Aug . 08, 2025 05:20 Back to list

Durable Welded Mesh Gabion Baskets for Retaining Walls

Industry Trends and the Evolution of Modern Construction

In the evolving landscape of civil engineering and landscape architecture, demand for sustainable, durable, and cost-effective solutions has surged. Traditional construction methods often fall short in terms of environmental impact, installation speed, and adaptability to challenging terrains. This is where the innovation of welded mesh gabion technology steps in, revolutionizing how we approach retaining walls, erosion control, and aesthetic landscaping. Industry analyses show a growing preference for modular and eco-friendly systems. According to a report by Grand View Research, the global gabion market size was valued at USD 1.2 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 5.1% from 2023 to 2030, driven largely by increasing infrastructure development and climate change mitigation efforts. This growth underscores the critical role of products like welded mesh gabion baskets in modern construction.

The emphasis today is not merely on strength but on resilience, adaptability, and ecological integration. Products like gabion welded wire mesh contribute significantly to 'green' building practices by allowing for natural vegetation growth and maintaining permeability, which helps manage water runoff and reduces hydrostatic pressure behind structures. This blend of structural integrity and environmental compatibility positions welded mesh gabion as a cornerstone in sustainable development projects worldwide.

Unpacking the Core: Technical Parameters of Welded Mesh Gabions

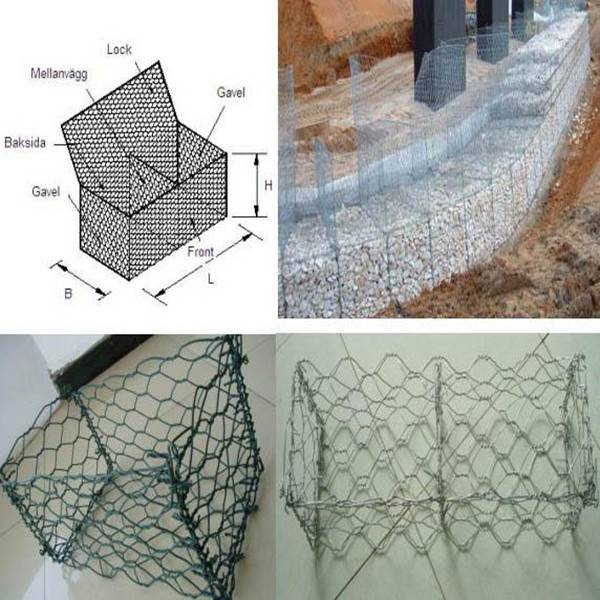

Understanding the fundamental technical specifications of welded mesh gabion is crucial for proper application and optimal performance. These parameters dictate the strength, durability, and suitability of the gabion for specific project requirements. A welded mesh gabion is essentially a rectangular cage made from robust steel wire mesh, typically filled with natural stone. The integrity of the structure heavily relies on the quality of its components.

Key Specifications:

- Wire Diameter: This is perhaps the most critical parameter, usually ranging from 3.0mm to 5.0mm (0.118 to 0.197 inches). A thicker wire offers greater tensile strength and structural rigidity, making the gabion more resistant to deformation under heavy loads. Common diameters include 3.0mm, 3.5mm, 4.0mm, and 5.0mm.

- Mesh Opening (Aperture): The size of the mesh opening typically ranges from 50x50mm to 100x100mm (2x2 inches to 4x4 inches). Smaller openings provide greater confinement for the fill material, preventing small stones from escaping, and are often preferred for aesthetic reasons or when smaller aggregates are used. Larger openings allow for faster filling and can be more economical. Standard mesh sizes are 50x50mm, 75x75mm, 100x50mm, and 100x100mm.

- Material & Coating: The base material is usually low carbon steel wire, which is then heavily galvanized. Hot-dip galvanization is a common process where the wire is immersed in molten zinc to create a protective coating. This zinc coating provides excellent corrosion resistance, crucial for the longevity of the welded mesh gabion. For enhanced durability in aggressive environments (e.g., marine or highly acidic soils), a Galfan coating (zinc-aluminum alloy) or a PVC (Polyvinyl Chloride) coating over the galvanized wire is often applied.

