Dec . 12, 2024 09:18 Back to list

iron mesh manufacturers

The Role of Iron Mesh Manufacturers in Modern Construction

Iron mesh, also known as wire mesh or welded wire fabric, is a fundamental material used in various construction applications. Its versatility, strength, and durability make it a preferred choice for builders and contractors worldwide. The contribution of iron mesh manufacturers to the construction industry is indispensable, as they provide essential products that enhance structural integrity, improve safety, and optimize costs.

The Importance of Iron Mesh in Construction

Iron mesh serves multiple purposes in construction projects. Primarily, it is used to reinforce concrete, ensuring that structures can withstand significant loads and stresses. When embedded in concrete, iron mesh distributes weight evenly and prevents cracking, enhancing the longevity of buildings, bridges, and other infrastructure.

In addition, iron mesh is utilized in fencing and security applications. It provides a secure barrier while allowing visibility and airflow, making it ideal for both residential and commercial spaces. The aesthetic versatility of iron mesh also allows it to be used creatively in architectural designs, adding both functionality and visual interest to structures.

Types of Iron Mesh Products

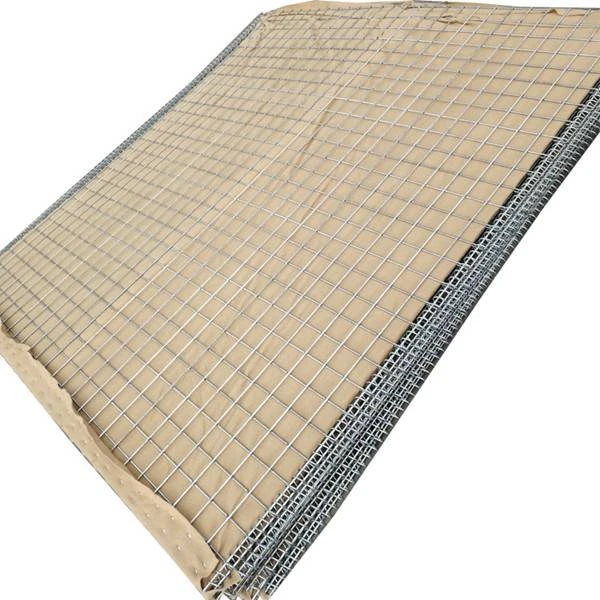

There are several types of iron mesh products available, each designed for specific applications. Manufacturers produce welded wire mesh, which is made by welding intersecting wires together at regular intervals. This type of mesh is commonly used for concrete reinforcement and is available in various gauges and sizes.

Another popular product is expanded metal mesh, which is created by cutting and stretching a flat sheet of metal. This form of iron mesh offers excellent strength-to-weight ratios and is often used in walkways, safety barriers, and architectural facades.

Additionally, manufacturers also provide custom solutions, allowing architects and engineers to design mesh products tailored to their specific project needs. This customization can include modifications in size, shape, and coating to improve corrosion resistance or aesthetic appeal.

iron mesh manufacturers

Manufacturing Process

The manufacturing process of iron mesh involves several key steps. Initially, raw materials such as steel wires are sourced, graded, and prepared for production. The chosen wires undergo a process of cleaning and coating, which can involve galvanization or applying protective paints to prevent rust and increase durability.

Once the materials are ready, they are fed into machines that weld or stretch the wires into the desired mesh configurations. Quality control is critical throughout the manufacturing process to ensure that the finished products meet industry standards for strength and durability. Inspection and testing are conducted before the iron mesh is packaged and shipped to clients in various sectors.

Innovation and Sustainability

In recent years, the iron mesh manufacturing industry has seen significant innovations aimed at improving efficiency and sustainability. The introduction of automated machinery has enhanced production rates and consistency, while new technologies allow for the development of lightweight mesh options without sacrificing strength.

Sustainability is also a pressing concern. Many manufacturers are exploring ways to reduce their environmental footprint through the use of recycled materials and energy-efficient production methods. This commitment to sustainability resonates with modern construction practices that prioritize eco-friendly solutions.

Conclusion

Iron mesh manufacturers play a crucial role in the construction industry by providing reliable and versatile products that underpin the safety and durability of structures. With the ongoing advancements in manufacturing technology and a focus on sustainability, these manufacturers are well-positioned to meet the changing demands of the market. As construction projects become more complex and the need for innovative materials grows, the significance of iron mesh will continue to rise, reinforcing its position as a cornerstone of modern construction.

In conclusion, the impact of iron mesh manufacturers extends beyond the materials they provide; they contribute to the overall advancement of construction practices, ensuring that infrastructure remains robust, secure, and adaptive to human needs. As the industry evolves, so too will the contributions of these manufacturers, shaping the future of construction in an increasingly demanding world.

-

Why a Chain Link Fence is the Right Choice

NewsJul.09,2025

-

Upgrade Your Fencing with High-Quality Coated Chicken Wire

NewsJul.09,2025

-

The Power of Fence Post Spikes

NewsJul.09,2025

-

The Best Pet Enclosures for Every Need

NewsJul.09,2025

-

Secure Your Property with Premium Barbed Wire Solutions

NewsJul.09,2025

-

Enhance Your Construction Projects with Quality Gabion Boxes

NewsJul.09,2025

Products categories