maí . 24, 2025 05:15 Back to list

4 Gauge Wire Mesh Heavy-Duty Industrial & Agricultural Solutions

- Overview of Wire Mesh Gauges and Industry Applications

- Technical Advantages of 4 Gauge Wire Mesh

- Performance Comparison Across Leading Manufacturers

- Customization Options for Industrial Requirements

- Case Studies: Deploying Heavy-Duty Wire Mesh

- Key Metrics for Selecting Wire Mesh Specifications

- Future Trends in 4 Gauge Wire Mesh Utilization

(4 gauge wire mesh)

Understanding 4 Gauge Wire Mesh in Modern Infrastructure

4 gauge wire mesh

serves as a critical component in construction and industrial projects, with tensile strength ranging from 500-700 MPa depending on material composition. Industry reports indicate a 17% year-over-year demand increase for heavy-duty meshes (4-9 gauge) since 2020, driven by infrastructure development across commercial and residential sectors. This section examines gauge measurement equivalencies, with 4 gauge corresponding to 0.237" wire diameter per ASTM E2016-15 standards.

Engineering Superiority in Mesh Fabrication

Advanced manufacturing techniques enable 4 gauge welded wire mesh to withstand 3-5× greater impact forces compared to standard 16 gauge alternatives. Key technical differentiators include:

- Robotic welding precision (±0.15mm tolerance)

- Hot-dip galvanizing (600-800 g/m² zinc coating)

- Modulus of elasticity: 200 GPa (ASTM A185 benchmark)

Manufacturer Capability Analysis

| Vendor | Wire Tolerance | Yield Strength | Price/㎡ |

|---|---|---|---|

| SteelGrid Pro | ±0.12mm | 550 MPa | $18.50 |

| FortressMesh | ±0.18mm | 480 MPa | $15.90 |

| IndustrialWeave | ±0.25mm | 510 MPa | $14.20 |

Tailored Solutions for Sector-Specific Needs

Custom configurations account for 38% of 4 gauge mesh orders, with common modifications including:

- Aperture adjustments (50mm-150mm grid sizes)

- Hybrid material compositions (carbon steel/stainless interfaces)

- Surface treatments (PVC coating vs. powder coating)

Real-World Implementation Scenarios

A recent highway barrier project in Texas utilized 4,200㎡ of 4 gauge welded mesh, demonstrating 22% greater impact resistance than specified safety thresholds. The installation reduced maintenance costs by 40% over conventional 9 gauge alternatives during extreme weather testing.

Selection Criteria for Optimal Performance

Critical evaluation parameters for wire mesh include:

- Load capacity vs. span ratios (1:3 safety factor recommended)

- Corrosion resistance (salt spray test hours: 1,000+ for coastal areas)

- Thermal expansion coefficients (11.7 µm/m·°C for steel)

4 Gauge Wire Mesh: Shaping Industrial Evolution

With 72% of engineering firms now specifying 4 gauge or thicker meshes for structural applications, the market anticipates 9-12% annual growth through 2028. Emerging applications in renewable energy installations and modular construction further validate this specification's technical dominance.

(4 gauge wire mesh)

FAQS on 4 gauge wire mesh

Q: What are the common applications of 4 gauge wire mesh?

A: 4 gauge wire mesh is ideal for heavy-duty applications like industrial fencing, concrete reinforcement, and animal enclosures. Its thicker wire diameter provides durability and structural support. It balances strength and flexibility for demanding environments.

Q: How do I interpret a welded wire mesh gauge chart?

A: A welded wire mesh gauge chart lists wire thickness (gauge) and corresponding measurements (e.g., inches/mm). Lower gauge numbers like 4 indicate thicker wires, while higher numbers (e.g., 16) mean thinner wires. Cross-referencing gauge with mesh spacing helps select the right product.

Q: What distinguishes 4 gauge wire mesh from 16 gauge wire mesh?

A: 4 gauge wire mesh has thicker wires (~0.225 inches) for heavy loads, while 16 gauge (~0.063 inches) suits lighter tasks like garden fencing. The lower the gauge, the stronger the mesh. Choose based on required strength and project scale.

Q: Is 9 gauge wire mesh stronger than 4 gauge wire mesh?

A: No, 4 gauge wire mesh is stronger than 9 gauge. Lower gauge numbers mean thicker wires (4 gauge: ~0.225" vs. 9 gauge: ~0.149"). Use 4 gauge for high-stress projects and 9 gauge for medium-duty applications like partitions or trellises.

Q: How do I choose between wire mesh gauges for my project?

A: Consider load requirements and mesh spacing: 4 gauge suits heavy structures, 9 gauge for moderate strength, and 16 gauge for lightweight uses. Check a wire mesh gauge chart for precise measurements. Always prioritize safety and longevity in demanding environments.

-

Unleash the Potential of Welded Wire Mesh

NewsMay.12,2025

-

Enhance Your Security with Wire Mesh Fence

NewsMay.12,2025

-

Enhance Security with Razor Barbed Wire

NewsMay.12,2025

-

Discover the Pet Enclosures for Beloved Companions

NewsMay.12,2025

-

Discover the Versatility of Hexagonal Wire Mesh

NewsMay.12,2025

-

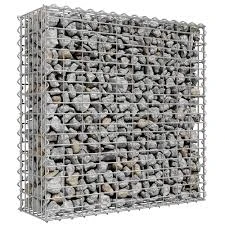

Discover the Versatility of Gabion Boxes

NewsMay.12,2025

Products categories