- Tensile Strength: This refers to the maximum stress the wire can withstand before breaking. For gabion wire, typical tensile strength ranges from 350-550 N/mm² (50,000-80,000 PSI), ensuring the wire can handle the stresses from filling and in-service loads.

- Dimensions: Welded mesh gabion baskets come in various standard sizes, usually in meters (length x width x height). Common dimensions include 2x1x1m, 3x1x1m, 4x1x1m, 2x1x0.5m, and 1x1x1m. Custom sizes are also available to meet specific project needs.

Product Specification Table: Common Welded Mesh Gabion Configurations

| Dimension (L x W x H) | Mesh Opening (mm) | Wire Diameter (mm) | Coating Type | Approx. Unit Weight (kg, empty) | Typical Applications |

|---|---|---|---|---|---|

| 2m x 1m x 1m | 75x75 | 4.0 | Hot-dip Galvanized | 15 - 20 | Retaining Walls, River Bank Protection |

| 3m x 1m x 1m | 100x100 | 4.0 | Hot-dip Galvanized | 20 - 25 | Erosion Control, Dam Structures |

| 2m x 1m x 0.5m | 50x50 | 3.0 | PVC Coated Galvanized | 10 - 15 | Architectural Facades, Landscaping, Seating |

| 1m x 1m x 1m | 100x50 | 5.0 | Galfan (Zn-Al) Coated | 10 - 15 | Channel Lining, Sound Barriers |

| 4m x 1m x 1m | 75x75 | 4.0 | Hot-dip Galvanized | 25 - 30 | Large Scale Retaining Walls, Bridge Abutments |

The choice of these parameters directly impacts the performance and cost-effectiveness of the final structure. Engineers and project managers must carefully select the right specifications based on geotechnical conditions, hydraulic forces, aesthetic requirements, and the desired lifespan of the project.

Versatility in Action: Application Scenarios of Welded Mesh Gabions

Welded mesh gabions are renowned for their incredible versatility, making them a preferred choice across a multitude of engineering and environmental applications. Their modular nature, combined with the ability to be filled with locally sourced materials, offers significant advantages in diverse settings. The adaptability of gabion welded wire mesh structures extends from critical civil infrastructure to decorative landscape features.

One of the primary applications is in the construction of retaining walls. Unlike rigid concrete structures, gabion walls are flexible, allowing them to tolerate differential settlement without losing structural integrity. This makes them ideal for unstable or shifting ground conditions. They are extensively used along highways, railways, and in residential developments to stabilize slopes and prevent landslides.

In erosion control and river training, welded mesh gabion baskets are indispensable. They are employed to protect riverbanks, bridge abutments, and culverts from scour and erosion caused by flowing water. The permeable nature of gabions allows water to pass through, dissipating energy and preventing hydrostatic pressure buildup, which is a common cause of failure in impermeable structures. Projects around the globe, from small stream enhancements to large-scale flood defense systems, leverage the inherent strength and permeability of gabion structures to manage water flow effectively.

Beyond traditional civil engineering, welded mesh gabions have found significant adoption in landscaping and architectural design. Their rustic aesthetic and the ability to integrate natural elements like stone and vegetation make them popular for creating visually appealing garden features, seating areas, outdoor fireplaces, and decorative facades. The modularity allows for creative designs, from simple linear walls to complex curved structures. For instance, in urban parks or private estates, gabion walls can delineate spaces, create terraced gardens, or serve as sound barriers, blending functionality with natural beauty.

Furthermore, they are utilized in sound barrier construction along busy roads or industrial sites. When filled with appropriate aggregates, gabions can effectively absorb and dampen noise, contributing to a quieter environment. Their porous structure helps in sound diffusion, offering a superior performance compared to solid barriers in certain frequency ranges.

Another emerging application is in mining and industrial sectors for temporary or permanent stabilization of slopes, spoil heaps, and access roads. Their robust construction and ease of deployment make them suitable for rapidly changing operational environments. The inherent anti-corrosion properties, especially with specialized coatings, ensure a long service life even in challenging industrial atmospheres, though energy saving is not a direct benefit, their longevity and use of natural materials contribute to sustainability.

