Nov . 19, 2024 14:49 Back to list

gabion wire specification

Understanding Gabion Wire Specifications

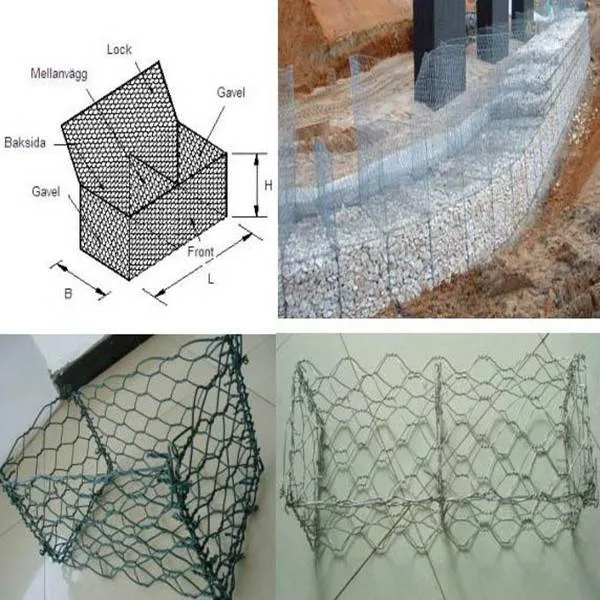

Gabions have become increasingly popular in construction and landscaping due to their durability, versatility, and environmental benefits. One critical component of gabions is the wire used to fabricate the mesh that forms their structure. Understanding gabion wire specifications is essential for ensuring that the right materials are selected for specific applications, ensuring structural integrity, and achieving desired aesthetic results.

Composition and Coating

Gabion wire is typically made from high-tensile steel, which offers excellent strength and flexibility. The specifications may include various grades of steel, including mild steel and galvanized steel. Galvanization involves coating the wire with a layer of zinc to enhance corrosion resistance. This coating is vital for gabions exposed to moisture, soil, and environmental conditions, as it prolongs the lifespan of the wire mesh. Standards such as ASTM A392 or EN 10223-4 often dictate the minimum requirements for galvanized wire, ensuring that it can withstand the elements.

The wire can also be coated with PVC for additional protection against corrosion and to enhance aesthetics. The type of coating—zinc, PVC, or a combination—will affect the gabion’s durability, and it’s important to select the right one based on the project’s environmental exposure.

Wire Diameter and Mesh Size

The diameter of the wire used in gabion construction is a critical specification. Common diameters range from 2.0 mm to 5.0 mm. Thicker wire increases the strength and stability of the gabion structure, making it suitable for more demanding applications such as retaining walls, riverbank stabilization, and erosion control. The choice of wire diameter should consider factors such as the anticipated load, environmental conditions, and the size of the rocks or materials contained within the gabion.

Mesh size is another important specification, as it dictates the size of the stones that can be used inside the gabion. Standard mesh sizes range from 6x6 inches to 12x12 inches, allowing for flexibility in design. Smaller mesh sizes can contain smaller rocks and prevent soil erosion, while larger mesh sizes facilitate the use of larger stones, which may be beneficial in certain aesthetic or structural applications.

gabion wire specification

Tensile Strength and Elongation

Tensile strength is a critical property of gabion wire, as it indicates how much load the wire can bear before breaking. High tensile strength is essential in applications where the gabion will experience significant force, such as in retaining structures. Manufacturers often provide information about the wire’s tensile strength in terms of pounds per square inch (PSI) or megapascals (MPa). A tensile strength of at least 350 MPa is generally recommended for the wire used in gabions.

Elongation refers to the wire's ability to stretch under load before breaking. A wire with good elongation properties can absorb shocks and stresses better than a more brittle wire. A minimum elongation percentage is often specified in the standard requirements, ensuring that the wire can deform without immediate failure.

Approvals and Standards

When specifying gabion wire, it's essential to refer to recognized industry standards. Specifications can vary by region but commonly include standards such as ASTM, ISO, and EN guidelines. Compliance with these specifications ensures that the wire meets quality and performance criteria established by industry experts, providing assurance to engineers, architects, and builders.

Conclusion

In conclusion, understanding gabion wire specifications is crucial for anyone involved in the design, construction, or installation of gabion structures. The type of wire, diameter, mesh size, tensile strength, and compliance with standards all play significant roles in the performance and longevity of gabions. By choosing the appropriate specifications, one can ensure that gabion structures not only meet functional needs but also contribute positively to the surrounding environment. As sustainability and eco-friendliness become more prominent in construction practices, gabions, supported by well-specified wire, will continue to be a valued solution.

-

Why a Chain Link Fence is the Right Choice

NewsJul.09,2025

-

Upgrade Your Fencing with High-Quality Coated Chicken Wire

NewsJul.09,2025

-

The Power of Fence Post Spikes

NewsJul.09,2025

-

The Best Pet Enclosures for Every Need

NewsJul.09,2025

-

Secure Your Property with Premium Barbed Wire Solutions

NewsJul.09,2025

-

Enhance Your Construction Projects with Quality Gabion Boxes

NewsJul.09,2025

Products categories