Dec . 29, 2024 23:17 Back to list

Investigation of 1% and 2% Variations in Welded Wire Properties and Applications

Understanding 1% and 2% in Welded Wire A Comprehensive Overview

Welded wire is an essential component in various industries, ranging from construction to agriculture, providing structural integrity and security. Among the critical aspects of welded wire, the terms 1% and 2% specifically refer to the percentage of carbon content in the steel used to create the welded wire mesh. Understanding these percentages is crucial for selecting the right type of welded wire for your particular application.

The Importance of Carbon Content

Carbon content in steel is a significant determinant of the metal's properties, including its strength, ductility, and weldability. In the context of welded wire, the carbon content typically varies from low to medium levels based on the intended use. Wire with a lower carbon content (around 1%) is generally easier to weld and more ductile, making it suitable for applications where flexibility and ease of manipulation are critical. Conversely, wire with a higher carbon content (around 2%) tends to be stronger and more rigid, which can be advantageous in applications where load-bearing and durability are paramount.

Applications of 1% and 2% Welded Wire

1% welded wire is frequently used in scenarios that require a strong yet flexible material. It is commonly employed in agricultural settings for fencing, animal enclosures, and garden mesh. Its ease of welding and manipulation allows for quick setups and repairs, making it a favorite among farmers and gardeners. Additionally, 1% welded wire can be found in some construction applications, particularly in reinforcement applications where a balance between strength and flexibility is needed.

On the other hand, 2% welded wire excels in more demanding environments. The increased carbon content enhances the wire's tensile strength, making it ideal for heavy-duty applications. It is often used in construction projects for reinforcing concrete, in industrial settings for equipment protection, and in areas requiring a robust perimeter security solution. The rigidity provided by the higher carbon content makes it less susceptible to deformation under heavy loads, ensuring longevity and reliability in various structures.

1 2 in welded wire

Welding Considerations

When working with welded wire, it's essential to consider the appropriate welding techniques based on carbon content. Lower carbon content wires (1%) can be welded using simpler techniques like spot welding, while higher carbon content wires (2%) may necessitate more advanced methods such as MIG or TIG welding to achieve optimal results. The choice of welding method can significantly impact the integrity of the welds, thus influencing the overall structural performance of the welded wire installation.

Choosing the Right Welded Wire for Your Project

Selecting the right welded wire for a specific application involves understanding the environmental conditions, load requirements, and desired longevity of the material. For projects where flexibility is essential and the load requirements are moderate, 1% welded wire is often the best choice. Conversely, for projects demanding higher load-bearing capabilities and durability, 2% welded wire would be more appropriate.

Conclusion

In conclusion, understanding the differences between 1% and 2% welded wire is pivotal for anyone involved in construction, agriculture, or industrial applications. The choice of carbon content directly influences the properties of the wire, thus affecting its performance in various contexts. By adequately assessing the needs of your project, you can make an informed decision that will ensure structural integrity, safety, and efficiency in your applications. Whether you opt for the flexibility of 1% welded wire or the strength of 2% welded wire, knowing the implications of your choice is key to achieving the best results.

-

Why a Chain Link Fence is the Right Choice

NewsJul.09,2025

-

Upgrade Your Fencing with High-Quality Coated Chicken Wire

NewsJul.09,2025

-

The Power of Fence Post Spikes

NewsJul.09,2025

-

The Best Pet Enclosures for Every Need

NewsJul.09,2025

-

Secure Your Property with Premium Barbed Wire Solutions

NewsJul.09,2025

-

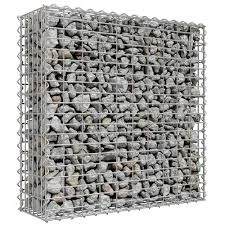

Enhance Your Construction Projects with Quality Gabion Boxes

NewsJul.09,2025

Products categories