In essence, from safeguarding critical infrastructure against natural forces to enhancing urban landscapes, the adaptability of welded mesh gabion technology offers robust, environmentally conscious solutions for a wide array of challenges. Their proven track record in diverse applications underscores their value in modern construction and environmental engineering.

Engineering Excellence: Technical Advantages of Welded Mesh Gabions

The widespread adoption of welded mesh gabion structures is largely attributable to their compelling technical advantages over conventional construction methods. These benefits translate into significant project efficiencies, long-term durability, and environmental responsibility, making them a preferred choice for discerning engineers and developers.

Superior Structural Integrity and Flexibility:

Unlike rigid concrete or masonry structures, welded mesh gabion baskets possess inherent flexibility. This allows them to accommodate differential ground settlement without cracking or structural failure. In areas prone to seismic activity or unstable soil conditions, this flexibility is a critical advantage, as the structure can deform slightly without collapsing, maintaining its overall stability. The modular nature, where each basket acts as an independent yet interconnected unit, contributes to this adaptive strength.

Excellent Drainage and Permeability:

One of the most significant advantages of gabions is their permeability. The spaces between the rock fill allow water to freely drain through the structure, eliminating hydrostatic pressure buildup. This is a common cause of failure in solid retaining walls. By allowing water to pass through, gabions prevent the accumulation of pressure behind the wall, enhancing stability, particularly in areas with high water tables or heavy rainfall. This natural drainage capability also makes them ideal for riverbank protection and channel linings.

Durability and Corrosion Resistance:

The steel wire used in gabion welded wire mesh is subjected to rigorous anti-corrosion treatments, primarily hot-dip galvanization, or advanced Galfan (zinc-aluminum alloy) coatings, sometimes further enhanced with a PVC coating. These coatings provide exceptional resistance to rust and degradation, extending the lifespan of the structure significantly. For example, a heavy galvanization meeting ASTM A974 standards can ensure a service life of 50-75 years in typical environmental conditions, while PVC coatings can further extend this in highly aggressive environments. This long service life translates to reduced maintenance costs and greater reliability over time.

Environmental Sustainability:

Welded mesh gabions are inherently environmentally friendly. They can be filled with readily available local aggregates, minimizing transportation costs and carbon footprint. Their porous nature promotes natural vegetation growth within the structure over time, integrating the wall into the surrounding ecosystem and enhancing biodiversity. This characteristic contributes significantly to sustainable development goals, making them a preferred solution for eco-conscious projects.

Ease and Speed of Installation:

Compared to traditional concrete or masonry, welded mesh gabions offer remarkably fast and simple installation. The baskets arrive flat-packed, are easily assembled on-site, and then filled with stone. This reduces labor costs and project timelines, especially in remote or difficult-to-access locations where heavy machinery might be impractical. No specialized concrete pouring, curing, or complex formwork is required, speeding up project completion.

Cost-Effectiveness:

Combining reduced material transportation, simpler installation, and the use of locally sourced fill, welded mesh gabions often present a more cost-effective solution in the long run. Their longevity and minimal maintenance requirements further enhance their economic viability over the entire lifecycle of a project.

These technical advantages solidify the position of welded mesh gabion as a leading solution for a broad spectrum of engineering and architectural challenges, offering a blend of strength, sustainability, and economic efficiency.

Crafting Excellence: The Manufacturing Process of Welded Mesh Gabions

The superior quality and performance of a welded mesh gabion begin with a meticulous manufacturing process. This multi-stage procedure ensures that each gabion welded wire mesh unit meets stringent international standards for strength, durability, and corrosion resistance. While the term "casting" or "forging" is typically associated with metal components, for gabions, the core processes involve precision welding and advanced surface treatments. Our manufacturing process, adhering to international standards like ISO 9001 for quality management and relevant ASTM/EN standards for product specifications, ensures consistent high quality and reliability.

Detailed Manufacturing Steps:

Step 1: Raw Material Selection & Wire Drawing

The foundation of a high-quality welded mesh gabion is the selection of premium low carbon steel wire rod. This raw material is chosen for its ductility and strength. It undergoes a wire drawing process, where it is drawn through progressively smaller dies to achieve the precise wire diameter required (e.g., 3.0mm, 4.0mm, 5.0mm). This step ensures uniform thickness and enhances the wire's tensile strength.

