Jan . 17, 2025 01:00 Back to list

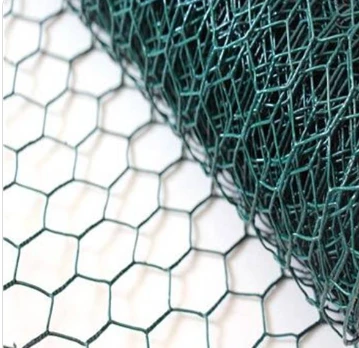

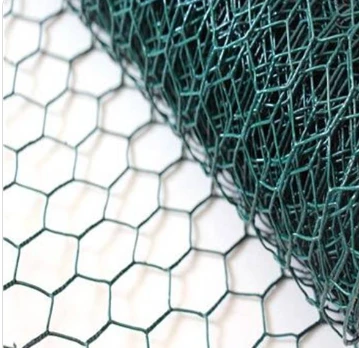

galvanized poultry netting

Galvanized poultry netting, an essential fixture in modern agriculture and poultry management, stands out as a multipurpose solution tailored to ensure the safe and efficient containment of poultry. Its widespread use underscores the combination of traditional craftsmanship and modern technological enhancements. Through the lens of real-world experience and technical expertise, galvanized poultry netting emerges as a superior choice for poultry enthusiasts and professional farmers alike.

Professional insights further emphasize the importance of proper netting selection based on specific farm needs. Experts recommend considering factors such as mesh size, wire gauge, and height to ensure optimal performance. For example, smaller mesh sizes are ideal for keeping young chicks safe, while larger mesh sizes suit adult birds. Investing time in selecting the correct type of netting correlates directly with animal safety and ease of management. Trustworthiness in this context is reinforced by the industry’s trust in galvanized poultry netting as a standard. Its longstanding use in agriculture acts as a testament to its effectiveness and reliability. By prioritizing customer satisfaction and product longevity, those opting for galvanized poultry netting are making an informed choice towards sustained farm productivity. Certified suppliers further bolster trust by adhering to stringent manufacturing processes that ensure consistent product quality. Moreover, galvanized poultry netting aligns with eco-conscious practices. Its durability reduces waste by minimizing the frequency of replacements required, thereby leading to lesser resource utilization. The zinc coating, applied through environmentally aware processes, underscores a commitment to sustainability while maintaining product excellence. In summary, galvanized poultry netting represents a fusion of traditional methods with cutting-edge advancements, offering unmatched resilience, versatility, and trustworthiness. Whether for a novice poultry keeper or an established agricultural practitioner, it provides an assured investment that safeguards poultry and enhances the efficiency of farming operations. The continued endorsements from both end-users and professionals solidify its status as the premier choice, making it an invaluable component in the agricultural toolkit.

Professional insights further emphasize the importance of proper netting selection based on specific farm needs. Experts recommend considering factors such as mesh size, wire gauge, and height to ensure optimal performance. For example, smaller mesh sizes are ideal for keeping young chicks safe, while larger mesh sizes suit adult birds. Investing time in selecting the correct type of netting correlates directly with animal safety and ease of management. Trustworthiness in this context is reinforced by the industry’s trust in galvanized poultry netting as a standard. Its longstanding use in agriculture acts as a testament to its effectiveness and reliability. By prioritizing customer satisfaction and product longevity, those opting for galvanized poultry netting are making an informed choice towards sustained farm productivity. Certified suppliers further bolster trust by adhering to stringent manufacturing processes that ensure consistent product quality. Moreover, galvanized poultry netting aligns with eco-conscious practices. Its durability reduces waste by minimizing the frequency of replacements required, thereby leading to lesser resource utilization. The zinc coating, applied through environmentally aware processes, underscores a commitment to sustainability while maintaining product excellence. In summary, galvanized poultry netting represents a fusion of traditional methods with cutting-edge advancements, offering unmatched resilience, versatility, and trustworthiness. Whether for a novice poultry keeper or an established agricultural practitioner, it provides an assured investment that safeguards poultry and enhances the efficiency of farming operations. The continued endorsements from both end-users and professionals solidify its status as the premier choice, making it an invaluable component in the agricultural toolkit.

Pervious:

Next:

Latest news

-

Why a Chain Link Fence is the Right Choice

NewsJul.09,2025

-

Upgrade Your Fencing with High-Quality Coated Chicken Wire

NewsJul.09,2025

-

The Power of Fence Post Spikes

NewsJul.09,2025

-

The Best Pet Enclosures for Every Need

NewsJul.09,2025

-

Secure Your Property with Premium Barbed Wire Solutions

NewsJul.09,2025

-

Enhance Your Construction Projects with Quality Gabion Boxes

NewsJul.09,2025

Products categories

NEED HELP?

Don' t Hesitate To Contact Us For More Information About Company Or Service

CONTACT US