Jan . 31, 2025 04:14 Back to list

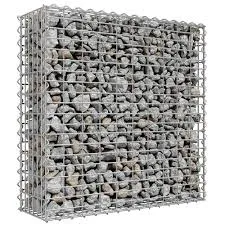

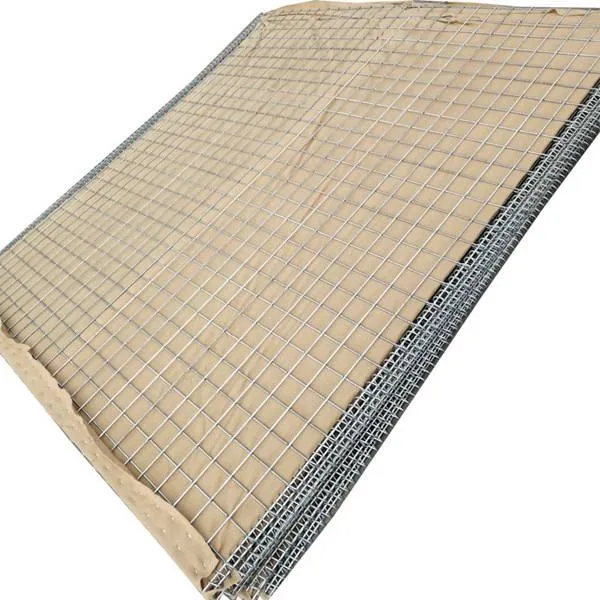

gabion welded wire mesh

Navigating the world of construction and fabrication, one quickly encounters the indispensable tool known as welded wire mesh. Specifically, 2 welded wire mesh, characterized by its robustness and versatility, has become a quintessential component for a plethora of projects globally.

The expertise inherent in choosing the correct type of welded wire mesh cannot be overstated. Professionals in the field emphasize selecting the appropriate gauge and material of the mesh to match the specific demands of a project. For instance, galvanized welded wire mesh offers enhanced rust resistance, making it a preferred option for outdoor applications exposed to the elements. Stainless steel variants, on the other hand, provide superior corrosion resistance and aesthetic appeal, ideal for projects where both functionality and appearance are paramount. These material choices, matched with precise manufacturing standards, bolster the authority of welded wire mesh as a cornerstone in engineering and construction. Its reliability is further underscored by rigorous testing and quality assurance practices, ensuring every batch meets stringent safety and performance criteria. This devotion to quality is a testament to the trustworthiness that professionals place in welded wire mesh products. Real-life applications and testimonials provide concrete evidence of the reliability and effectiveness of 2 welded wire mesh. From towering commercial skyscrapers to foundational reinforcements in residential buildings, its role in enhancing the durability and safety of structures is well documented. Construction managers and engineers often cite their personal experiences with the material, noting reduced construction times and increased efficiency, bolstered by the ease of installation and long-term performance benefits of welded wire mesh. In conclusion, 2 welded wire mesh stands as a paragon of excellence in construction materials. Its inherent strength, adaptability across applications, and trusted performance make it an invaluable asset. For professionals seeking to enhance their projects with a material that offers both reliability and integrity, 2 welded wire mesh emerges as the superior choice. While trends in building materials may evolve, the enduring legacy of welded wire mesh, supported by real-world applications and expert endorsements, ensures it remains at the forefront of modern engineering solutions.

The expertise inherent in choosing the correct type of welded wire mesh cannot be overstated. Professionals in the field emphasize selecting the appropriate gauge and material of the mesh to match the specific demands of a project. For instance, galvanized welded wire mesh offers enhanced rust resistance, making it a preferred option for outdoor applications exposed to the elements. Stainless steel variants, on the other hand, provide superior corrosion resistance and aesthetic appeal, ideal for projects where both functionality and appearance are paramount. These material choices, matched with precise manufacturing standards, bolster the authority of welded wire mesh as a cornerstone in engineering and construction. Its reliability is further underscored by rigorous testing and quality assurance practices, ensuring every batch meets stringent safety and performance criteria. This devotion to quality is a testament to the trustworthiness that professionals place in welded wire mesh products. Real-life applications and testimonials provide concrete evidence of the reliability and effectiveness of 2 welded wire mesh. From towering commercial skyscrapers to foundational reinforcements in residential buildings, its role in enhancing the durability and safety of structures is well documented. Construction managers and engineers often cite their personal experiences with the material, noting reduced construction times and increased efficiency, bolstered by the ease of installation and long-term performance benefits of welded wire mesh. In conclusion, 2 welded wire mesh stands as a paragon of excellence in construction materials. Its inherent strength, adaptability across applications, and trusted performance make it an invaluable asset. For professionals seeking to enhance their projects with a material that offers both reliability and integrity, 2 welded wire mesh emerges as the superior choice. While trends in building materials may evolve, the enduring legacy of welded wire mesh, supported by real-world applications and expert endorsements, ensures it remains at the forefront of modern engineering solutions.

Pervious:

Next:

Latest news

-

Why a Chain Link Fence is the Right Choice

NewsJul.09,2025

-

Upgrade Your Fencing with High-Quality Coated Chicken Wire

NewsJul.09,2025

-

The Power of Fence Post Spikes

NewsJul.09,2025

-

The Best Pet Enclosures for Every Need

NewsJul.09,2025

-

Secure Your Property with Premium Barbed Wire Solutions

NewsJul.09,2025

-

Enhance Your Construction Projects with Quality Gabion Boxes

NewsJul.09,2025

Products categories

NEED HELP?

Don' t Hesitate To Contact Us For More Information About Company Or Service

CONTACT US