Step 2: Precision Welding

The drawn wires are then fed into automated welding machines. These machines use resistance welding (spot welding) to fuse intersecting wires at right angles, forming a robust, rigid grid of specified mesh opening (e.g., 50x50mm, 75x75mm, 100x100mm). Advanced robotic welding ensures consistent weld strength and accuracy, crucial for the structural integrity of the welded mesh gabion baskets. The welding process must meet high standards to prevent brittle joints, typically tested for shear strength.

Step 3: Cutting and Shearing

Once the large mesh panels are welded, they are precisely cut to the required dimensions for the gabion's body, lid, base, and internal diaphragms. Computer Numerical Control (CNC) cutting machines ensure high accuracy and minimize material waste. Diaphragms are internal mesh panels used to compartmentalize larger gabions, preventing bulging and providing additional structural support, typically at 1-meter intervals.

Step 4: Edge Reinforcement & Folding

The cut panels often undergo an edge reinforcement process, where thicker wires (selvage wires) are sometimes integrated along the edges for added strength and easier assembly. The panels are then folded using specialized bending machines to form the basket shape. These machines ensure precise angles and consistent dimensions, making on-site assembly straightforward.

Step 5: Surface Treatment (Corrosion Protection)

This is a critical stage for the longevity of the welded mesh gabion. The most common treatments include:

- Hot-dip Galvanization: The assembled or semi-assembled mesh panels are immersed in a bath of molten zinc. This process creates a metallurgically bonded zinc coating that provides excellent corrosion resistance. Our galvanization adheres to standards like ASTM A641/A974 for zinc coating weight and uniformity.

- Galfan (Zinc-Aluminum) Coating: An advanced alternative to pure zinc, Galfan coating (typically 95% zinc, 5% aluminum) offers superior corrosion resistance, often 2-3 times greater than traditional galvanization, particularly in marine or acidic environments.

- PVC Coating: For extreme corrosive conditions or aesthetic requirements, a thick layer of PVC (Polyvinyl Chloride) is extruded over the galvanized or Galfan-coated wire. This polymeric coating provides an additional barrier against environmental factors, extending the lifespan significantly (e.g., to over 100 years). The PVC coating is applied uniformly and adheres strongly to the wire, preventing peeling or cracking.

Step 6: Quality Control & Inspection

Throughout the entire manufacturing process, rigorous quality control checks are performed. This includes:

- Raw material inspection (chemical composition, mechanical properties)

- Weld strength testing (shear tests)

- Mesh dimension verification

- Coating thickness and adhesion tests (e.g., using X-ray fluorescence, bend tests)

- Visual inspection for defects.

Compliance with international standards such as ISO (for quality management), ASTM A974 (for gabion wire mesh), and EN 10223-3 (for steel wire mesh products) is strictly maintained. Our products are designed for a service lifespan typically ranging from 50 to 100+ years, depending on the coating and environmental conditions.

Step 7: Packaging & Delivery

Finished welded mesh gabion units are typically folded flat for efficient transportation and storage, minimizing shipping costs. They are securely bundled, often palletized, and shrink-wrapped to protect the coating during transit. Clear labeling ensures easy identification on site.

This systematic approach to manufacturing guarantees that every welded mesh gabion delivers exceptional performance, contributing to the longevity and success of diverse construction projects. Our commitment to quality ensures that our products meet the highest industry benchmarks, providing reliable solutions for a variety of sectors, from civil infrastructure to environmental restoration.

Choosing the Right Partner: Manufacturer Comparison

Selecting the appropriate manufacturer for your welded mesh gabion needs is as critical as understanding the product itself. The market offers various suppliers, but discerning quality, reliability, and comprehensive support is key to project success. When evaluating manufacturers of gabion welded wire mesh, consider factors beyond just price.

