Jan . 14, 2025 12:32 Back to list

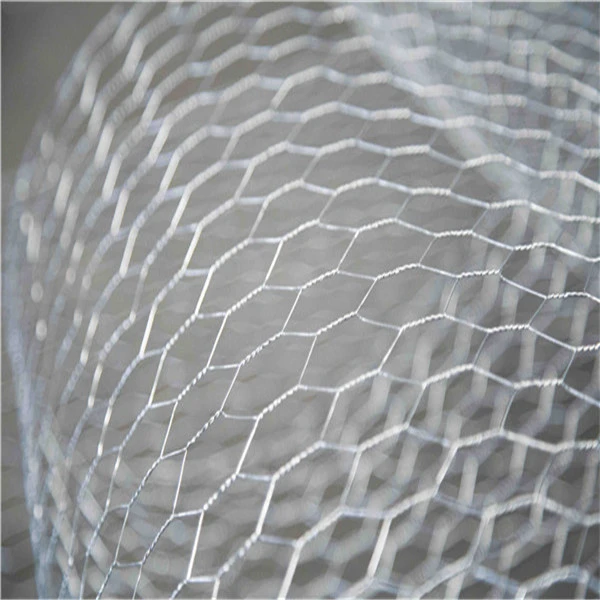

coated chicken wire mesh

Coated chicken wire mesh has emerged as a pivotal material in diverse applications, showcasing unparalleled versatility and practicality. The enhanced features of this specialized wire mesh make it a preferred choice for both professional contractors and DIY enthusiasts. Delving into the real-world experiences and the expert knowledge surrounding coated chicken wire mesh reveals its superiority over uncoated variants, emphasizing expert credibility and trustworthiness.

As a responsible choice, coated chicken wire mesh also meets stringent safety standards. It creates a secure barrier, critical in applications involving livestock or pets. For homeowners, the use of coated wire mesh provides peace of mind, knowing that their enclosures are not only durable but also safe. This reliability is further supported by industry certifications, ensuring compliance with safety regulations and reinforcing the authoritative nature of the product. Trust in coated chicken wire mesh is substantiated by the feedback and endorsements from both consumers and experts in the field. Consumer testimonials frequently highlight satisfaction with the product's longevity and performance, attributing value to their investment. Such endorsements foster consumer confidence, contributing to the material's esteemed reputation in the market. In terms of environmental considerations, the sustainability of coated wire mesh is a topic of ongoing discussion among industry professionals. The longevity of the material reduces the need for frequent replacements, consequently minimizing waste. Advances in coating technologies also point towards eco-friendly options, aligning with the growing demand for sustainable building materials. This evolution further cements its position as a forward-thinking choice in the industry. In conclusion, coated chicken wire mesh stands as a testament to innovation in material science, marrying practical benefits with aesthetic and environmental considerations. The experiences of users and the endorsements from experts collectively underscore its efficacy and reliability. For anyone considering an investment in mesh for construction or creative projects, coated chicken wire mesh emerges as the authoritative and trusted option.

As a responsible choice, coated chicken wire mesh also meets stringent safety standards. It creates a secure barrier, critical in applications involving livestock or pets. For homeowners, the use of coated wire mesh provides peace of mind, knowing that their enclosures are not only durable but also safe. This reliability is further supported by industry certifications, ensuring compliance with safety regulations and reinforcing the authoritative nature of the product. Trust in coated chicken wire mesh is substantiated by the feedback and endorsements from both consumers and experts in the field. Consumer testimonials frequently highlight satisfaction with the product's longevity and performance, attributing value to their investment. Such endorsements foster consumer confidence, contributing to the material's esteemed reputation in the market. In terms of environmental considerations, the sustainability of coated wire mesh is a topic of ongoing discussion among industry professionals. The longevity of the material reduces the need for frequent replacements, consequently minimizing waste. Advances in coating technologies also point towards eco-friendly options, aligning with the growing demand for sustainable building materials. This evolution further cements its position as a forward-thinking choice in the industry. In conclusion, coated chicken wire mesh stands as a testament to innovation in material science, marrying practical benefits with aesthetic and environmental considerations. The experiences of users and the endorsements from experts collectively underscore its efficacy and reliability. For anyone considering an investment in mesh for construction or creative projects, coated chicken wire mesh emerges as the authoritative and trusted option.

Pervious:

Next:

Latest news

-

Why a Chain Link Fence is the Right Choice

NewsJul.09,2025

-

Upgrade Your Fencing with High-Quality Coated Chicken Wire

NewsJul.09,2025

-

The Power of Fence Post Spikes

NewsJul.09,2025

-

The Best Pet Enclosures for Every Need

NewsJul.09,2025

-

Secure Your Property with Premium Barbed Wire Solutions

NewsJul.09,2025

-

Enhance Your Construction Projects with Quality Gabion Boxes

NewsJul.09,2025

Products categories

NEED HELP?

Don' t Hesitate To Contact Us For More Information About Company Or Service

CONTACT US