Jan . 22, 2025 01:03 Back to list

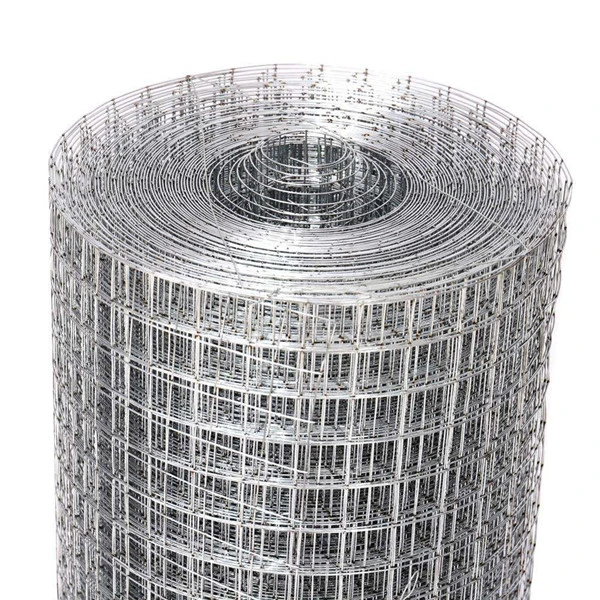

brc mesh

BRC mesh, or Building Reinforcement Concrete mesh, is more than just a construction material—it's a stepping stone to creating structures that speak volumes of durability and reliability. With over two decades of expertise in the construction industry, I've seen firsthand the transformative role that BRC mesh can play. It's not merely about reinforcing buildings; it's about ensuring that the very foundations of our society are steadfast and unyielding.

Trustworthiness stems from the BRC mesh’s consistent performance and compliance with construction regulations. Working with credible suppliers ensures that the material used is of the highest standard, significantly mitigating risks of structural failure. For contractors, this reliability translates into peace of mind, knowing that the structures they build are not only meeting but exceeding safety regulations. What sets BRC mesh apart is its role in sustainable building practices. As the construction industry leans towards environmentally friendly methods, BRC mesh stands out for its recyclability and efficiency in reducing concrete usage, thus lowering carbon footprints. Its use aligns with the global shift towards green building regulations, making it an ethical choice for modern construction. For those exploring BRC mesh for upcoming projects, partnering with seasoned experts can unlock its full potential. Developing a tailored plan that leverages its unique strengths ensures resilience against environmental stressors and compliance with stringent building codes. Continual updates in manufacturing processes also mean BRC mesh technology is advancing, offering even greater performance over time. In conclusion, BRC mesh is a cornerstone of modern construction, marrying strength with versatility, underpinned by decades of expertise and solid proof of reliability. As an advocate of its benefits, it is my professional commitment to promote its informed and responsible use in building a sustainable and safer future.

Trustworthiness stems from the BRC mesh’s consistent performance and compliance with construction regulations. Working with credible suppliers ensures that the material used is of the highest standard, significantly mitigating risks of structural failure. For contractors, this reliability translates into peace of mind, knowing that the structures they build are not only meeting but exceeding safety regulations. What sets BRC mesh apart is its role in sustainable building practices. As the construction industry leans towards environmentally friendly methods, BRC mesh stands out for its recyclability and efficiency in reducing concrete usage, thus lowering carbon footprints. Its use aligns with the global shift towards green building regulations, making it an ethical choice for modern construction. For those exploring BRC mesh for upcoming projects, partnering with seasoned experts can unlock its full potential. Developing a tailored plan that leverages its unique strengths ensures resilience against environmental stressors and compliance with stringent building codes. Continual updates in manufacturing processes also mean BRC mesh technology is advancing, offering even greater performance over time. In conclusion, BRC mesh is a cornerstone of modern construction, marrying strength with versatility, underpinned by decades of expertise and solid proof of reliability. As an advocate of its benefits, it is my professional commitment to promote its informed and responsible use in building a sustainable and safer future.

Pervious:

Next:

Latest news

-

Why a Chain Link Fence is the Right Choice

NewsJul.09,2025

-

Upgrade Your Fencing with High-Quality Coated Chicken Wire

NewsJul.09,2025

-

The Power of Fence Post Spikes

NewsJul.09,2025

-

The Best Pet Enclosures for Every Need

NewsJul.09,2025

-

Secure Your Property with Premium Barbed Wire Solutions

NewsJul.09,2025

-

Enhance Your Construction Projects with Quality Gabion Boxes

NewsJul.09,2025

Products categories

NEED HELP?

Don' t Hesitate To Contact Us For More Information About Company Or Service

CONTACT US