Nov . 15, 2024 13:36 Back to list

gabion wire specification

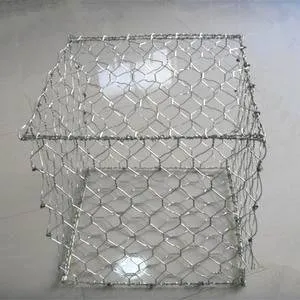

Gabion Wire Specification An Overview

Gabions are versatile structures used for erosion control, retaining walls, and landscape design, consisting of wire mesh cages filled with rocks or other materials. The effectiveness and longevity of gabions heavily depend on the specifications of the wire used to construct them. Understanding the wire specifications is crucial for engineers, architects, and contractors involved in gabion installations.

Wire Material

Typically, gabion wire is made from high-quality steel, with galvanized wire being the most common choice due to its corrosion-resistant properties. The galvanization process involves coating steel with a layer of zinc, which protects it from rusting, especially in harsh environmental conditions. In addition to galvanized wire, there are options for PVC-coated wire, which offers enhanced protection against abrasion and weathering, making it suitable for decorative or long-term applications.

Wire Diameter

The diameter of gabion wire is another critical specification affecting the structural integrity of the cages. Common wire diameters range from 2.0 mm to 4.0 mm, with thicker wires providing greater strength and resistance to deformation. The choice of wire diameter should consider factors such as the intended use of the gabion, environmental conditions, and expected loads.

Tensile Strength

gabion wire specification

Tensile strength refers to the maximum amount of tensile (pulling) stress that a material can withstand before failure. Gabion wire typically has a tensile strength of 350 to 500 MPa, which ensures durability and stability under various stress conditions. Higher tensile strength wire is recommended for applications subjected to significant forces, such as those in areas prone to heavy rainfall or flooding.

Mesh Size and Configuration

The mesh size and configuration are crucial for determining the overall performance of gabions. Standard mesh sizes range from 50 mm to 100 mm, with smaller sizes offering better containment of finer materials. The configuration of the mesh, whether square or rectangular, plays a vital role in the stability and aesthetics of the structure. Selecting the appropriate mesh size ensures that the fill material remains securely contained while allowing for proper drainage.

Manufacturing Standards

Gabion wire must conform to specific manufacturing standards to ensure quality and performance. Organizations such as ASTM (American Society for Testing and Materials) and EN (European Norms) provide guidelines that manufacturers follow. Adhering to these standards guarantees that the wire meets necessary requirements for tensile strength, ductility, and corrosion resistance.

Conclusion

In summary, gabion wire specifications are essential factors in the design and application of gabion structures. By selecting the right material, diameter, tensile strength, mesh size, and adherence to manufacturing standards, professionals can ensure the effectiveness, durability, and longevity of gabion installations. Understanding these specifications is vital for achieving successful project outcomes in landscape architecture, civil engineering, and environmental management.

-

Why a Chain Link Fence is the Right Choice

NewsJul.09,2025

-

Upgrade Your Fencing with High-Quality Coated Chicken Wire

NewsJul.09,2025

-

The Power of Fence Post Spikes

NewsJul.09,2025

-

The Best Pet Enclosures for Every Need

NewsJul.09,2025

-

Secure Your Property with Premium Barbed Wire Solutions

NewsJul.09,2025

-

Enhance Your Construction Projects with Quality Gabion Boxes

NewsJul.09,2025

Products categories