Jan . 14, 2025 09:45 Back to list

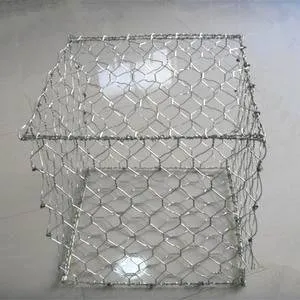

hexagonal wire mesh sizes

Hexagonal wire mesh, often referred to as chicken wire, is a versatile material known for its durability and flexibility. Its applications range from securing livestock and poultry to providing support in construction and gardening. With a variety of mesh sizes available, choosing the right one depends on the intended use and the specific requirements of a project. Understanding these mesh sizes can enhance the effectiveness and longevity of a project, whether for industrial, commercial, or domestic purposes.

One major consideration is the coating of the wire mesh. Galvanized before weaving (GBW) or galvanized after weaving (GAW) are commonly available coated options. GAW involves the mesh being woven first and then dipped into a bath of molten zinc, providing superior rust and corrosion protection compared to GBW, where the wire is galvanized prior to the weaving process. Choosing the right coating, based on environmental exposure, ensures the mesh maintains its integrity over time. For agricultural use, hexagonal wire mesh proves indispensable. The right mesh size can serve as an effective containment solution for poultry and small livestock, reducing loss and preventing escape. Additionally, it serves to protect crops from birds and smaller animals that can cause significant damage, thereby safeguarding investment. In construction, it reinforces concrete in cement structures, functioning as a reliable framework that aids in reducing cracking and maintaining structural integrity. Whether it's a small-scale backyard project or a large commercial endeavor, considering these attributes is essential for optimizing the health and longevity of the undertaking. Ultimately, the intrinsic qualities of hexagonal wire mesh make it indispensable across a variety of industries. Selecting the appropriate size, gauge, and coating based on specific project requirements can significantly impact performance and durability. By understanding these facets, you can ensure that the mesh provides the necessary functionality and longevity needed in each unique application. Whether for containment, protection, or reinforcement, the strategic use of hexagonal wire mesh is a testament to its enduring utility and versatility.

One major consideration is the coating of the wire mesh. Galvanized before weaving (GBW) or galvanized after weaving (GAW) are commonly available coated options. GAW involves the mesh being woven first and then dipped into a bath of molten zinc, providing superior rust and corrosion protection compared to GBW, where the wire is galvanized prior to the weaving process. Choosing the right coating, based on environmental exposure, ensures the mesh maintains its integrity over time. For agricultural use, hexagonal wire mesh proves indispensable. The right mesh size can serve as an effective containment solution for poultry and small livestock, reducing loss and preventing escape. Additionally, it serves to protect crops from birds and smaller animals that can cause significant damage, thereby safeguarding investment. In construction, it reinforces concrete in cement structures, functioning as a reliable framework that aids in reducing cracking and maintaining structural integrity. Whether it's a small-scale backyard project or a large commercial endeavor, considering these attributes is essential for optimizing the health and longevity of the undertaking. Ultimately, the intrinsic qualities of hexagonal wire mesh make it indispensable across a variety of industries. Selecting the appropriate size, gauge, and coating based on specific project requirements can significantly impact performance and durability. By understanding these facets, you can ensure that the mesh provides the necessary functionality and longevity needed in each unique application. Whether for containment, protection, or reinforcement, the strategic use of hexagonal wire mesh is a testament to its enduring utility and versatility.

Pervious:

Latest news

-

Why a Chain Link Fence is the Right Choice

NewsJul.09,2025

-

Upgrade Your Fencing with High-Quality Coated Chicken Wire

NewsJul.09,2025

-

The Power of Fence Post Spikes

NewsJul.09,2025

-

The Best Pet Enclosures for Every Need

NewsJul.09,2025

-

Secure Your Property with Premium Barbed Wire Solutions

NewsJul.09,2025

-

Enhance Your Construction Projects with Quality Gabion Boxes

NewsJul.09,2025

Products categories

NEED HELP?

Don' t Hesitate To Contact Us For More Information About Company Or Service

CONTACT US