Aug . 28, 2024 08:35 Back to list

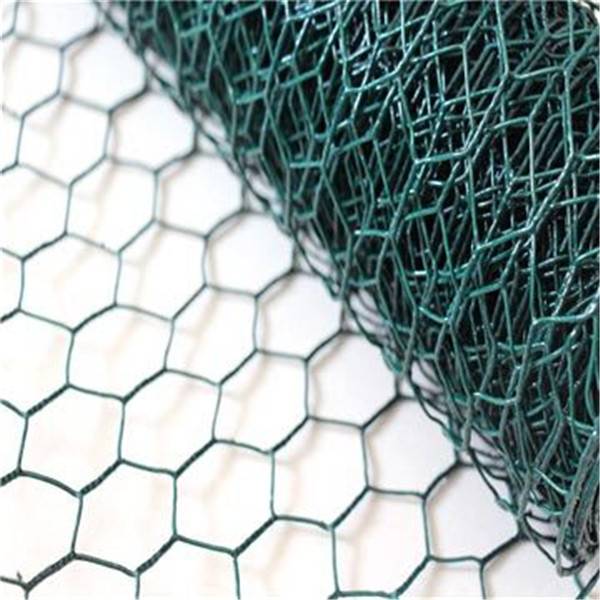

Galvanized Mesh Wire - Durable and Versatile Fencing Solutions

The Versatility of Galvanized Mesh Wire A Comprehensive Overview

Galvanized mesh wire has become an indispensable material in a variety of industries, known for its durability, strength, and resistance to corrosion. This article delves into its features, applications, and maintenance practices, presenting a well-rounded view of why galvanized mesh wire is a preferred choice for many.

Understanding Galvanized Mesh Wire

Galvanized mesh wire is made from steel wire that has undergone a galvanization process, where a protective zinc coating is applied to prevent rusting and corrosion. This technique not only enhances the wire’s longevity but also maintains its aesthetic appeal, making it suitable for both indoor and outdoor uses. The mesh can be manufactured in different sizes and thicknesses, making it adaptable for various applications.

Key Features

One of the primary advantages of galvanized mesh wire is its exceptional resistance to environmental elements. The zinc coating forms a barrier that protects the underlying steel from moisture, chemicals, and various weather conditions. Additionally, galvanized mesh wire exhibits excellent tensile strength, ensuring its capability to withstand substantial mechanical loads and pressures. Given these properties, it is often a go-to solution for fencing, reinforcement, and as a structural component in various construction projects.

Applications

Galvanized mesh wire is utilized across several fields

. Some of the most common applications include1. Fencing Its robust nature makes galvanized mesh wire an ideal choice for fencing livestock, gardens, and commercial properties. It offers security while allowing visibility and airflow.

2. Construction In construction, it is frequently used for reinforcing concrete, providing added strength and stability to structures. It's also employed in creating formwork for poured concrete.

mesh wire galvanized

3. Agriculture Farmers use galvanized mesh wire for building animal enclosures, trellises for climbing plants, and garden protection against wildlife. Its ability to resist rust makes it suitable for outdoor environments.

4. Industrial Uses In industrial settings, it functions as safety barriers, storage containers, and even in machine parts due to its structural integrity.

5. Architectural Designs In modern design, galvanized mesh wire is also used for decorative purposes, such as in facades, railings, and art installations, merging functionality with aesthetic innovation.

Maintenance

While galvanized mesh wire is designed to resist corrosion, regular maintenance can significantly extend its lifespan. Here are a few essential maintenance tips

- Inspection Periodically inspect the mesh for signs of rust or damage, particularly in areas exposed to harsh conditions.

- Cleaning Keep the mesh clean from dirt and debris, as build-up can lead to moisture retention and eventual corrosion.

- Touch-Up If any spots on the mesh are showing signs of wear through the zinc coating, applying a zinc-rich paint can help to protect those areas.

Conclusion

In conclusion, galvanized mesh wire is a versatile material that plays a crucial role in various applications across multiple sectors. Its unique combination of durability, corrosion resistance, and strength makes it a reliable choice for both industrial and everyday uses. Whether you’re in construction, agriculture, or design, the benefits of using galvanized mesh wire are clear. By understanding its features and adhering to proper maintenance practices, users can ensure they get the most out of this remarkable material.

-

Why a Chain Link Fence is the Right Choice

NewsJul.09,2025

-

Upgrade Your Fencing with High-Quality Coated Chicken Wire

NewsJul.09,2025

-

The Power of Fence Post Spikes

NewsJul.09,2025

-

The Best Pet Enclosures for Every Need

NewsJul.09,2025

-

Secure Your Property with Premium Barbed Wire Solutions

NewsJul.09,2025

-

Enhance Your Construction Projects with Quality Gabion Boxes

NewsJul.09,2025

Products categories