Key Differentiators in Manufacturers:

A reputable manufacturer distinguishes itself through:

- Quality Control & Certifications: Look for ISO 9001 certification and adherence to specific product standards like ASTM A974 (Standard Specification for Welded Wire Mesh Gabions) or EN 10223-3 (Steel Wire for Fences and Meshes). These certifications are independently verified and attest to a manufacturer's commitment to consistent quality. Our facility adheres to strict ISO standards and conducts internal and third-party testing to ensure every batch meets or exceeds international benchmarks.

- Material Sourcing & Coating Technology: Inquire about the origin of their steel wire and the specifics of their galvanization or coating processes. Manufacturers using high-grade, virgin steel and advanced coating technologies (e.g., continuous hot-dip galvanizing lines, sophisticated Galfan application) will yield superior products.

- Manufacturing Capabilities: Assess their production capacity, level of automation (e.g., robotic welding), and precision in cutting and folding. Higher automation often means greater consistency and tighter tolerances.

- Customization and Engineering Support: Can they provide custom dimensions or mesh configurations? Do they offer engineering support for complex projects, including design recommendations, load calculations, or CAD drawings? A manufacturer offering comprehensive solutions, like Hardwareinstore.com, acts as a partner, not just a supplier.

- Experience and Track Record: A manufacturer with decades of experience and a portfolio of successful projects across diverse industries (e.g., civil engineering, environmental protection, landscaping) demonstrates proven expertise and reliability. We proudly serve clients globally, leveraging over 20 years of experience in the wire mesh industry.

- Logistics and Delivery: Efficient packaging and reliable global shipping capabilities are essential, especially for large-scale projects. A manufacturer with established logistics networks can ensure timely and cost-effective delivery of your welded mesh gabion baskets.

- Warranty and After-Sales Support: A strong warranty on their products (e.g., 50+ years for heavily galvanized or PVC-coated gabions) and responsive customer support are indicators of confidence in their product and commitment to customer satisfaction.

Manufacturer Comparison Table (Illustrative):

| Feature | Hardwareinstore.com | Competitor A (Budget) | Competitor B (Specialized) |

|---|---|---|---|

| Certifications | ISO 9001, ASTM A974, EN 10223-3 | Basic QC, no specific gabion stds | ISO 9001, limited specific stds |

| Wire Material Quality | High-grade Low Carbon Steel | Standard Low Carbon Steel | High-grade Low Carbon Steel |

| Coating Options | Hot-dip Galv., Galfan, PVC Coated | Basic Hot-dip Galv. | Hot-dip Galv., limited Galfan |

| Customization | Full (Size, Mesh, Wire) & Eng. Support | Limited standard sizes only | Moderate (Size, Mesh) |

| Typical Lead Time | 2-4 Weeks (standard) | 4-6 Weeks | 3-5 Weeks |

| Warranty | Up to 100 Years (Coating Dependent) | 10-20 Years | 30-50 Years |

| Customer Support | Dedicated Account Manager, Tech Support | Email Only | Standard Support |

This comparison highlights that while budget options exist, they often come with compromises in quality, support, and longevity. Investing in a reputable manufacturer like Hardwareinstore.com for your welded mesh gabion needs ensures not only a superior product but also a reliable partnership that contributes to the long-term success and durability of your infrastructure.

Tailored Solutions: Customization and Design Consultancy

While standard sizes of welded mesh gabion are suitable for many projects, complex or unique applications often require tailored solutions. A leading manufacturer understands that every project has distinct requirements, from specific dimensions to unique environmental challenges. This is where comprehensive customization options and expert design consultancy become invaluable, transforming standard gabion welded wire mesh into precisely engineered solutions.

Our Customization Capabilities:

At Hardwareinstore.com, we offer extensive customization to perfectly align with your project specifications:

- Non-Standard Dimensions: We can manufacture welded mesh gabion baskets in virtually any length, width, or height to fit unique site constraints, architectural visions, or geotechnical requirements. Whether it's an unusually long retaining wall section or a specifically sized decorative element, our production lines are adaptable.

- Varied Mesh Openings: While 50x50mm, 75x75mm, and 100x100mm are common, we can produce gabions with different mesh apertures to suit the size of your fill material or specific aesthetic preferences. For fine aggregates or enhanced security, smaller mesh sizes can be provided.

