Jul . 29, 2025 21:20 Back to list

High Quality Galvanised Gabion Boxes for Durable Erosion Control

Explore an in-depth analysis on galvanised gabion boxes, buying insights, industry standards, advanced manufacturing technology, and how modern galvanized gabion baskets influence construction, defense, and environmental engineering.

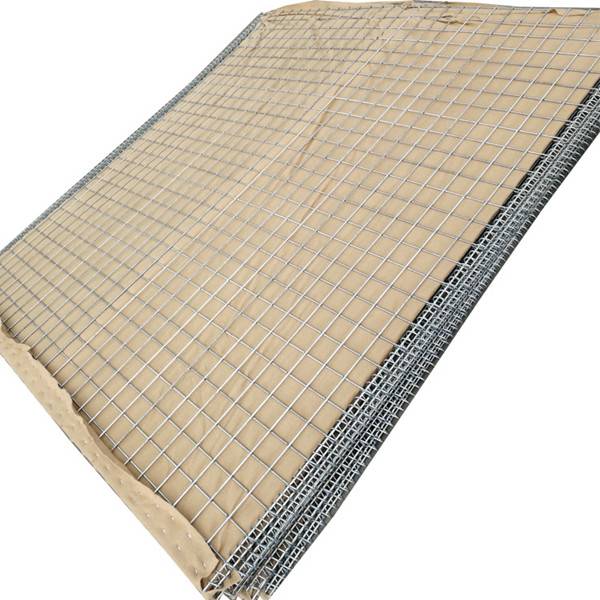

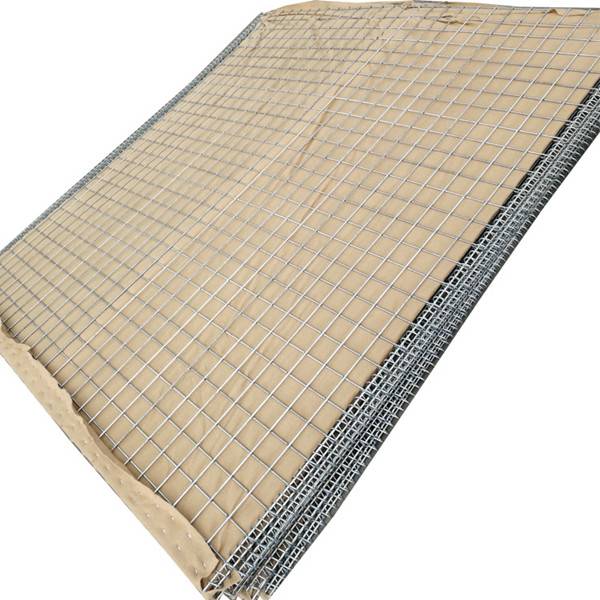

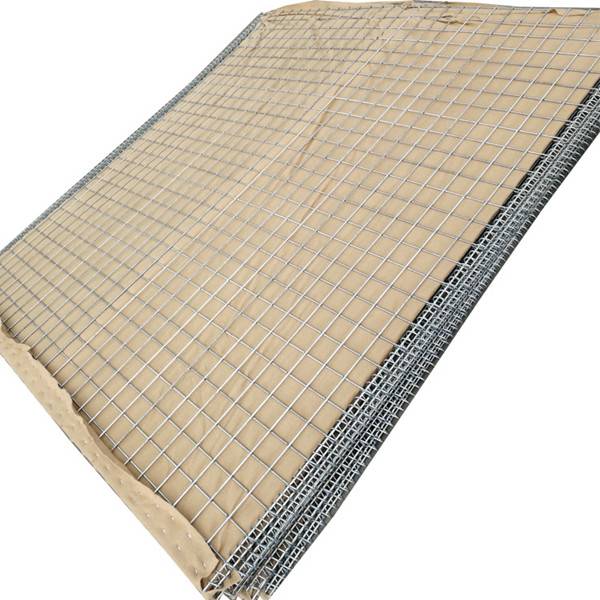

Galvanized Hesco Barrier Welded Gabion Box as robust landscape and security solutions

1. Industry Overview: Why Galvanised Gabion Boxes are Essential

The demand for galvanised gabion boxes, also known as galvanized gabion baskets or galvanized gabion mesh, has grown rapidly in recent years—fueled by surging requirements in military defense barriers, civil engineering, hydraulic works, and environmental landscaping.

