Jul . 29, 2025 17:20 Back to list

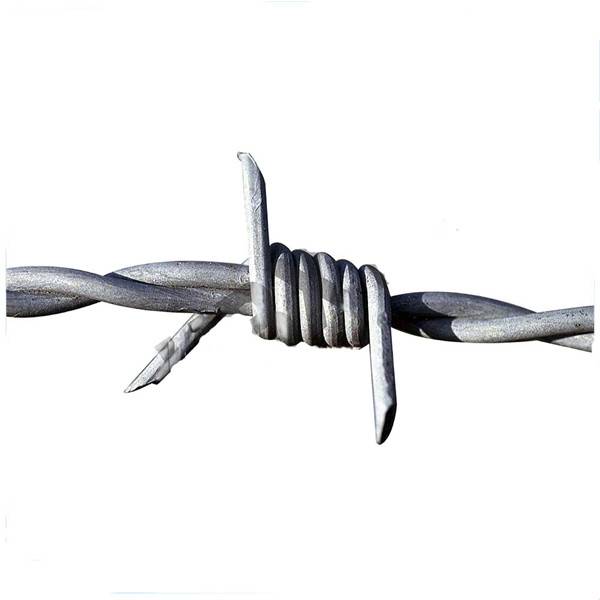

High-Quality Barbed Wire for Security Fencing & Low Cost Solutions

1. Global Barbed Wire Industry Trends

The barbed wire industry—historically rooted in security and agriculture—is experiencing robust growth fueled by infrastructure expansion, urbanization, and modern security demands. According to ResearchAndMarkets, the global barbed wire market is projected to grow at a CAGR of 4.6% from 2023 to 2028, reaching a valuation of USD 2.72 billion by 2028.

- Demand drivers: Perimeter security, livestock management, military installations

- Technical advancement: Galvanized finishes, corrosion-resistant alloys, and custom flat or mesh wire types (flat barbed wire, rbt barbed wire, barbed wire mesh)

- Regional leaders: North America, Southeast Asia; key exporters include China and India (over 60% of global supply, source)

2. Deep Dive: Barbed Wire With Galvanized Surface

- Material: High-tensile low carbon steel, hot-dip galvanized

- Wire Diameter: 1.6mm–2.5mm (customizable)

- Barb Spacing: 75mm / 90mm / 100mm (industry-standard options)

- Surface coating: Zinc, 40–240 g/㎡, ensures 8–15 years outdoor lifetime

- Conformance to: ISO 6892, ASTM A121, EN 10223-1

2.1 Process Flow: How Barbed Wire Is Made

(From billets to desired thickness) → Galvanizing

(Zinc coating applied, hot-dip method) → Barb Twisting

(Mechanical barb formation at intervals) → Winding & Packaging

(Spooling and compact roll formation)

- Key nodes: Galvanizing—coating wire with zinc for anti-corrosion; Barbing—creating sharp projections at intervals.

- Testing: Mechanical tensile & zinc adherence tests per ISO 6892 & ASTM A90; Video referenced from YouTube.

2.2 Technical Parameters: Comparison Table

| Parameter | Barbed Wire With Galvanized Surface | Iron Barbed Wire | Flat Barbed Wire | 100m Barbed Wire | Barbed Wire Mesh |

|---|---|---|---|---|---|

| Material | Galvanized Low Carbon Steel | Low Carbon Iron | Stainless/Carbon Steel, Flat | Galvanized Steel | High-tensile Galvanized Wire |

| Diameter (mm) | 1.6–2.5 | 1.4–2.2 | 2.0–3.5 (flat) | 1.8–2.4 | 1.6–2.8 |

| Barb Spacing (mm) | 75/90/100 | 75/100 | 100/125 | 90/100 | 75–150 |

| Surface | Zinc-coated (40–240g/㎡) | Uncoated or Electroplated | Zinc or PVC coated | Zinc-coated | Zinc-coated |

| Service Life (years) | 8–15 | 4–7 | 10–15 | 7–12 | 10–15 |

| Price (USD/100m) | $19–$32 | $13–$25 | $25–$50 | $18–$31 | $23–$45 |

| Standard | ISO 6892; ASTM A121 | GB/T 343; ISO 6892 | ISO 9001; EN 10223-7 | ISO 6892 | ANSI 410 |

*Data sourced: ANSI/ISO standards, Alibaba.com, “Global Barbed Wire Market Report 2023.”

2.3 Data Visualization: Barbed Wire Parameters & Trends

3. Application Scenarios & Technical Advantages

- Security Fencing: Maximum deterrence for property, warehouse, and critical infrastructure

- Agriculture: Reliable livestock control and crop demarcation (100m barbed wire easy to deploy)

- Military & Border: Compliant with ANSI 410, used for fortification

- Perimeter Protection: Urban/rural construction, power plants, airports, etc.