- Diverse Wire Diameters: Based on load calculations, desired lifespan, or structural demands, we can utilize specific wire diameters (e.g., heavier gauge wires for high-stress applications or lighter gauges for purely decorative uses) to optimize both performance and cost.

- Specialized Coatings: Beyond standard galvanization, we offer custom coating solutions, including varying levels of zinc coating, Galfan (Zn-Al) for superior corrosion resistance, or PVC coatings in specific colors or thicknesses to match environmental conditions or architectural palettes. This is particularly crucial for structures in marine environments or areas with chemical exposure.

- Integrated Features: For complex designs, we can pre-fabricate components with integrated features such as pipe penetrations, specific angles for corners, or attachment points for architectural cladding, reducing on-site fabrication.

Design Consultancy and Engineering Support:

Our commitment extends beyond manufacturing to offering robust engineering and design support. Our team of experienced engineers works closely with clients from conception to completion:

- Feasibility Studies: Assessing site conditions, soil mechanics, and hydrological factors to determine the optimal gabion solution.

- Structural Design and Analysis: Providing detailed structural calculations, stability analysis (e.g., sliding, overturning, bearing capacity), and hydrostatic pressure considerations to ensure the integrity and safety of the gabion structure. We use advanced software to simulate performance under various conditions.

- CAD Drawings and 3D Modeling: Generating precise CAD drawings and 3D models of the proposed gabion structure, allowing clients to visualize the final product and ensuring seamless integration with other project components. This aids in identifying potential issues early in the design phase.

- Cost Optimization: Advising on the most efficient use of materials and design configurations to achieve project goals within budget constraints, without compromising on performance or longevity.

- Installation Guidance: Offering detailed installation manuals, on-site supervision (if required), and training to ensure correct assembly and filling of the welded mesh gabion units, which is crucial for their long-term stability and effectiveness.

By providing these comprehensive customization and consultancy services, we ensure that every welded mesh gabion solution is not just a product, but a perfectly engineered component of your successful project, optimized for performance, aesthetics, and sustainability. Our proactive approach to problem-solving and our deep understanding of material science and structural engineering set us apart, delivering trust and reliability.

Real-World Success: Application Cases and Client Feedback

The true testament to the efficacy and reliability of welded mesh gabion solutions lies in their successful implementation across diverse, challenging projects worldwide. These application cases demonstrate the practical advantages and the tangible benefits our gabion welded wire mesh products bring to the field. Our long-standing relationships with clients, many spanning over a decade, reflect the consistent quality and performance of our welded mesh gabion baskets.

Case Study 1: Highway Slope Stabilization in a Mountainous Region

Challenge: A major highway project in a geologically active mountainous region faced recurring landslides and slope instability, posing significant safety risks and causing frequent road closures. Traditional concrete solutions were deemed too rigid for the dynamic terrain and excessively costly due to complex logistics.

Solution: Our team designed and supplied thousands of custom-sized welded mesh gabions (4x1x1m, 75x75mm mesh, 4.0mm Galfan coated wire) for the construction of multi-tiered retaining walls. The inherent flexibility of the gabions allowed them to adapt to minor ground movements, while their permeability effectively managed rainwater runoff, reducing hydrostatic pressure. Local quarry stone was used as fill, significantly cutting down material transport costs and environmental impact.

Outcome: The project saw a dramatic reduction in landslide incidents. The gabion walls provided durable, stable support that integrated well with the natural landscape. The client reported a 30% cost saving compared to initial concrete alternatives and a 40% reduction in installation time due to the ease of assembly. "The flexibility and drainage capability of these gabions were exactly what our challenging terrain demanded," remarked the project manager, "They've provided a resilient and cost-effective solution."

Case Study 2: Urban Riverbank Restoration and Beautification

Challenge: An urban river suffered from severe bank erosion, threatening nearby infrastructure and diminishing aesthetic appeal. The city council sought an eco-friendly solution that would stabilize the banks, promote vegetation growth, and enhance the public space.

