Feb . 11, 2025 21:41 Back to list

10x10 welded wire mesh

The use of 10x10 welded wire mesh has become increasingly common in various construction and industrial projects. Known for its versatility, durability, and cost-effectiveness, this product provides solutions across multiple fields, including agriculture, infrastructure, and architecture.

The authoritative appeal of 10x10 welded wire mesh is reinforced by its compliance with international standards. Such certification assures users that the product meets globally recognized benchmarks for safety and performance. Organizations like the American Society for Testing and Materials (ASTM) and the International Organization for Standardization (ISO) frequently define these standards, lending credibility to the use of the mesh in significant projects. Professionals prefer this mesh not only for its standard compliance but also for its historical reliability. Architects and engineers, when referencing past successful installations, frequently cite reports and case studies demonstrating the mesh’s performance under stress and its longevity over time. These documented successes enhance its reputation and authoritative status among construction materials. Trustworthiness and Durability The high trust placed in 10x10 welded wire mesh stems from its enduring performance over years of use. Clients and end-users often express satisfaction not just with the immediate results but with the long-term performance and low maintenance required over time. This reliability reduces overall lifecycle costs, making it an economically sound choice for large-scale and budget-sensitive projects. Moreover, industries trust it largely because of transparent manufacturing processes. Leading producers engage in rigorous quality control testing and openly share material specifications and testing results with customers. This openness fosters confidence and trust in the product’s ability to deliver as promised. Future Developments and Concluding Thoughts As the construction and agriculture industries evolve, so do the applications of 10x10 welded wire mesh. Researchers and manufacturers continuously innovate manufacturing processes to enhance mesh properties, aiming for lighter, stronger, and more environmentally friendly alternatives. These developments only serve to increase the mesh's applicability, making it a staple for future projects. In conclusion, the 10x10 welded wire mesh emerges as a pivotal material characterized by its reliable performance, customization capabilities, and compliance with international standards. Whether used in construction, agriculture, or other industrial applications, it remains a trusted component by professionals across the globe. Its combination of real-world practicality, expert manufacturing, authoritative endorsement, and trusted durability ensures that it will continue to be a preferred choice long into the future.

The authoritative appeal of 10x10 welded wire mesh is reinforced by its compliance with international standards. Such certification assures users that the product meets globally recognized benchmarks for safety and performance. Organizations like the American Society for Testing and Materials (ASTM) and the International Organization for Standardization (ISO) frequently define these standards, lending credibility to the use of the mesh in significant projects. Professionals prefer this mesh not only for its standard compliance but also for its historical reliability. Architects and engineers, when referencing past successful installations, frequently cite reports and case studies demonstrating the mesh’s performance under stress and its longevity over time. These documented successes enhance its reputation and authoritative status among construction materials. Trustworthiness and Durability The high trust placed in 10x10 welded wire mesh stems from its enduring performance over years of use. Clients and end-users often express satisfaction not just with the immediate results but with the long-term performance and low maintenance required over time. This reliability reduces overall lifecycle costs, making it an economically sound choice for large-scale and budget-sensitive projects. Moreover, industries trust it largely because of transparent manufacturing processes. Leading producers engage in rigorous quality control testing and openly share material specifications and testing results with customers. This openness fosters confidence and trust in the product’s ability to deliver as promised. Future Developments and Concluding Thoughts As the construction and agriculture industries evolve, so do the applications of 10x10 welded wire mesh. Researchers and manufacturers continuously innovate manufacturing processes to enhance mesh properties, aiming for lighter, stronger, and more environmentally friendly alternatives. These developments only serve to increase the mesh's applicability, making it a staple for future projects. In conclusion, the 10x10 welded wire mesh emerges as a pivotal material characterized by its reliable performance, customization capabilities, and compliance with international standards. Whether used in construction, agriculture, or other industrial applications, it remains a trusted component by professionals across the globe. Its combination of real-world practicality, expert manufacturing, authoritative endorsement, and trusted durability ensures that it will continue to be a preferred choice long into the future.

Pervious:

Next:

Latest news

-

Why a Chain Link Fence is the Right Choice

NewsJul.09,2025

-

Upgrade Your Fencing with High-Quality Coated Chicken Wire

NewsJul.09,2025

-

The Power of Fence Post Spikes

NewsJul.09,2025

-

The Best Pet Enclosures for Every Need

NewsJul.09,2025

-

Secure Your Property with Premium Barbed Wire Solutions

NewsJul.09,2025

-

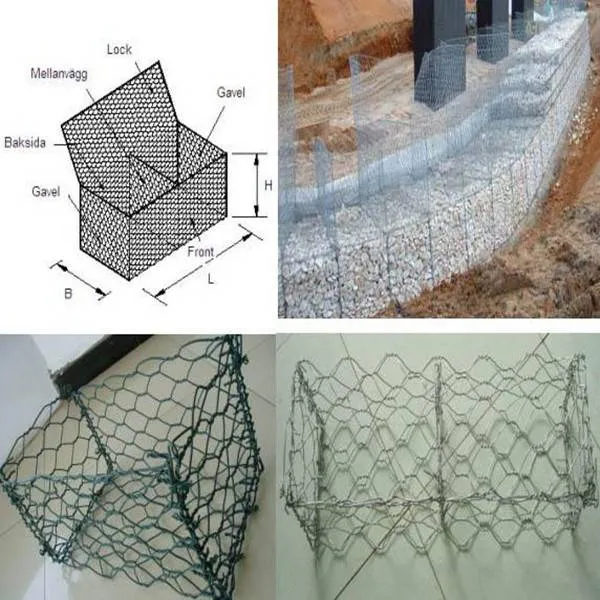

Enhance Your Construction Projects with Quality Gabion Boxes

NewsJul.09,2025

Products categories

NEED HELP?

Don' t Hesitate To Contact Us For More Information About Company Or Service

CONTACT US