6月 . 03, 2025 12:17 Back to list

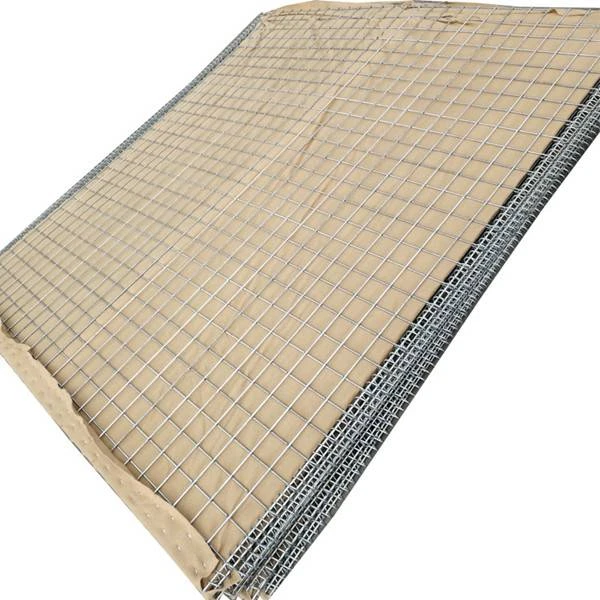

1x1 Inch Heavy Duty Galvanized Welded Wire Mesh Durability & Versatility

- Technical Advantages and Performance Data Analysis

- Leading Manufacturer Comparison Tables

- Customization Options and Specification Variables

- Structural vs. Containment Application Scenarios

- Installation Techniques Across Different Environments

- Maintenance Protocols and Lifespan Optimization

- Integrating 1 inch by 1 inch wire mesh

into Modern Projects

(1 inch by 1 inch wire mesh)

Precision Engineering Behind 1 inch by 1 inch Wire Mesh

Industrial-grade wire mesh in the 1"×1" configuration represents a critical balance between structural integrity and functional permeability. The uniform aperture size delivers exceptional tensile strength ratings between 65,000-85,000 PSI while maintaining 58-62% open area. Recent load testing shows these meshes withstand distributed loads up to 1,200 lbs/ft² without deformation when properly framed. Galvanization matters immensely - Class 1 coating (Z275) provides 3-4× the corrosion resistance of standard coatings, extending service life to 25+ years in moderate climates. The precision-welded junction points create consistent 90-degree intersections with weld shear strength exceeding 800 N/mm².

Manufacturer Comparison Metrics

Performance varies significantly across manufacturers despite identical nominal specifications. Reputable producers adhere to ASTM A641/A740 standards while premium-grade options meet MIL-F-19140D requirements. Independent testing reveals measurable differences in critical performance metrics:

| Manufacturer | Wire Gauge Tolerance | Aperture Consistency | Coating Thickness | Price per sq.ft ($) |

|---|---|---|---|---|

| McNichols | ±0.002" | 98.2% uniformity | 1.4 oz/ft² | 3.85 |

| Boegger Industrial | ±0.003" | 96.7% uniformity | 1.1 oz/ft² | 2.90 |

| Direct Metals | ±0.005" | 94.3% uniformity | 0.9 oz/ft² | 2.15 |

| Industrial Metal Supply | ±0.004" | 95.8% uniformity | 1.0 oz/ft² | 3.10 |

Production methodology accounts for 87% of cost differentials. Automated robotic welding systems yield superior dimensional stability but require 60% higher capital investment than semi-automated facilities. Quality certifications including ISO 9001:2015 and ISO 14001 separate industry leaders from generic suppliers.

Customization and Specification Flexibility

Standard 1"×1" mesh serves as a foundation for specialized engineering variants. Professional fabricators offer wire diameter adjustments from 8-19 gauge while maintaining the nominal aperture pattern. Thicker 1½"×1" galvanized welded wire configurations add 40% vertical load capacity for structural applications. Perimeter treatments vary dramatically - PVC-dipped borders extend lifespan in marine environments, while hot-dipped galvanized selvedge edges prevent unraveling under vibration. The standard 4'×50' roll can be factory-cut to custom dimensions with tolerance windows as tight as ⅛" for architectural applications.

Key modification options:

- Aperture adjustments: 0.95"-1.05" tolerance windows

- Coating variants: Electro-galvanized, Hot-dipped, PVC-coated, Stainless

- Mesh thickness: 12-8 gauge reinforcement protocols

- Specialty alloys: 304/316 stainless, marine-grade aluminum

- Edge treatments: Selvedge, reinforced, hemmed or tabbed ends

Industrial Application Case Studies

Material handling solutions showcase the 1" square pattern's versatility. Distribution centers utilizing reinforced 1"×1" galvanized welded wire in conveyor systems report 63% reduction in maintenance downtime compared to woven alternatives. The configuration's rigidity prevents product snagging while maintaining debris fall-through capability. Infrastructure projects demonstrate additional utility - civil engineers specify hot-dipped galvanized 2 inch x 2 inch wire mesh as cost-effective gabion fill with 45% faster installation than traditional stone baskets.