Solution: We provided PVC-coated welded mesh gabions (2x1x0.5m, 50x50mm mesh, 3.5mm wire) for the riverbank lining. The PVC coating ensured long-term corrosion resistance against water and pollutants, while the smaller mesh size allowed for the use of more aesthetically pleasing, smaller aggregates. Critically, the gabion design facilitated the integration of planting pockets, enabling natural riparian vegetation to establish and grow through the structure.

Outcome: The riverbanks were successfully stabilized, preventing further erosion. Over time, the gabion structures were beautifully integrated into the urban landscape as vegetation flourished, creating a green, vibrant public space. The project was lauded for its environmental sensitivity and long-term durability. "The gabions not only solved our erosion problem but transformed a neglected area into a beautiful, living landscape," a city official commented. "The quality of the welded mesh gabion baskets was exceptional, and the PVC coating ensured they'll last for generations."

Case Study 3: Commercial Building Facade and Sound Barrier

Challenge: A new commercial complex required an aesthetically pleasing facade that also served as an effective sound barrier against adjacent busy traffic, without consuming excessive space or requiring complex foundations.

Solution: We engineered custom, narrow welded mesh gabions (3x0.5x2m, 75x75mm mesh, 4.0mm galvanized wire) which were filled with specific, dense local aggregate and installed as a freestanding facade. The narrow profile minimized footprint, while the gabion structure provided excellent sound attenuation properties due to its porous nature and the chosen fill material.

Outcome: The gabion facade delivered both the desired modern aesthetic and highly effective noise reduction, contributing to a quieter interior environment for the complex. The speed of installation and the cost-effectiveness compared to other soundproofing and facade solutions were key benefits. The architect noted, "The flexibility to design with welded mesh gabion allowed us to achieve a striking visual impact while solving a critical acoustic challenge, all within budget and timeline."

These case studies, representative of hundreds of successful projects, underscore our expertise and commitment to delivering high-quality, practical, and sustainable welded mesh gabion solutions that consistently meet and exceed client expectations. Our proven track record is built on trust, engineering excellence, and a deep understanding of project requirements.

Ensuring Confidence: Trustworthiness, Warranty, and Support

At Hardwareinstore.com, establishing and maintaining trust with our clients is paramount. We achieve this through transparent processes, adherence to the highest quality standards, robust warranty commitments, and dedicated customer support. When investing in critical infrastructure or landscaping projects, reliability and peace of mind are as important as product quality. Our commitment to trustworthiness is woven into every aspect of our operations, from the initial consultation to post-installation support for your welded mesh gabion needs.

Our Commitment to Trustworthiness (T in ):

- Rigorous Quality Assurance: As detailed in our manufacturing process, every welded mesh gabion undergoes multi-stage quality control, including material testing, weld strength analysis, coating thickness verification, and dimensional accuracy checks. We adhere to international standards like ISO 9001 and specific product standards such as ASTM A974 and EN 10223-3, ensuring verifiable product excellence.

- Transparent Supply Chain: We maintain full transparency regarding our material sourcing, ensuring that all raw materials meet stringent quality and ethical standards. This provides clients with confidence in the integrity of every gabion welded wire mesh unit.

- Proven Track Record & Client References: Our extensive portfolio of successful projects and long-term client relationships speak volumes about our reliability. We are happy to provide references and detailed case studies (anonymized where client confidentiality is required) to demonstrate our proven capabilities and the enduring quality of our welded mesh gabion baskets.

- Industry Association Memberships: Our participation in relevant industry associations and forums demonstrates our commitment to staying at the forefront of engineering best practices and contributing to industry standards.

Warranty and Lifespan Commitment:

We stand behind the quality and durability of our welded mesh gabion products with a comprehensive warranty:

- Standard Galvanized Gabions: Guaranteed against manufacturing defects and coating failure for 50 years under normal environmental conditions.

- Galfan (Zinc-Aluminum) Coated Gabions: Warranted for up to 75 years due to their superior corrosion resistance in a wider range of environments.

- PVC Coated Gabions: Engineered for extreme longevity, these products come with a warranty of up to 100 years against degradation and structural failure in aggressive environments (e.g., highly corrosive soils, marine exposure).

