to innovative architectural solutions. In the environmental domain, mesh welding technology contributes to sustainability efforts by reducing waste. Automated welding precisely measures and welds materials, minimizing excess and promoting efficient use of resources. Environmental consultants appreciate this eco-friendly aspect as it aligns with broader sustainability goals in construction. Speaking on the environmental impact, a consultant highlighted, Using mesh welding reduces material wastage significantly. It's a forward-thinking approach that aligns with our sustainable construction practices. In essence, mesh welding stands out as a pivotal advancement in construction technology. By increasing efficiency, ensuring precision, enhancing safety, adhering to strict quality standards, and promoting environmental sustainability, it proves itself indispensable. The insights drawn from real-world applications authenticate its value, reinforcing trust in its capabilities. As the demand for robust and sustainable construction continues to rise, mesh welding offers an authoritative and trustworthy solution for future infrastructure projects.

Pervious:

Next:

Latest news

-

Why a Chain Link Fence is the Right Choice

NewsJul.09,2025

-

Upgrade Your Fencing with High-Quality Coated Chicken Wire

NewsJul.09,2025

-

The Power of Fence Post Spikes

NewsJul.09,2025

-

The Best Pet Enclosures for Every Need

NewsJul.09,2025

-

Secure Your Property with Premium Barbed Wire Solutions

NewsJul.09,2025

-

Enhance Your Construction Projects with Quality Gabion Boxes

NewsJul.09,2025

Products categories

NEED HELP?

Don' t Hesitate To Contact Us For More Information About Company Or Service

CONTACT US