Aug . 09, 2025 04:40 Back to list

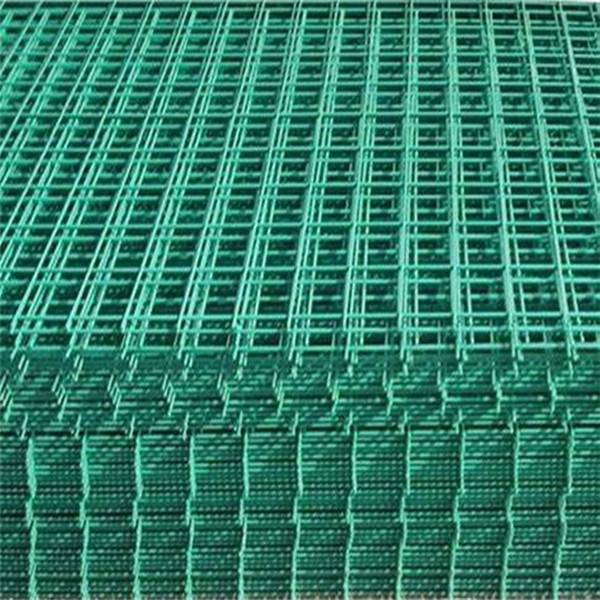

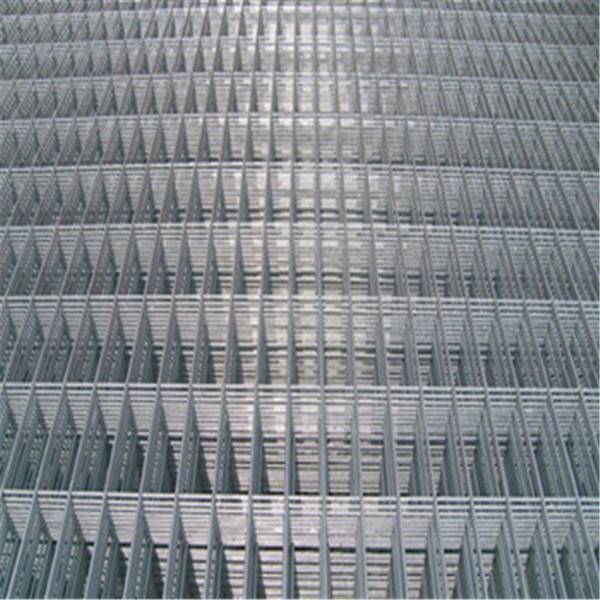

Galvanized Welded Wire Mesh Panels | 2x2, 4x4, 6x6 Options

In the vast landscape of industrial and residential applications, the demand for durable, versatile, and cost-effective material solutions remains constant. Among these, the galvanized welded wire mesh panel stands out as a fundamental component, offering superior strength and corrosion resistance. This comprehensive guide delves into the intricate world of galvanized welded wire mesh panel products, exploring their technological sophistication, diverse applications, and the critical factors that contribute to their unparalleled performance and market relevance. We aim to provide an in-depth understanding, from manufacturing processes to real-world applications, ensuring readers gain expert insights into this essential material.

Industry Trends and Market Dynamics of Galvanized Welded Wire Mesh Panels

The global market for galvanized welded wire mesh panel is experiencing robust growth, driven by burgeoning construction activities, increasing demand for security fencing, and expansion in agricultural and industrial sectors. Recent market analyses indicate a compound annual growth rate (CAGR) steadily rising, reflecting sustained investment in infrastructure development worldwide. Key trends influencing this market include:

- Sustainable Manufacturing Practices: Growing emphasis on eco-friendly production methods, including reduced energy consumption and recyclable materials, is shaping industry standards.

- Technological Advancements: Innovations in welding techniques, automation, and galvanization processes are leading to higher quality, more uniform panels with extended lifespans.

- Diversification of Applications: Beyond traditional fencing and construction, galvanized welded wire mesh panel is finding new niches in architectural design, green infrastructure (e.g., gabions for erosion control), and specialized industrial enclosures.

