Jan . 17, 2025 02:48 Back to list

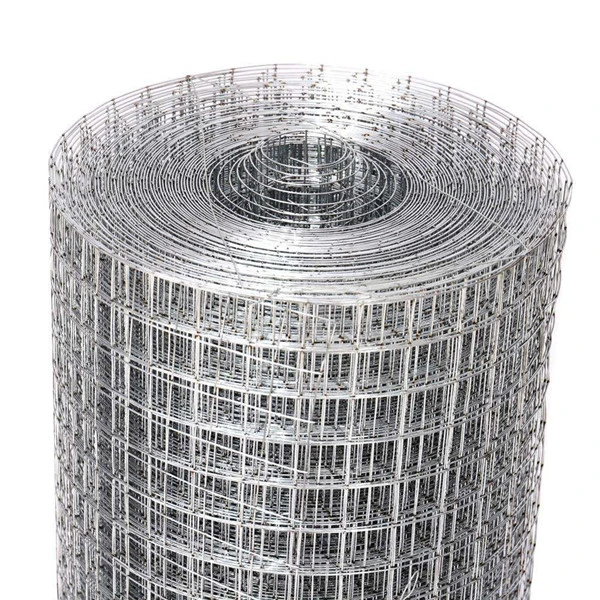

galvanized chicken wire mesh

Galvanised chicken wire mesh, a quintessential tool for both agricultural and architectural applications, stands as an indispensable resource in modern utility and design. Derived from a meticulous galvanization process, this mesh is coated with a layer of zinc to enhance its durability, making it resistant to rust and corrosion. The ensuing product is not only robust but also surprisingly versatile, serving as a pivotal component in various industries.

Safety and security are other indispensable aspects of galvanised chicken wire mesh. In urban settings, it is often employed as fencing to delineate property lines or to create security barriers around construction sites, preventing unauthorized access. It’s also used in building facades, placing an extra layer of safety to prevent debris from causing injury during refurbishments or demolitions. The expertise of manufacturers specializing in galvanised chicken wire mesh ensures that each product meets stringent quality standards. The galvanisation process itself signifies a commitment to longevity and safety, where each wire is uniformly coated to prevent environmental degradation. The precision in the weaving process ensures uniformity in mesh size, providing consistent quality across applications. Consumers trust brands that back their products with certifications and warranties, reinforcing the reliability and effectiveness of the wire mesh. When considering the authenticity of galvanised chicken wire mesh, it is critical to rely on authoritative sources. Reputable manufacturers often provide detailed specifications and usage guides, endorsing their products with empirical data from rigorous testing. This transparency builds trust with consumers, encouraging them to make informed purchasing decisions based not only on immediate needs but also on long-term value. In conclusion, galvanised chicken wire mesh embodies a blend of adaptability and resilience, making it a favored choice for varied applications ranging from farming and gardening to modern design and construction. Its multifaceted utility, underpinned by expert manufacturing practices, ensures it remains a go-to material for those seeking both functionality and innovation. Engaging with trusted manufacturers who uphold high standards of expertise and accountability enhances the product's appeal, ensuring it meets and exceeds user expectations in every use case.

Safety and security are other indispensable aspects of galvanised chicken wire mesh. In urban settings, it is often employed as fencing to delineate property lines or to create security barriers around construction sites, preventing unauthorized access. It’s also used in building facades, placing an extra layer of safety to prevent debris from causing injury during refurbishments or demolitions. The expertise of manufacturers specializing in galvanised chicken wire mesh ensures that each product meets stringent quality standards. The galvanisation process itself signifies a commitment to longevity and safety, where each wire is uniformly coated to prevent environmental degradation. The precision in the weaving process ensures uniformity in mesh size, providing consistent quality across applications. Consumers trust brands that back their products with certifications and warranties, reinforcing the reliability and effectiveness of the wire mesh. When considering the authenticity of galvanised chicken wire mesh, it is critical to rely on authoritative sources. Reputable manufacturers often provide detailed specifications and usage guides, endorsing their products with empirical data from rigorous testing. This transparency builds trust with consumers, encouraging them to make informed purchasing decisions based not only on immediate needs but also on long-term value. In conclusion, galvanised chicken wire mesh embodies a blend of adaptability and resilience, making it a favored choice for varied applications ranging from farming and gardening to modern design and construction. Its multifaceted utility, underpinned by expert manufacturing practices, ensures it remains a go-to material for those seeking both functionality and innovation. Engaging with trusted manufacturers who uphold high standards of expertise and accountability enhances the product's appeal, ensuring it meets and exceeds user expectations in every use case.

Pervious:

Next:

Latest news

-

Why a Chain Link Fence is the Right Choice

NewsJul.09,2025

-

Upgrade Your Fencing with High-Quality Coated Chicken Wire

NewsJul.09,2025

-

The Power of Fence Post Spikes

NewsJul.09,2025

-

The Best Pet Enclosures for Every Need

NewsJul.09,2025

-

Secure Your Property with Premium Barbed Wire Solutions

NewsJul.09,2025

-

Enhance Your Construction Projects with Quality Gabion Boxes

NewsJul.09,2025

Products categories

NEED HELP?

Don' t Hesitate To Contact Us For More Information About Company Or Service

CONTACT US