Jan . 23, 2025 05:52 Back to list

Barbed Wire With Galvanized Surface

Understanding the cost of wire mesh per square meter requires an in-depth look at various factors, each contributing to the price. As someone deeply entrenched in the world of construction materials, experience and expertise drive this comprehensive exploration into what really impacts the pricing of wire mesh.

Supplier reputation and product warranties are another layer in the cost structure. A well-established supplier with a history of supplying durable and high-quality wire mesh may charge more, but such costs can often be justified by the reduction in unforeseen repairs and replacements. Comprehensive product warranties add value, implying confidence in the product's long-term performance, which is essential in critical applications like construction or industrial filter systems. Seasonal demand trends also affect pricing. Some construction materials, including wire mesh, see price variations based on seasonal demand, with peak construction periods typically causing price surges due to increased demand. Technological advancements in wire mesh production, such as automated control systems and precision manufacturing, allow for higher efficiency and can translate to cost savings in some markets. These savings, however, depend on the supplier's investment in modern technology and their ability to pass these savings to consumers. It's also key to consider the impact of regulatory changes and tariffs, as these can cause significant price shifts in materials sourced internationally. Tariffs on imported metals may raise costs, while favorable trade agreements could lower prices. Lastly, the intended use of the wire mesh should align with the required specifications to optimize costs. Over-specification results in unnecessary expenses, while under-specification can compromise safety and performance. Accurate and comprehensive cost assessment of wire mesh per square meter empowers informed decision-making. By analyzing these multifaceted factors carefully, one can select the most suitable wire mesh that meets both budgetary constraints and project requirements, ensuring value and reliability over the lifespan of the product. This approach not only embodies expertise and authoritativeness but also builds trust through well-informed purchasing decisions.

Supplier reputation and product warranties are another layer in the cost structure. A well-established supplier with a history of supplying durable and high-quality wire mesh may charge more, but such costs can often be justified by the reduction in unforeseen repairs and replacements. Comprehensive product warranties add value, implying confidence in the product's long-term performance, which is essential in critical applications like construction or industrial filter systems. Seasonal demand trends also affect pricing. Some construction materials, including wire mesh, see price variations based on seasonal demand, with peak construction periods typically causing price surges due to increased demand. Technological advancements in wire mesh production, such as automated control systems and precision manufacturing, allow for higher efficiency and can translate to cost savings in some markets. These savings, however, depend on the supplier's investment in modern technology and their ability to pass these savings to consumers. It's also key to consider the impact of regulatory changes and tariffs, as these can cause significant price shifts in materials sourced internationally. Tariffs on imported metals may raise costs, while favorable trade agreements could lower prices. Lastly, the intended use of the wire mesh should align with the required specifications to optimize costs. Over-specification results in unnecessary expenses, while under-specification can compromise safety and performance. Accurate and comprehensive cost assessment of wire mesh per square meter empowers informed decision-making. By analyzing these multifaceted factors carefully, one can select the most suitable wire mesh that meets both budgetary constraints and project requirements, ensuring value and reliability over the lifespan of the product. This approach not only embodies expertise and authoritativeness but also builds trust through well-informed purchasing decisions.

Pervious:

Next:

Latest news

-

Why a Chain Link Fence is the Right Choice

NewsJul.09,2025

-

Upgrade Your Fencing with High-Quality Coated Chicken Wire

NewsJul.09,2025

-

The Power of Fence Post Spikes

NewsJul.09,2025

-

The Best Pet Enclosures for Every Need

NewsJul.09,2025

-

Secure Your Property with Premium Barbed Wire Solutions

NewsJul.09,2025

-

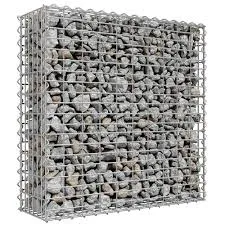

Enhance Your Construction Projects with Quality Gabion Boxes

NewsJul.09,2025

Products categories

NEED HELP?

Don' t Hesitate To Contact Us For More Information About Company Or Service

CONTACT US