- Supply Chain Resilience: The industry is adapting to global supply chain challenges by diversifying sourcing and localizing production where feasible, ensuring consistent availability of products like 2x2 galvanized welded wire mesh panel and 4x4 galvanized wire mesh.

According to a report by Grand View Research, the global wire mesh market size was valued at USD 52.7 billion in 2022 and is expected to expand at a CAGR of 5.1% from 2023 to 2030, with galvanized welded wire mesh panel forming a significant segment due to its corrosion resistance and versatility. This growth underscores the material's critical role in modern infrastructure and security solutions.

Technical Parameters and Specifications

Understanding the technical specifications of a galvanized welded wire mesh panel is crucial for selecting the right product for a specific application. These parameters dictate the panel's strength, durability, and suitability for various environmental conditions. Key specifications include:

- Wire Gauge (Diameter): Measured in SWG (Standard Wire Gauge) or millimeters, it determines the panel's robustness. Common gauges range from 1/8 inch (approximately 10 SWG) for lighter applications to thicker gauges for heavy-duty uses like reinforcement. For instance, 1 8 galvanized wire mesh refers to a wire diameter of approximately 1/8 inch (3.175mm), offering significant strength.

- Mesh Opening Size: The distance between the wires, creating square or rectangular openings. Popular sizes include 2x2 galvanized wire mesh (2 inches by 2 inches) ideal for animal enclosures, and 4x4 galvanized wire mesh (4 inches by 4 inches) often used in fencing or concrete reinforcement. Larger openings like 6x6 galvanized wire mesh are common for precast concrete applications.

- Panel Dimensions: Standard panel sizes vary, but custom dimensions are frequently available. Common widths are 3ft, 4ft, 5ft, and 6ft, with lengths ranging from 8ft to 20ft or more.

- Galvanization Type:

- Hot-Dip Galvanized (HDG): Wires are welded first, and then the entire panel is submerged in molten zinc. This creates a thick, highly durable zinc coating, offering superior corrosion resistance, ideal for outdoor and harsh environments. The zinc layer typically ranges from 45 µm to 85 µm (micrometers).

- Electro-Galvanized (EG): Wires are galvanized before welding. This results in a thinner, more uniform zinc coating (typically 10 µm to 30 µm) and a brighter finish, often preferred for aesthetic purposes or less aggressive environments. The welded spots might be less protected if the process isn't optimized.

- Tensile Strength: The maximum stress the wire can withstand before breaking, typically measured in MPa (Megapascals) or PSI (Pounds per Square Inch). For mild steel, this can range from 480-550 MPa (70,000-80,000 PSI).

- Zinc Coating Weight: Measured in g/m² (grams per square meter), indicating the amount of zinc applied. Higher coating weights translate to better corrosion protection and longer service life. For HDG, coating weights typically exceed 300 g/m² per side according to ASTM A123/A123M standards.

Typical Specifications for Galvanized Welded Wire Mesh Panels

The following table provides a general overview of common specifications for galvanized welded wire mesh panel products, often sought after in various industries:

| Characteristic | Common Range/Description | Standard Applications |

|---|---|---|

| Wire Diameter (Gauge) | 1.5 mm - 6.0 mm (approx. 16 SWG - 4 SWG) | 1.5-2.5mm for light fencing/cages; 3.0-4.0mm for general security/reinforcement; 5.0-6.0mm for heavy-duty/structural. |

| Mesh Opening Size | 1"x1" (25.4x25.4mm) to 6"x6" (152.4x152.4mm) | 2x2 galvanized wire mesh panel for animal enclosures; 4x4 galvanized wire mesh for general fencing; 6x6 galvanized wire mesh for concrete reinforcement. |

| Panel Width | 0.9 m - 2.4 m (3 ft - 8 ft) | Standard fencing, architectural panels. |

| Panel Length | 1.8 m - 6.0 m (6 ft - 20 ft) | Construction, security barriers, gabion facing. |

| Galvanization Type | Hot-Dip Galvanized After Weld (HDGAW) or Electro-Galvanized (EGAW) | HDGAW for maximum corrosion resistance (outdoor, industrial); EGAW for aesthetics, lighter duty (indoor, residential). |

| Zinc Coating Weight (HDGAW) | >275 g/m² (ASTM A123/A123M for general products) | Ensures extended lifespan in harsh environments; critical for preventing rust. |

| Material Standard | Low Carbon Steel (ASTM A82/A185 for wire, ASTM A123/A123M for galvanization) | Ensures material quality, weldability, and coating adhesion. |

| Tensile Strength | 480-550 MPa (70-80 ksi) for wires | Indicates the panel's ability to withstand pulling forces without breaking. |

