Sep . 10, 2024 12:26 Back to list

12g welded mesh

The Versatility of 12g Welded Mesh in Construction and Beyond

Welded mesh, particularly in the specification of 12g, has emerged as a vital material in various sectors, primarily in construction and infrastructure development. The term 12g refers to the gauge of the wire used, indicating its thickness, which typically translates to approximately 2.0 mm in diameter. This measurement plays a crucial role in the mesh's strength and flexibility, making it suitable for a wide array of applications.

One of the most prominent uses of 12g welded mesh is in the reinforcement of concrete structures. When integrated into concrete, welded mesh provides an enhanced tensile strength that helps to distribute loads more evenly, reducing the risk of cracks and potential structural failure. Its uniform grid pattern acts as a stabilizing agent, which is particularly beneficial in slabs, beams, and walls. As a result, buildings and infrastructure like bridges and roads can withstand greater forces, such as those exerted by heavy loads or natural disasters.

Additionally, 12g welded mesh is utilized in fencing applications. Given its durability and resistance to corrosion, it is an ideal choice for agricultural and industrial fencing. This type of mesh effectively keeps livestock contained while preventing intruders and wildlife from entering sensitive areas. Its strength can deter animal tampering and withstand adverse weather conditions, making it a reliable solution for farmers and property owners alike.

12g welded mesh

Another notable application of 12g welded mesh is in the manufacturing of security products

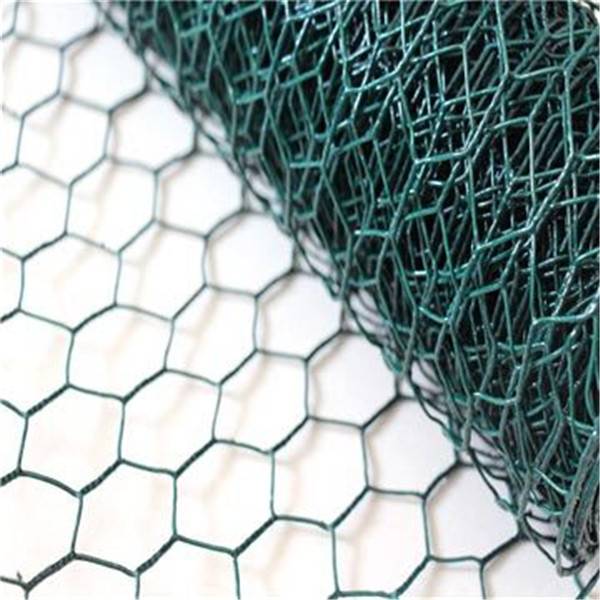

. Different types of barriers, along with partitions in warehouses and storage units, can be constructed using this mesh. It offers visibility while ensuring security against theft or unauthorized entry. Likewise, in the realm of construction sites, welded mesh can be employed as a protective barrier to ensure safety, preventing accidental falls and unauthorized access.Environmentally, 12g welded mesh is also gaining traction through its use in landscaping and architectural features. The mesh can be fabricated into trellises, fences, and other design elements, providing both aesthetic appeal and functionality. When coated with protective materials such as PVC, it becomes not only visually appealing but also versatile enough to blend seamlessly into any garden or public space.

From an installation perspective, working with 12g welded mesh is relatively straightforward. The welded intersections ensure that the mesh maintains its shape during handling and application, which can be a significant advantage over other types of fencing or reinforcing materials. Furthermore, its lightweight nature allows for easy transport and handling on job sites.

In summary, 12g welded mesh represents a perfect blend of strength, versatility, and ease of use across a myriad of applications. Whether it’s bolstering concrete in construction, providing reliable fencing, enhancing security, or contributing to aesthetically pleasing designs in landscaping, its characteristics cater to a spectrum of needs. As industries continue to evolve and seek materials that combine durability with sustainability, welded mesh will undoubtedly remain a staple in modern construction and design practices. As we move forward, exploring innovative uses and enhancements for welded mesh will further unlock its potential across multiple sectors.

-

The Versatility Of Hexagonal Wire Mesh For Your Projects

NewsAug.31,2025

-

The Strength And Durability Of Welded Wire Mesh

NewsAug.31,2025

-

The Essential Guide To Barbed Wire

NewsAug.31,2025

-

Secure Your Property With A High-Quality Wire Mesh Fence

NewsAug.31,2025

-

Protect Your Land With Durable Field Fencing Solutions

NewsAug.31,2025

-

Enhance Your Outdoor Space With Elegant Garden Gates

NewsAug.31,2025

Products categories