Feb . 08, 2025 07:56 Back to list

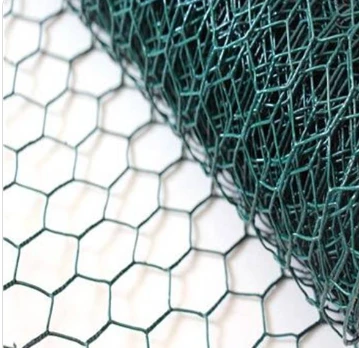

Welded Mesh Gabion

The 4x100 welded wire mesh, a critical component in the construction and manufacturing industry, stands out for its versatility and robustness. This mesh, defined by its grid dimensions of 4 inches by 100 feet, is intricately designed to offer optimal support in a myriad of applications—ranging from residential projects to complex industrial constructions.

From an authoritative standpoint, the use of 4x100 welded wire is endorsed by numerous construction standards and is often recommended by leading contractors and engineers who have firsthand experience of its benefits. Its compliance with safety standards and building codes further solidifies its position as a trusted component in construction projects of all scales. These advantages align squarely with the industry's demand for trustworthiness in construction materials. The emphasis on quality and performance guarantees that stakeholders—ranging from project managers to end-users—can rely on the safety and durability of structures built with this mesh. Consumers seek out products they can trust, and the 4x100 welded wire mesh, through documented performance and reliability, meets this criteria with flying colors. While the primary use of this welded wire is in construction, the burgeoning demand in agricultural and DIY sectors signifies its versatility. Farmers leverage this mesh in creating stable enclosures and pens, knowing well that it can withstand the environmental conditions typical of farm life. For home gardening enthusiasts, it offers a robust solution for plant support and fencing, proving that its utility extends beyond the conventional. In sum, the 4x100 welded wire mesh emerges as a product of choice for those seeking reliability and excellence in construction and beyond. Its combination of engineering precision, tested performance, and versatility makes it a backbone in industries where safety, strength, and sustainability are non-negotiable. For professionals tasked with the creation of enduring structures, this welded wire continues to be a preferred solution that delivers on its promise, every time.

From an authoritative standpoint, the use of 4x100 welded wire is endorsed by numerous construction standards and is often recommended by leading contractors and engineers who have firsthand experience of its benefits. Its compliance with safety standards and building codes further solidifies its position as a trusted component in construction projects of all scales. These advantages align squarely with the industry's demand for trustworthiness in construction materials. The emphasis on quality and performance guarantees that stakeholders—ranging from project managers to end-users—can rely on the safety and durability of structures built with this mesh. Consumers seek out products they can trust, and the 4x100 welded wire mesh, through documented performance and reliability, meets this criteria with flying colors. While the primary use of this welded wire is in construction, the burgeoning demand in agricultural and DIY sectors signifies its versatility. Farmers leverage this mesh in creating stable enclosures and pens, knowing well that it can withstand the environmental conditions typical of farm life. For home gardening enthusiasts, it offers a robust solution for plant support and fencing, proving that its utility extends beyond the conventional. In sum, the 4x100 welded wire mesh emerges as a product of choice for those seeking reliability and excellence in construction and beyond. Its combination of engineering precision, tested performance, and versatility makes it a backbone in industries where safety, strength, and sustainability are non-negotiable. For professionals tasked with the creation of enduring structures, this welded wire continues to be a preferred solution that delivers on its promise, every time.

Pervious:

Next:

Latest news

-

Why a Chain Link Fence is the Right Choice

NewsJul.09,2025

-

Upgrade Your Fencing with High-Quality Coated Chicken Wire

NewsJul.09,2025

-

The Power of Fence Post Spikes

NewsJul.09,2025

-

The Best Pet Enclosures for Every Need

NewsJul.09,2025

-

Secure Your Property with Premium Barbed Wire Solutions

NewsJul.09,2025

-

Enhance Your Construction Projects with Quality Gabion Boxes

NewsJul.09,2025

Products categories

NEED HELP?

Don' t Hesitate To Contact Us For More Information About Company Or Service

CONTACT US