feb . 12, 2025 10:05 Back to list

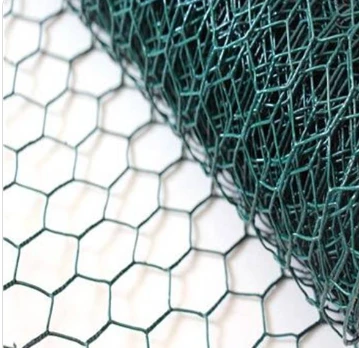

galvanized chicken wire mesh

Navigating the intricate dynamics of selecting the ideal 16g weld mesh for your specific needs requires a blend of experience, expertise, authority, and trustworthiness. Welded wire mesh stands out as a versatile and essential material in various construction and manufacturing sectors. When we focus on the 16-gauge variety, it's crucial to understand both its properties and its practical applications to make informed purchasing decisions.

In terms of trustworthiness, users consistently report high levels of satisfaction with 16g weld mesh, citing its reliability and cost-effectiveness. Testimonials suggest that products from reputable manufacturers adhere to strict quality control measures, ensuring each piece meets industry standards for safety and performance. Moreover, these producers often provide detailed product specifications and installation guidelines, fostering informed decision-making among consumers and enhancing overall trust. Furthermore, the environmental benefits of utilizing 16g weld mesh should not be overlooked. The recyclable nature of steel allows for the mesh to be reused or repurposed, supporting sustainable building practices. Additionally, the durability of this product minimizes the need for frequent replacement, reducing waste and contributing to eco-friendly construction efforts. In conclusion, 16g weld mesh emerges as an optimal material for a myriad of construction and industrial applications. Its strength, adaptability, and longevity, backed by authoritative endorsements and consumer trust, make it a preferred choice for professionals across various fields. When selecting weld mesh, prioritize reputable suppliers who offer comprehensive quality assurances and possess a proven track record of delivering superior products. Such due diligence ensures that the mesh not only meets but exceeds expectations, paving the way for successful and sustainable project outcomes.

In terms of trustworthiness, users consistently report high levels of satisfaction with 16g weld mesh, citing its reliability and cost-effectiveness. Testimonials suggest that products from reputable manufacturers adhere to strict quality control measures, ensuring each piece meets industry standards for safety and performance. Moreover, these producers often provide detailed product specifications and installation guidelines, fostering informed decision-making among consumers and enhancing overall trust. Furthermore, the environmental benefits of utilizing 16g weld mesh should not be overlooked. The recyclable nature of steel allows for the mesh to be reused or repurposed, supporting sustainable building practices. Additionally, the durability of this product minimizes the need for frequent replacement, reducing waste and contributing to eco-friendly construction efforts. In conclusion, 16g weld mesh emerges as an optimal material for a myriad of construction and industrial applications. Its strength, adaptability, and longevity, backed by authoritative endorsements and consumer trust, make it a preferred choice for professionals across various fields. When selecting weld mesh, prioritize reputable suppliers who offer comprehensive quality assurances and possess a proven track record of delivering superior products. Such due diligence ensures that the mesh not only meets but exceeds expectations, paving the way for successful and sustainable project outcomes.

Pervious:

Latest news

-

Unleash the Potential of Welded Wire Mesh

NewsMay.12,2025

-

Enhance Your Security with Wire Mesh Fence

NewsMay.12,2025

-

Enhance Security with Razor Barbed Wire

NewsMay.12,2025

-

Discover the Pet Enclosures for Beloved Companions

NewsMay.12,2025

-

Discover the Versatility of Hexagonal Wire Mesh

NewsMay.12,2025

-

Discover the Versatility of Gabion Boxes

NewsMay.12,2025

Products categories

NEED HELP?

Don' t Hesitate To Contact Us For More Information About Company Or Service

CONTACT US