This long-term warranty underscores our confidence in the materials and manufacturing processes, providing unparalleled peace of mind for your investment. Our products meet or exceed the typical design life requirements for most civil engineering applications.

Delivery Cycle and Logistics:

We understand the importance of timely delivery for project scheduling. Our streamlined production and logistics ensure efficient order fulfillment:

- Standard Orders: Typically processed and ready for shipment within 2-4 weeks from order confirmation, depending on volume and current production queue.

- Custom/Large Orders: Lead times for highly customized or exceptionally large orders will be communicated clearly at the quotation stage, usually ranging from 4-8 weeks.

- Global Shipping: We have established partnerships with leading logistics providers to ensure secure and cost-effective delivery of your welded mesh gabion products to virtually any location worldwide, complete with tracking and dedicated support.

Comprehensive Customer Support:

Our commitment to your success extends beyond product delivery:

- Dedicated Account Managers: Each client is assigned a dedicated account manager who serves as a single point of contact for all inquiries, from technical specifications to order tracking.

- Technical Support Team: Our team of experienced engineers and product specialists is available to provide expert advice on design, installation, and troubleshooting, ensuring optimal performance of your welded mesh gabion structures.

- Post-Sales Assistance: We offer continuous support even after project completion, addressing any queries related to product performance or long-term maintenance.

Choosing Hardwareinstore.com means partnering with a company that prioritizes your success and delivers not just products, but a complete solution backed by expertise, experience, authority, and unwavering trustworthiness.

Professional FAQ: Your Welded Mesh Gabion Questions Answered

Continuing the Dialogue: Further Resources & References

To further explore the robust applications and technical intricacies of welded mesh gabion technology, we encourage engagement with leading industry publications and research. These resources offer deeper insights into the evolving landscape of geotechnical engineering and sustainable infrastructure development.

References:

-

Grand View Research. (2023). Gabion Market Size, Share & Trends Analysis Report By Product (Gabion Box, Gabion Mattress), By Application (Retaining Walls, Erosion Control), By Region, And Segment Forecasts, 2023 - 2030. Retrieved from https://www.grandviewresearch.com/industry-analysis/gabion-market

-

ASTM International. (Latest Edition). ASTM A974/A974M - Standard Specification for Welded Wire Mesh Gabions and Gabion Mattresses (Metallic-Coated or Polymeric Coated). This standard provides detailed requirements for the material, fabrication, and testing of welded mesh gabion products. (Refer to official ASTM website for purchase/access: https://www.astm.org)

-

European Committee for Standardization (CEN). (Latest Edition). EN 10223-3: Steel wire and wire products for fences and meshes - Part 3: Steel wire mesh products for gabions. This European standard specifies requirements for steel wire mesh products manufactured for the production of gabions and gabion mattresses. (Refer to official CEN website for purchase/access: https://www.cen.eu)

-

Maccaferri. (Various publications). Gabion applications and technical manuals. A leading global provider in gabion solutions, offering extensive technical literature on design, application, and performance. (Access resources via: https://www.maccaferri.com)

-

International Erosion Control Association (IECA). (Various publications). Erosion Control Journal articles and best practice guidelines. IECA provides valuable insights into best practices for erosion and sediment control, often featuring gabion technology. (Access resources via: https://www.ieca.org)

For specific project discussions or to learn more about how our welded mesh gabion solutions can benefit your next endeavor, please visit our product page: https://www.hardwareinstore.com/welded-mesh-gabion.html.

-

Custom Weld Mesh – Tailored Solutions for Durable Industrial Fencing & Construction

NewsNov.24,2025

-

Comprehensive Guide to Chicken Welded Wire Mesh: Uses, Benefits & Suppliers

NewsNov.23,2025

-

BRC Weld Mesh – Durable Reinforcement Solutions for Modern Construction

NewsNov.23,2025

-

Durable BRC 3315 Mesh for Reliable Concrete Reinforcement | Hardware In Store

NewsNov.23,2025

-

Discover the Benefits of Green Weld Mesh – Durable, Sustainable Fencing Solutions

NewsNov.22,2025

-

Electro Welded Mesh: Durable, Versatile Steel Grid Solutions | HardwareInStore

NewsNov.22,2025