Manufacturing Process of Galvanized Welded Wire Mesh Panel

The production of a high-quality galvanized welded wire mesh panel is a multi-stage process that requires precision engineering and stringent quality control. The primary material is typically low-carbon steel wire, chosen for its excellent ductility and weldability. Below is a detailed breakdown of the manufacturing process, highlighting key stages:

1. Raw Material Procurement and Preparation

- Wire Rod Selection: High-grade low-carbon steel wire rods (e.g., SAE 1006, SAE 1008) are sourced. The chemical composition is critical for ensuring proper tensile strength and ductility.

- Wire Drawing: The wire rods are drawn through a series of dies to reduce their diameter to the desired wire gauge (e.g., for 1 8 galvanized wire mesh or a finer 2x2 galvanized wire mesh panel). This process also work-hardens the steel, increasing its strength.

- Cleaning: Wires are thoroughly cleaned to remove scale, rust, and lubricants. This often involves pickling in acid baths followed by rinsing and drying, crucial for optimal welding and galvanization adhesion.

2. Automated Welding

- Precision Welding Machine: Cleaned wires are fed into a large, automated welding machine. Longitudinal (line) wires are continuously unspooled, while cross (shunt) wires are fed perpendicularly at precise intervals.

- Resistance Spot Welding: At each intersection, powerful electrical currents are passed through the wires, generating intense heat and pressure. This fuses the wires together, forming strong, consistent spot welds. The machine is programmed to create specific mesh opening sizes, such as 4x4 galvanized wire mesh or 6x6 galvanized wire mesh, ensuring uniformity across the panel.

- Quality Check (Post-Weld): After welding, panels undergo an initial inspection to check for any missed welds, weak spots, or incorrect mesh dimensions.

3. Galvanization Process (Hot-Dip Galvanizing After Weld - HDGAW)

For superior corrosion resistance, the most common and effective method is Hot-Dip Galvanizing After Welding (HDGAW). This process ensures that every part of the panel, including the weld points, is thoroughly coated.

- Pre-treatment:

- Degreasing: Panels are immersed in an alkaline solution to remove oils, grease, and dirt.

- Rinsing: Clean water rinses remove residual degreasing solution.

- Pickling: Panels are submerged in hydrochloric or sulfuric acid to remove rust and mill scale, preparing the steel surface for zinc adhesion.

- Rinsing (again): To remove acid residues.

- Fluxing: The panels are dipped into a flux solution (typically zinc ammonium chloride). This prevents oxidation of the clean steel surface before galvanizing and promotes the wetting of the steel by the molten zinc, ensuring a uniform coating.

- Hot-Dip Galvanizing: The prepared welded wire mesh panel is fully immersed in a bath of molten zinc (typically maintained at 450-460°C or 840-860°F). The iron in the steel metallurgically reacts with the molten zinc to form a series of zinc-iron alloy layers, topped by a pure zinc layer. This bond is extremely strong and integral to the steel itself.

- Cooling and Finishing: After withdrawal from the zinc bath, the panels are cooled, often in water, to solidify the coating. Excess zinc is drained off. The panels are then inspected for coating uniformity, thickness, and adherence.

Note on Electro-Galvanizing: While less common for panels due to inferior corrosion protection, electro-galvanizing involves electroplating zinc onto the wires before welding. This results in a thinner coating and potential bare spots at weld points, reducing overall corrosion resistance compared to HDGAW. However, it offers a brighter finish and lower cost.

