velj . 06, 2025 03:39 Back to list

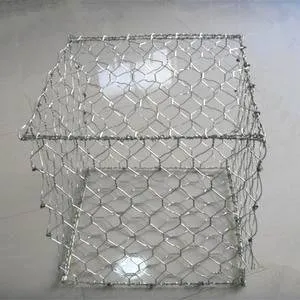

gabion welded wire mesh

In the specialized world of construction and manufacturing, W2 9 wire mesh is a noteworthy player offering unique advantages for a variety of applications. This type of wire mesh is distinctive for its robustness, partly defined by the gauge and composition of the wires that form a tight, durable grid. For anyone involved in building, landscaping, or industrial processes, understanding the specific attributes that make W2 9 wire mesh a superior choice can significantly enhance your project's outcome.

Trustworthiness in construction and materials is largely built on a track record of safety and reliability. W2 9 wire mesh epitomizes this trust, as evidenced by its compliance with leading international safety standards. Rigorous testing phases during production ensure that each batch meets the requisite tensile and pressure-bearing thresholds. For project managers and engineers, these assurances provide peace of mind, knowing that the materials will perform as expected under real-world conditions. Real-life experiences shared by industry professionals underline the advantages of incorporating W2 9 wire mesh in various projects. Engineers who have deployed this mesh often report enhanced project timelines due to the ease and speed of installation. They also note significant reductions in long-term maintenance costs, attributing this to the mesh’s resistance to corrosion and degradation—qualities that prolong the life of installations. Moreover, advancements in coating technologies, like galvanization and PVC coating, have further amplified the protective attributes of W2 9 wire mesh. These treatments offer additional layers of defense against environmental and chemical exposure, broadening the range of use cases. For instance, in marine applications where saltwater corrosion is a concern, these coatings ensure longevity and reduce the frequency of replacement or repair. In conclusion, W2 9 wire mesh is not just a material choice but a strategic advantage for those seeking durability, flexibility, and reliability in their projects. Its proven track record across multiple industries, coupled with continuous improvements in manufacturing processes, makes it a premier choice. For professionals seeking a solution that stands the test of time and environmental challenges, embracing the capabilities of W2 9 wire mesh could be a decisive factor in achieving exceptional project outcomes.

Trustworthiness in construction and materials is largely built on a track record of safety and reliability. W2 9 wire mesh epitomizes this trust, as evidenced by its compliance with leading international safety standards. Rigorous testing phases during production ensure that each batch meets the requisite tensile and pressure-bearing thresholds. For project managers and engineers, these assurances provide peace of mind, knowing that the materials will perform as expected under real-world conditions. Real-life experiences shared by industry professionals underline the advantages of incorporating W2 9 wire mesh in various projects. Engineers who have deployed this mesh often report enhanced project timelines due to the ease and speed of installation. They also note significant reductions in long-term maintenance costs, attributing this to the mesh’s resistance to corrosion and degradation—qualities that prolong the life of installations. Moreover, advancements in coating technologies, like galvanization and PVC coating, have further amplified the protective attributes of W2 9 wire mesh. These treatments offer additional layers of defense against environmental and chemical exposure, broadening the range of use cases. For instance, in marine applications where saltwater corrosion is a concern, these coatings ensure longevity and reduce the frequency of replacement or repair. In conclusion, W2 9 wire mesh is not just a material choice but a strategic advantage for those seeking durability, flexibility, and reliability in their projects. Its proven track record across multiple industries, coupled with continuous improvements in manufacturing processes, makes it a premier choice. For professionals seeking a solution that stands the test of time and environmental challenges, embracing the capabilities of W2 9 wire mesh could be a decisive factor in achieving exceptional project outcomes.

Pervious:

Next:

Latest news

-

The Versatility and Durability of PVC Coated Wire Mesh

NewsJun.10,2025

-

The Strength and Durability of Galvanized Welded Wire Mesh

NewsJun.10,2025

-

The Ideal Home for Your Pet with a Wire Dog Crate

NewsJun.10,2025

-

Secure Your Property with High-Quality Razor Wire

NewsJun.10,2025

-

PVC Coated Wire-- A Durable Solution for Every Application

NewsJun.10,2025

-

Enhance Your Home’s Entrance with Beautiful Garden Gates

NewsJun.10,2025

Products categories

NEED HELP?

Don' t Hesitate To Contact Us For More Information About Company Or Service

CONTACT US