Industry forecasts predict a CAGR of 5.8% through 2030 in the global gabion market [Source: ResearchAndMarkets].

Key market drivers include strict erosion control regulations, increased flood defense investments, green landscape design trends, and rising military budget allocations for perimeter fortifications.

Key Applications

- Erosion and Flood Control (riverbanks, truck roads, bridges)

- Military Defense Barriers (perimeter, blast protection)

- Retaining walls in Residential & Infrastructural Projects

- Landscaping & Acoustic Walls

- Coastal & Mining Engineering

2. Manufacturing Process Flow (Step-By-Step with Diagram)

- Material Selection – Choose low-carbon steel wire Q195/Q235/Q345 up to ISO9001:2015 standards for superior strength and ductility.

- Wire Galvanizing – Hot-dip galvanized or Galfan (Zn-Al alloy) coatings for high anti-corrosion, conforming to ISO1461, ASTM A641.

- Mesh Welding/Forming – CNC automatic welding machines form uniform grids; wires welded at each intersection (ANSI/AWS D1.1 weld quality standard).

- Gabion Box Assembly – Panels folded and secured using spirals, C rings, or lacing wire for precise geometry and stability.

- Final Surface Treatment – Additional PVC, powder, or epoxy coating as option for extreme corrosion resistance.

- Quality Inspection – Strict QC per project on mesh aperture, tensile strength, zinc coating, and overall dimension accuracy.

- Packing & Logistics – Unit packing, palletizing, and moisture barrier to ensure gabions arrive in perfect condition.

CNC mesh welding in galvanized gabion baskets production

CNC mesh welding in galvanized gabion baskets production

Manufacturing process: From material to finished galvanised gabion boxes

3. Industry Data & Technical Parameter Table

Technical Parameter Trend Chart

Filled galvanized gabion baskets in urban anti-scour project

4. Product Benchmark: Galvanized Hesco Barrier Welded Gabion Box vs. Other Solutions

The Galvanized Hesco Barrier Welded Gabion Box (see full specs: product link) epitomizes structural innovation, offering safety, speed, and modularity for high-impact engineering and military defense. Below you’ll find an in-depth product comparison and industry data visualization.

| Model/Feature | Galvanized Hesco Barrier | PVC-coated Gabion Box | Traditional Woven Gabion |

|---|---|---|---|

| Production Process | CNC Welded Mesh, Hot-Dip Galvanized | Hexagonal Woven/PVC Coated | Twisted Mesh, Minimal Coating |

| Standard Dimensions | 2.2x1.07x1.0 m / modular | 1x1x1 m / customizable | 1x1x1 m / customizable |

| Tensile Strength | ≥ 350Mpa | 270–340Mpa | 220–320Mpa |

| Anti-Corrosion (years) | 40–50 | 35–45 | 15–28 |

| Setup Speed | Ultra-fast one-touch deployment | Needs manual lacing | Labor-intensive |

| Certifications | ISO1461, ASTM A974 | ISO10223, CE | Basic EN10223 |

| Main Industry Use | Defence, Flood, Perimeter, Dams | Landscaping, Flood Protection | River, Embankment, Retaining Walls |

| Cost Scale (How much does a Hesco barrier cost?) | $32 – $77 per unit | $18 – $42 per unit | $15 – $35 per unit |

Cost Proportion Pie Chart

Cost Insights: "How much does a Hesco barrier cost?"

Generally, the price for military-grade galvanised gabion boxes or Hesco barriers ranges from $32–$77 per unit, depending on mesh size, coating, wire thickness, and order volume.

When compared with traditional gabions, welded army boxes represent a higher initial investment but deliver far greater cost-efficiency with regard to installation speed, reduced labor, and lifespan.

Heavy-duty mesh panels of galvanised gabion boxes, modular for rapid deployment

5. Customization & Solution Engineering

- Wire Gauge Selection: 4.0–6.0mm options for enhanced ballistic or flood resistance (typical for critical defense sites).

- Mesh Geometry: Square (75x75mm), rectangular (50x100mm), or custom apertures according to fill stone size and wall height.

- Surface Coating: Galfan (Zn-5Al-MM) for aggressive marine or chemical environment, with up to 50-year corrosion guarantee (Galfan reference).

- Special shapes and rapid deployment modules (accordion fold, collapsible, multi-compartment units) for on-site speed and space efficiency.