4. Quality Control and Inspection Standards

Throughout the manufacturing process, rigorous quality control measures are implemented to ensure the galvanized welded wire mesh panel meets specified industry standards. These include:

- Material Certification: Ensuring raw steel wire conforms to ASTM A82 or equivalent standards for cold-drawn steel wire.

- Dimensional Accuracy: Verifying wire diameter, mesh opening size, and panel dimensions (e.g., ensuring a precise 2x2 galvanized welded wire mesh panel).

- Weld Integrity: Destructive and non-destructive testing (e.g., shear strength tests) to confirm the strength of each weld. According to ASTM A185/A185M, the shear strength of welded intersections is a critical parameter.

- Galvanization Coating Thickness and Adhesion: Using magnetic gauges (for thickness) and hammer tests (for adhesion) to ensure the zinc coating meets standards like ISO 1461, ASTM A123/A123M, or AS/NZS 4680.

- Visual Inspection: Checking for surface defects, dross inclusions, or uncoated areas.

Compliance with international standards such as ISO 9001 for quality management systems further ensures consistent product quality and traceability. The typical lifespan of a properly hot-dip galvanized panel can exceed 50 years in many environments, thanks to the robust zinc coating protecting against rust and corrosion, even in demanding conditions prevalent in petrochemical, metallurgy, and wastewater treatment industries.

Technical Advantages of Galvanized Welded Wire Mesh Panels

The combination of welding precision and the galvanization process endows galvanized welded wire mesh panel with distinct advantages over other materials and mesh types:

- Superior Corrosion Resistance: Hot-dip galvanization provides a robust, sacrificial zinc coating that protects the underlying steel from rust and corrosion, even when scratched. This makes them ideal for outdoor and corrosive environments (e.g., coastal areas, industrial zones). Compared to PVC-coated or painted mesh, galvanization offers long-term, self-healing protection.

- High Strength-to-Weight Ratio: Welded intersections provide exceptional rigidity and structural integrity, making the panels strong yet relatively lightweight. This simplifies handling and installation while ensuring durability.

- Versatility and Customization: Available in a wide range of wire gauges (1 8 galvanized wire mesh, etc.) and mesh opening sizes (2x2 galvanized wire mesh panel, 4x4 galvanized wire mesh, 6x6 galvanized wire mesh), these panels can be customized for specific applications, from light animal enclosures to heavy-duty security barriers and concrete reinforcement.

- Ease of Installation and Fabrication: Panels are rigid and hold their shape well, making them easy to cut, bend, and secure using standard tools and fasteners. This reduces installation time and labor costs.

- Low Maintenance and Long Lifespan: Due to their excellent corrosion resistance, galvanized welded wire mesh panel require minimal maintenance, eliminating the need for frequent painting or treatment. This translates to significant cost savings over their extended service life, often exceeding 30-50 years in typical atmospheric conditions.

- Cost-Effectiveness: While the initial cost might be slightly higher than plain steel mesh, the long-term benefits of corrosion protection, reduced maintenance, and extended lifespan make galvanized panels a highly economical choice.

- Aesthetic Appeal: The uniform gray finish of hot-dip galvanized panels can offer a clean, industrial aesthetic, suitable for various architectural and landscape designs.

Manufacturer Comparison: Choosing the Right Partner

When sourcing galvanized welded wire mesh panel, partnering with a reputable manufacturer is paramount. The quality, consistency, and reliability of the product directly reflect the manufacturer's expertise and commitment to standards. Here’s what to look for when comparing manufacturers:

- Certifications and Compliance: A leading manufacturer will hold certifications such as ISO 9001 (Quality Management System) and adhere strictly to international standards like ASTM A123/A123M (for galvanization), ASTM A185/A185M (for welded wire reinforcement), and relevant national standards. This ensures product consistency and reliability.

- Experience and Track Record: Look for manufacturers with a long history in the industry and a proven track record of successful projects and satisfied clients. Companies with over two decades of experience, for instance, often possess deeper expertise.

- Advanced Manufacturing Capabilities: Assess their production facilities for automation, precision welding equipment, and robust galvanization lines. This indicates their capacity to produce high-quality, uniform panels, including specialized items like 2x2 galvanized welded wire mesh panel or large 6x6 galvanized wire mesh.