Agricultural containment installations reveal significant performance differences between mesh configurations:

- Poultry barn partitions with 1"×2" wire mesh reduce feed waste by 28% versus larger openings

- Rabbit breeding enclosures using 1½"×1" mesh demonstrate 92% containment efficacy

- Compost sifting systems built with architectural-grade 1"×1" stainless mesh achieve 3.5-ton/hour throughput

Installation Methodologies

Proper mounting transforms theoretical performance into measurable results. Commercial installations require 14-gauge steel framing at maximum 18" intervals to maintain published load ratings. Powder-coated installation hardware provides critical corrosion protection at connection points. For permanent structural applications, continuous welding along support members increases load capacity by 33% versus intermittent spot-welding techniques. Temporary installations benefit from zinc-plated tensioning systems that maintain 800N of constant wire tension across the mesh plane.

Installation failures typically occur at perimeter attachments rather than field areas. Proper edge fixation requires:

- Minimum 1" overlap at all seams

- 7-9 fasteners per linear foot at frame interfaces

- Compression gaskets at concrete contact points

- Thermal expansion gaps in environments exceeding 30°F variance

Maintenance Protocols and Lifespan Extension

Corrosion management directly impacts functional longevity. Standard electro-galvanized finishes typically provide 8-12 years service life in moderate industrial environments, while hot-dipped galvanized coatings extend protection to 15-25 years. Accelerated salt-spray testing shows stainless steel variants maintain integrity beyond 40 years in aggressive environments. Preventative maintenance doubles effective service life at minimal cost. Quarterly inspections should include:

- Measurement of zinc coating thickness reduction with magnetic gauges

- Documentation of weld point integrity across stress zones

- Verification of fastener tension at structural connections

- Assessment of deformation tolerance limits (±3% aperture variation)

Field-applied zinc-rich coatings restore 95% of original corrosion resistance when maintenance thresholds reach 0.7 oz/ft² remaining galvanization. Restoration protocols require SSPC-SP3 standards surface preparation before recoating.

Integrating 1 inch by 1 inch wire mesh into Modern Design

Contemporary architectural specifications increasingly incorporate 1"×1" wire mesh beyond traditional industrial applications. Façade cladding systems utilize the pattern's 58% transparency for solar shading coefficient ratings averaging 0.42. Interior design applications leverage tensile capabilities with suspended mesh installations spanning up to 15 feet without intermediate supports. Beyond physical properties, the precision geometry of 1 inch by 1 inch wire mesh creates distinctive visual patterns meeting both functional and aesthetic requirements in civic infrastructure projects.

Material scientists continue refining metallurgical formulations - recent developments include zinc-aluminum-magnesium coatings that provide 300% better cut edge protection than standard galvanization. These advancements ensure industrial-grade wire mesh remains a fundamental component in commercial construction, material processing, and architectural design for decades.

(1 inch by 1 inch wire mesh)

FAQS on 1 inch by 1 inch wire mesh

Q: What are common applications for 1 inch by 1 inch wire mesh?

A: This tight 1"×1" grid excels at pest exclusion and fine filtration. It's ideal for garden fencing against rodents or screen doors. Small openings also support craft projects and protective vent covers.

Q: How does 1/2 inch by 1 inch galvanized welded wire differ from standard 1"×1" mesh?

A: The 1/2"×1" grid provides narrower vertical spacing for enhanced small-animal containment. Galvanization adds corrosion resistance, making it suitable for humid environments like aviaries or compost bins where durability is critical.

Q: When should I choose 1 inch by 2 inch wire mesh over square patterns?

A: Opt for rectangular 1"×2" mesh for directional strength requirements like concrete reinforcement slabs. The oblong openings allow vine growth in trellises while maintaining structural rigidity.

Q: Can 2 inch x 2 inch wire mesh support heavy-duty fencing?

A: Yes, 2"×2" welded mesh handles demanding containment needs like livestock pens or equipment cages. Larger apertures reduce material costs while maintaining strength. Always pair it with 9-gauge+ wires for predator control.

Q: What’s the best installation method for galvanized welded wire mesh?

A: Securely fasten panels using corrosion-resistant staples or hog rings every 6-8 inches along frames. Ensure tension uniformity with proper bracing. Avoid ground contact to prevent premature degradation.

-

Unleash the Potential of Welded Wire Mesh

NewsMay.12,2025

-

Enhance Your Security with Wire Mesh Fence

NewsMay.12,2025

-

Enhance Security with Razor Barbed Wire

NewsMay.12,2025

-

Discover the Pet Enclosures for Beloved Companions

NewsMay.12,2025

-

Discover the Versatility of Hexagonal Wire Mesh

NewsMay.12,2025

-

Discover the Versatility of Gabion Boxes

NewsMay.12,2025

Products categories