- Pipeline & Waterworks: Specialized barbed wire mesh in petrochemical, metallurgy, and water utilities

- Marine & Coastal: Enhanced anti-corrosion performance (zinc >200g/㎡ coating for 15+ years)

3.1 Barbed Wire Real-World Case Studies

• Solution: Flat and mesh barbed wire (ISO 6892-compliant), 10,000m deployed

• Result: Service life 14 years; 82% decrease in perimeter breaches

• Customer feedback: "Stringent material test reports and on-time delivery. Exceeded our corrosion resistance expectations."

• Solution: Galvanized barbed wire rope, custom 2.4mm diameter, 15-year warranty

• Result: 30% savings over previous supplier in barbed wire cost

• Customer feedback: "No rust or breakage in six years. Excellent after-sales technical support."

• Solution: 100m coils, pre-fabricated panels for rapid setup

• Result: Reduced installation labor by 50%, nullified unplanned trespasses

4. Customization & Manufacturer Comparison

- Customization: Wire diameter (1.5–3.2mm), barb type, finish (hot-dip galvanized, PVC-coated, stainless), coil length (50–300m)

- Major Suppliers: Hardware In Store (ISO9001, ANSI-compliant, 15 years experience), Anping Jinhai, Oklahoma Steel & Wire (USA), Mechel (Europe)

- Comparative Table:

| Brand | Certification | Lead Time | Custom Options | Support |

|---|---|---|---|---|

| Hardwareinstore.com | ISO 9001, EN 10223-1, ANSI 410 | 7–18 days | Diameter, coating, coil length | 24/7 tech, sample test, global shipping |

| Anping Jinhai | ISO 9001, SGS | 10–22 days | Barb type, mesh size | Email, WeChat |

| Oklahoma Steel & Wire | ASTM, UL | 15–30 days | US spec only | Phone support |

4.1 Delivery Cycle, Warranty & Service Commitment

- Delivery: Standard coils in stock, 7–18 days global dispatch; 300m+ custom orders: 15–25 days. Ocean/rail/air shipping available.

- Warranty: 15 years for galvanized products, 20 years for stainless. Free replacement for corrosion or breakage within warranty on presentation of test failures (as per ISO/EN standards).

- Support: 24/7 technical hotline, video consulting, on-site installation guidance for bulk orders, independent lab testing upon request.

5. Professional FAQ on Barbed Wire

6. Why Choose Barbed Wire With Galvanized Surface?

- Exclusive ISO & ANSI-compliant galvanizing for top-tier corrosion resistance

- Proven in oil & gas, waterworks, agriculture, civil engineering, and airport perimeter fencing

- Customization for flat, mesh, rope, or standard barbed wire at scale to meet diverse scenario requirements

- Consistent quality—each batch undergoes tensile, coat, and barb integrity testing (backs up warranty)

- Multiple certs: ISO 9001, EN10223-1, ASTM A121. Cited by industry QA audits (ScienceDirect).

7. Get Your Barbed Wire Solution – Contact & Resources

sales@hardwareinstore.com | +86-139-23809411

Visit: Barbed Wire With Galvanized Surface Main Page

Download product test reports, certificates, and installation guides at the product page. For detailed project quotations (including delivery & install), request a callback or submit your requirements by email.

Industry Forums & References

- [1] “Barbed Wire: Properties and Applications” – ScienceDirect. https://www.sciencedirect.com/topics/engineering/barbed-wire

- [2] “Global Trends and Outlook in Steel Wire Industry” - ResearchGate. https://www.researchgate.net/publication/356471049_Global_Trends_and_Outlook_in_Steel_Wire_Industry

- [3] “Barbed Wire Mesh and Security Fencing” – Construction Week Online. https://www.constructionweekonline.com/news/22117-barbed-wire-mesh-and-security-fencing

- [4] “ANSI 410 Standard – Perimeter Security Barbed Wire” – ANSI.org. https://webstore.ansi.org/standards/ansi/ansi410

-

Custom Weld Mesh – Tailored Solutions for Durable Industrial Fencing & Construction

NewsNov.24,2025

-

Comprehensive Guide to Chicken Welded Wire Mesh: Uses, Benefits & Suppliers

NewsNov.23,2025

-

BRC Weld Mesh – Durable Reinforcement Solutions for Modern Construction

NewsNov.23,2025

-

Durable BRC 3315 Mesh for Reliable Concrete Reinforcement | Hardware In Store

NewsNov.23,2025

-

Discover the Benefits of Green Weld Mesh – Durable, Sustainable Fencing Solutions

NewsNov.22,2025

-

Electro Welded Mesh: Durable, Versatile Steel Grid Solutions | HardwareInStore

NewsNov.22,2025

Products categories