- Quality Control Protocols: Inquire about their in-house testing and quality assurance procedures. A reputable manufacturer will have stringent checks at every stage, from raw material inspection to final product verification.

- Customization and Engineering Support: The ability to provide bespoke solutions (e.g., specific mesh sizes, wire gauges, or panel dimensions) and offer technical advice (e.g., on load-bearing capacities for 1 8 galvanized wire mesh) is a sign of a customer-centric approach.

- Customer Service and After-Sales Support: Responsiveness, clear communication, and comprehensive after-sales support (including warranty and technical assistance) are crucial for a smooth purchasing experience.

- Environmental Responsibility: Manufacturers committed to sustainable practices, such as waste reduction and energy efficiency, align with modern industry values.

By thoroughly vetting manufacturers based on these criteria, businesses and individuals can ensure they receive high-quality galvanized welded wire mesh panel products that meet their specific requirements and perform reliably over time.

Customization Solutions and Services

Recognizing that one size does not fit all, leading manufacturers offer extensive customization options for galvanized welded wire mesh panel. These tailored solutions ensure that clients receive products precisely suited to their unique project demands. Common customization aspects include:

- Dimensions: Panels can be produced in virtually any length and width to minimize waste and optimize installation. Whether you need an unusual height for a security fence or a specific length for a machinery guard, custom dimensions are available.

- Mesh Opening Sizes: Beyond standard sizes like 2x2 galvanized wire mesh, 4x4 galvanized wire mesh, and 6x6 galvanized wire mesh, manufacturers can produce panels with non-standard square or rectangular openings to meet specific filtration, security, or aesthetic requirements.

- Wire Gauges: The wire diameter can be precisely specified, from lighter gauges for decorative or light-duty applications to very heavy gauges for high-security barriers or structural reinforcement where 1 8 galvanized wire mesh might be considered a base.

- Edge Finishing: Options for panel edges, such as selvedge (finished edges for stability and safety) or raw cuts, can be specified depending on the application.

- Post-Galvanization Treatments: While hot-dip galvanization provides excellent protection, additional treatments like powder coating can be applied over the galvanized layer for specific aesthetic requirements (color matching) or enhanced protection in extremely corrosive environments.

- Fabrication Services: Many manufacturers offer in-house fabrication services, including cutting, bending, rolling, and even welding additional frames or supports, delivering ready-to-install components.

- Packaging: Custom packaging solutions, such as palletized bundles, crating, or shrink-wrapping, ensure safe transportation and easier handling on-site.

Engaging with a manufacturer's technical sales or engineering team early in the project planning phase can help optimize the design and ensure the most cost-effective and functional galvanized welded wire mesh panel solution is achieved.

Application Cases and Industry Applications

The versatility and durability of galvanized welded wire mesh panel make them indispensable across a wide array of industries and applications. Here are some prominent examples:

- Construction and Infrastructure:

- Concrete Reinforcement: Especially large mesh sizes like 6x6 galvanized wire mesh are extensively used as welded wire reinforcement (WWR) in concrete slabs, roadways, precast concrete products, and foundations to control cracking and improve structural integrity. Its galvanized coating protects against corrosion within the concrete matrix, ensuring long-term structural stability.

- Gabions: Galvanized welded wire mesh panel are assembled into rectangular or cylindrical baskets (gabions) and filled with rocks, used for retaining walls, erosion control along riverbanks, slope stabilization, and architectural features. The inherent strength and corrosion resistance of the mesh ensure the longevity of these structures in demanding environments.

- Partition Walls and Enclosures: Used in industrial warehouses, factories, and commercial buildings to create secure storage areas, machinery guards, or temporary partitions.

- Security and Fencing:

- Perimeter Fencing: Widely employed for high-security fencing around industrial sites, airports, military bases, and correctional facilities due to its robust nature and resistance to cutting and climbing.

- Animal Enclosures: Smaller mesh sizes like 2x2 galvanized welded wire mesh panel and 1 8 galvanized wire mesh are perfect for animal cages, kennels, and farm enclosures, providing secure containment while allowing visibility and airflow. Its non-toxic galvanized coating is safe for animals.

