Oct . 14, 2025 15:43 Back to list

Heavy Gauge Wire Mesh: A robust barrier and load-bearing core in the industrial field

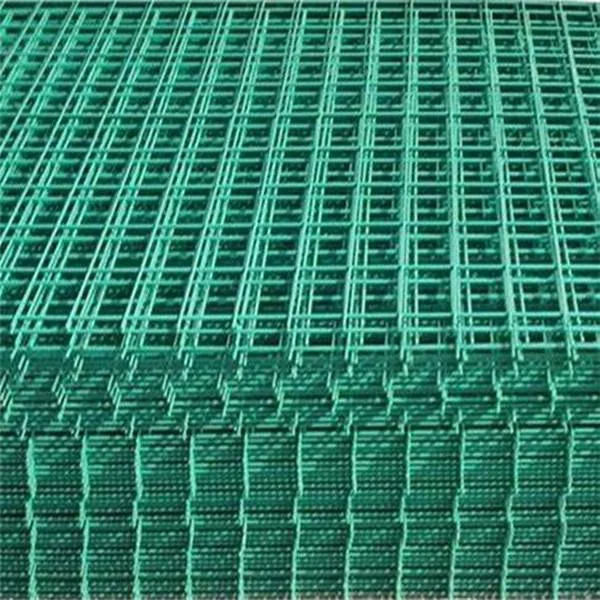

In many industrial production scenarios, Heavy Gauge Wire Mesh has become a reliable partner for various heavy-duty operations due to its strong load-bearing capacity and durability. It is different from the lightness of ordinary wire mesh, and with its special material and structural design, it demonstrates irreplaceable value in harsh environments.

The material and structure of Heavy Gauge Wire Mesh are the foundation of its powerful performance

In terms of material, high-strength steels such as high carbon steel and manganese steel are often used, and some special scenarios may also use alloy materials. After high-temperature forging and special heat treatment, the tensile and impact resistance are greatly improved. Structural design emphasizes stability, and common processes include cross weaving of warp and weft, stamping and stretching forming, etc. The mesh woven by crossing warp and weft can have a thickness of several millimeters, and the intersection points are reinforced by welding or locking processes to form a tight and firm grid; The wire mesh formed by stamping and stretching is punched with regular hole patterns through molds, which have stronger overall rigidity and can withstand greater pressure.

The performance advantages of Heavy Gauge Wire Mesh are particularly significant in extreme environments

The load-bearing capacity of wire fabric mesh is astonishing, capable of withstanding several tons or even tens of tons per square meter, and performs well in scenarios such as heavy equipment support and material carrying. At the same time, it has excellent corrosion resistance and wear resistance. After surface treatment such as galvanizing and coating, it can resist the erosion of harsh environments such as acid and alkali, high temperature, and humidity, and its service life can reach decades. In addition, its good breathability and permeability allow it to efficiently intercept heavy impurities without causing blockages.

The application of Heavy Gauge Wire Mesh covers multiple industrial heavy sectors

In mining, welded chicken wire is used as a vibrating screen to screen large ores and crushed stones, and withstand high-strength material impacts; In construction engineering, as a substitute or supplement to steel mesh, it is used for concrete pouring to enhance the crack resistance and load-bearing capacity of structures; At the port terminal, it serves as a protective net and barrier to prevent heavy objects from falling and illegal entry; In the field of environmental protection, it is used for heavy impurity filtration in sewage treatment and anti-seepage isolation in landfills.

Technological innovation continuously expands the application boundaries of Heavy Gauge Wire Mesh

The development of a new composite welded wire chicken pen material makes the wire mesh lighter while maintaining high strength, reducing installation and transportation costs; The intelligent production process enables precise customization of mesh size and structure to meet personalized needs in different scenarios; The introduction of 3D weaving technology enhances the overall stability of the wire mesh, enabling it to cope with more complex stress situations.

In summary, heavy duty welded wire has become an indispensable key material in the industrial field due to its high-strength material, stable structure, excellent performance, and wide range of applications. From mines to buildings, from ports to environmental protection, it safeguards the safety and efficiency of various heavy operations with its sturdy and reliable characteristics. With the continuous advancement of technology, Heavy Gauge Wire Mesh will undoubtedly play an important role in more emerging fields, providing solid support for industrial development.

Heavy Gauge Wire Mesh FAQs

What are the specific applications of Heavy Gauge Wire Mesh in the construction industry?

Heavy Gauge Wire Mesh is often used for building reinforcement, foundation support, and concrete structure reinforcement due to its high strength and durability. For example, in large-scale infrastructure projects, it can serve as a substitute for steel bars, effectively dispersing loads and preventing cracking. In addition, in tunnel engineering or slope protection, Heavy Gauge Wire Mesh can also play a role in stabilizing soil. Have you ever encountered a scenario where you need to choose this type of material?

How to distinguish between Heavy Gauge Wire Mesh and ordinary steel wire mesh?

Heavy Gauge Wire Mesh typically uses thicker wire diameters (such as 6mm or more) and larger mesh spacing. The material is mostly high carbon steel or stainless steel, which has higher tensile strength and load-bearing capacity. Ordinary steel wire mesh is mostly used for lightweight fences or decorations, with finer wire diameters. Do you pay attention to these parameters when making a purchase?

What are the anti-corrosion treatment methods for Heavy Gauge Wire Mesh?

Common anti-corrosion processes include hot-dip galvanizing, galvanizing, PVC coating, or spraying epoxy resin. Hot dip galvanizing is suitable for long-term rust prevention outdoors, while PVC coating can balance aesthetics and corrosion resistance. Which treatment method would you prefer in coastal or high humidity environments?

Why is Heavy Gauge Wire Mesh frequently used in mining operations?

In mining operations, Heavy Gauge Wire Mesh is used for screening ores, reinforcing tunnels, or making mining screening baskets. Its wear resistance and impact resistance can withstand harsh environments. For example, it can effectively filter large pieces of material on a vibrating screen. Do you think this type of scenario requires customized mesh design?

What technical details should be paid attention to when installing Heavy Gauge Wire Mesh?

During installation, it is necessary to ensure that the grid is flat and tight, and high-strength bolts or welding should be used for fixation to avoid uneven local stress. For large-scale installations (such as industrial platforms), expansion joints should also be reserved to prevent thermal expansion and contraction deformation. Have you encountered any problems during construction due to improper installation?

-

Custom Weld Mesh – Tailored Solutions for Durable Industrial Fencing & Construction

NewsNov.24,2025

-

Comprehensive Guide to Chicken Welded Wire Mesh: Uses, Benefits & Suppliers

NewsNov.23,2025

-

BRC Weld Mesh – Durable Reinforcement Solutions for Modern Construction

NewsNov.23,2025

-

Durable BRC 3315 Mesh for Reliable Concrete Reinforcement | Hardware In Store

NewsNov.23,2025

-

Discover the Benefits of Green Weld Mesh – Durable, Sustainable Fencing Solutions

NewsNov.22,2025

-

Electro Welded Mesh: Durable, Versatile Steel Grid Solutions | HardwareInStore

NewsNov.22,2025

Products categories