Custom geometry galvanized gabion mesh for complex river training projects

Major Technical Indices Comparison

6. Application Case Studies & Real-World Projects

- Specs: Galfan coated 76.2x76.2mm mesh, 4.0mm wire, modular 2m x 1m x 1m boxes

- Scope: 2,300 units installed as river levee reinforcement, flood wall, and spillway barriers

- Performance: Achieved 35% faster deployment and significant reduction in water seepage vs concrete

- Feedback: Project engineers noted exceptional corrosion performance in aggressive brackish water conditions

- Specs: Hot-dip galvanized, 5.0mm wire, 75x75mm mesh, filled with local limestone aggregate

- Scope: 680 units assembled in 48 hours to form barriers, checkpoints, and blast mitigation zones

- Feedback: Security review showed zero failures under live-fire and extreme rainfall tests (QA certified: ISO9001:2015)

- Operational outcome: 40% labor cost saving compared to sandbagging solution

- Specs: Hot-dip galvanized mesh, 5.0 mm wire, modular 2 x 1 x 1 m gabion units

- Project scale: 1,800 m coastline protected; 200+ units used in critical high wave zone

- Result: Zero rust observed after 5 years in high salt exposure zone (Tested: ISO1461, ASTM B117)

7. Industry Authority, Certifications, and Trust Points

- Certifications: All gabion products manufactured according to ISO 1461 (zinc coating), ISO9001:2015 (factory management), and EN10223-8 standards.

- Global References: Products supplied to Sinopec, Shell, Bechtel, U.S. Army, Dutch Dikes Association

- Quality Assurance: 10-year warranty, full technical and after-sales support, custom engineering reports.

- Compliance: Regular 3rd-party laboratory corrosion and mechanical testing (e.g. TUV, SGS).

8. FAQ – Technical Questions & Professional FAQ

- Q1: What is the difference between hot-dip galvanized and Galfan coating for gabion boxes?

- Hot-dip galvanizing (zinc) offers basic corrosion resistance (25–35 years in moderate environments). Galfan (Zn-5%Al-MM) provides up to 2x life span due to better self-healing at cuts/edges; ideal for marine environments.

- Q2: Which mesh size is standard for galvanized gabion mesh?

- 75x75mm or 76.2x76.2mm square mesh is standard for welded gabions; 50x100mm or 80x100mm available on request—choice depends on fill stone size.

- Q3: What wire tensile strength is specified for military or flood control gabions?

- Minimum 350–400Mpa (per EN 10218/ASTM A974). High tensile wire ensures durability against impact, flood surge, or projectile penetration.

- Q4: Are there international standards for gabion products?

- Yes. Key standards are ISO 10223-8 (gabion mesh), ISO 1461 (zinc coating), ASTM A974, EN10223. Always request certification for your order.

- Q5: What is the minimum order/Typical delivery time?

- Minimum order usually 100 units. Lead time: 7–18 business days depending on specs, quantity, and current production schedule.

- Q6: How do I calculate "how much does a Hesco barrier cost" for a large perimeter?

- Unit price $32–$77 (ex-works); total cost = [unit price] × [number of boxes] + shipping. Custom logo/shapes/extra coating incur additional cost.

- Q7: What warranty/after-sales support is available?

- 10-year manufacturer warranty, technical advice, installation guidance, and free spare parts (as agreed in contract). All support is documented to ISO9001:2015 standards.

9. Project Management & Customer Support

- Lead Time: 7-18 working days (depending on scope & custom features)

- Warranty: 10 years (including post-sales service and technical consultation)

- Support: Full documentation, engineering

-

Custom Weld Mesh – Tailored Solutions for Durable Industrial Fencing & Construction

NewsNov.24,2025

-

Comprehensive Guide to Chicken Welded Wire Mesh: Uses, Benefits & Suppliers

NewsNov.23,2025

-

BRC Weld Mesh – Durable Reinforcement Solutions for Modern Construction

NewsNov.23,2025

-

Durable BRC 3315 Mesh for Reliable Concrete Reinforcement | Hardware In Store

NewsNov.23,2025

-

Discover the Benefits of Green Weld Mesh – Durable, Sustainable Fencing Solutions

NewsNov.22,2025

-

Electro Welded Mesh: Durable, Versatile Steel Grid Solutions | HardwareInStore

NewsNov.22,2025

Products categories