- Property Fencing: Durable and long-lasting fencing for residential and commercial properties, offering security without obstructing views.

- Agriculture and Horticulture:

- Livestock Panels: Used for creating corrals, pens, and feedlot barriers.

- Trellises and Plant Supports: In gardening and viticulture, they support climbing plants and vines.

- Pest Control: Fine mesh panels can act as barriers against rodents and other pests.

- Industrial and Manufacturing:

- Machine Guards: Protecting workers from moving parts while allowing visibility and ventilation.

- Storage Shelving: Strong and durable surfaces for industrial shelving units.

- Filtration: In some cases, fine mesh can be used for coarse filtration applications.

- Mining and Energy:

- Mine Support: Used as rockfall protection and ground support in mining operations.

- Security Cages: For securing valuable equipment or hazardous areas in energy facilities.

Client Feedback: A recent project involving a large-scale agricultural facility required over 10,000 square meters of 2x2 galvanized welded wire mesh panel for animal enclosures. The client reported significant savings in long-term maintenance costs due to the material's inherent corrosion resistance and robust construction, praising the ease of installation and the aesthetic appeal that blended well with their farm environment. "The durability is unmatched," commented the farm manager, "and the galvanized coating means we won't be dealing with rust for decades, which is a huge benefit for our operational budget." This practical experience highlights the product's real-world value.

Frequently Asked Questions (FAQ) about Galvanized Welded Wire Mesh Panel

To further enhance understanding and address common queries, here are answers to frequently asked questions regarding galvanized welded wire mesh panel:

- Q: What is the difference between hot-dip galvanized and electro-galvanized welded wire mesh panels?

A: Hot-dip galvanized after welding (HDGAW) panels are fully submerged in molten zinc after fabrication, resulting in a thick, uniform coating (typically 45-85 µm) that covers all welds, offering superior corrosion resistance and a longer lifespan. Electro-galvanized wire mesh uses wires that are galvanized before welding, resulting in a thinner, brighter coating (10-30 µm), but the weld points may have less protection. HDGAW is generally preferred for outdoor and demanding applications. - Q: How long does a galvanized welded wire mesh panel last?

A: The lifespan largely depends on the galvanization type and environmental conditions. Hot-dip galvanized panels can last 30 to 50 years or even more in typical atmospheric conditions. In highly corrosive environments (e.g., marine, industrial), the lifespan might be reduced but still significantly longer than non-galvanized alternatives. - Q: Can galvanized welded wire mesh panel be cut or bent?

A: Yes, these panels can be cut using bolt cutters or angle grinders and bent using appropriate tools, though bending thicker gauges or large panels may require specialized machinery. The galvanized coating around the cut or bent area might be minimally affected, but the sacrificial protection of the zinc layer helps protect exposed steel. - Q: Is 2x2 galvanized welded wire mesh panel suitable for animal cages?

A: Absolutely. A 2x2 galvanized welded wire mesh panel offers an ideal balance of security, visibility, and safety for various animals, from poultry to small livestock. The galvanized coating is non-toxic and provides excellent rust protection, ensuring a clean and safe environment for animals. - Q: What standards should I look for when purchasing galvanized welded wire mesh panel?

A: Key standards include ASTM A123/A123M for hot-dip galvanizing, ASTM A185/A185M for welded steel wire reinforcement, and ISO 1461 for hot-dip galvanized coatings on fabricated iron and steel articles. Compliance with ISO 9001 (Quality Management System) indicates a manufacturer's commitment to consistent quality. - Q: Can these panels be painted or coated?

A: While hot-dip galvanized panels offer sufficient protection and aesthetic appeal, they can be painted or powder-coated for specific color requirements or enhanced protection. Proper surface preparation (e.g., light abrasion, T-wash) is essential to ensure paint adhesion. - Q: What is 1 8 galvanized wire mesh commonly used for?

A: 1 8 galvanized wire mesh typically refers to a wire diameter of approximately 1/8 inch (or 3.175mm). This robust wire gauge, combined with various mesh openings, makes it suitable for heavy-duty applications such as machine guards, security enclosures, concrete reinforcement, and animal containment where significant strength and durability are required.

Delivery and Warranty Information

At HardwareInStore, we are committed to providing seamless service from order to delivery. Our typical delivery lead time for standard galvanized welded wire mesh panel orders ranges from 7 to 14 business days, depending on order volume and destination. For custom orders or large quantities (e.g., hundreds of 2x2 galvanized welded wire mesh panel for a commercial project), lead times may extend to 3-4 weeks. We offer various shipping options, including LTL (Less Than Truckload) and full truckload, to accommodate different order sizes and ensure timely and cost-effective delivery across regions.

We stand behind the quality of our galvanized welded wire mesh panel products. All panels come with a comprehensive warranty against manufacturing defects and premature corrosion under normal use conditions. Our hot-dip galvanized products are typically warranted for 10-20 years against red rust perforation, reflecting our confidence in their long-term performance and adherence to industry standards like ASTM A123/A123M. For detailed warranty terms and conditions, please refer to our official product documentation or contact our customer support team.

Conclusion: The Enduring Value of Galvanized Welded Wire Mesh Panels

The galvanized welded wire mesh panel is far more than a simple fencing material; it is a sophisticated engineered product that combines the strength of steel with the unparalleled corrosion resistance of zinc. From its meticulous manufacturing process, involving precision welding and thorough hot-dip galvanization, to its diverse applications in construction, agriculture, security, and industry, this material offers exceptional value. Its technical advantages—superior corrosion resistance, high strength-to-weight ratio, ease of installation, and minimal maintenance—translate into significant long-term cost savings and enhanced structural integrity. By understanding the critical technical parameters, choosing reputable manufacturers, and exploring customization options, clients can leverage the full potential of products like 2x2 galvanized welded wire mesh panel, 4x4 galvanized wire mesh, and 6x6 galvanized wire mesh for their specific needs. As industries continue to seek durable, sustainable, and reliable solutions, the galvanized welded wire mesh panel will undoubtedly remain a cornerstone, providing robust and lasting performance across countless applications.

For further academic and industry insights into the properties and applications of galvanized steel, readers may find valuable information from organizations such as the American Galvanizers Association (AGA) or research published in material science journals.

References and Further Reading:

- Grand View Research. (2023). Wire Mesh Market Size, Share & Trends Analysis Report. Retrieved from [https://www.grandviewresearch.com/industry-analysis/wire-mesh-market](https://www.grandviewresearch.com/industry-analysis/wire-mesh-market) (Note: Direct content access may require subscription or specific permissions for full report details.)

- American Society for Testing and Materials (ASTM International). Standards for Galvanized Coatings and Welded Wire Reinforcement. Retrieved from [https://www.astm.org/](https://www.astm.org/)

- International Organization for Standardization (ISO). ISO 1461: Hot-dip galvanized coatings on fabricated iron and steel articles. Retrieved from [https://www.iso.org/standard/27040.html](https://www.iso.org/standard/27040.html)

- American Galvanizers Association. (n.d.). Durability of Hot-Dip Galvanizing. Retrieved from [https://galvanizeit.org/hot-dip-galvanizing/what-is-hot-dip-galvanizing/durability](https://galvanizeit.org/hot-dip-galvanizing/what-is-hot-dip-galvanizing/durability)

-

Custom Weld Mesh – Tailored Solutions for Durable Industrial Fencing & Construction

NewsNov.24,2025

-

Comprehensive Guide to Chicken Welded Wire Mesh: Uses, Benefits & Suppliers

NewsNov.23,2025

-

BRC Weld Mesh – Durable Reinforcement Solutions for Modern Construction

NewsNov.23,2025

-

Durable BRC 3315 Mesh for Reliable Concrete Reinforcement | Hardware In Store

NewsNov.23,2025

-

Discover the Benefits of Green Weld Mesh – Durable, Sustainable Fencing Solutions

NewsNov.22,2025

-

Electro Welded Mesh: Durable, Versatile Steel Grid Solutions | HardwareInStore

NewsNov.22,2025

Products categories